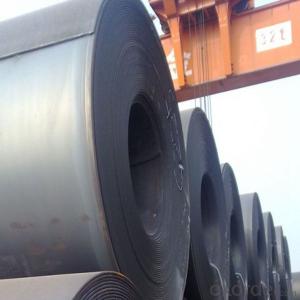

Steel Coils In Hot Rolled,Hot Rolled Steel Sheets SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC: 1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

For example,the MOQ of rebar will be 25-50MT,the galvanized steel pipe will be 10MT,the stainless steel pipe will 1-5MT.

DETAILED PICTURES FOR STEEL COILS

FAQ:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

Q:How about the delivery time?

A:Within 15-30days after receiving the deposit or L/C at sight.

Q:You are Factory or Trading Company?

A:We are factory,our main products include Steel plate,Steel Bar,Steel coils.

Q:What’s the MOQ?

A:Generally,the trail order will be accepted.The MOQ can be confirmed according to the different products.

- Q: What is the process of galvanizing steel sheets?

- The process of galvanizing steel sheets involves immersing them in a bath of molten zinc, which creates a protective coating on the surface of the steel. This coating prevents corrosion and extends the lifespan of the steel sheets.

- Q: Are steel sheets suitable for earthquake-prone regions?

- Yes, steel sheets are suitable for earthquake-prone regions. Steel is a strong and durable material that can withstand the forces generated during an earthquake. It has high tensile strength and flexibility, allowing it to absorb the seismic energy and deform without collapsing. Additionally, steel structures can be designed with proper reinforcements and connections to enhance their seismic performance. Therefore, steel sheets are a viable option for construction in earthquake-prone regions.

- Q: Are the steel sheets resistant to impact or denting?

- Yes, steel sheets are highly resistant to impact and denting. Steel is known for its exceptional strength and durability, making it one of the most reliable materials for various applications. The inherent properties of steel, such as its high tensile strength and toughness, provide excellent resistance against impact and denting. Additionally, steel sheets can be further enhanced with special coatings or treatments to increase their resistance to impacts or dents, making them even more reliable in demanding environments. Overall, steel sheets are a preferred choice for applications where impact resistance and denting are significant concerns.

- Q: Can steel sheets be used for railway applications?

- Yes, steel sheets can be used for railway applications. Steel sheets are commonly used in the construction of railway tracks, bridges, and other infrastructure due to their high strength, durability, and resistance to wear and tear. They can be formed into various shapes and sizes to meet the specific requirements of railway applications. Additionally, steel sheets can be easily welded, which allows for efficient and cost-effective installation and repair of railway components. Overall, steel sheets are a popular choice in the railway industry due to their excellent mechanical properties and ability to withstand heavy loads and harsh environmental conditions.

- Q: Are the steel sheets suitable for electrical applications?

- Yes, steel sheets are suitable for electrical applications as they have good conductivity and can be easily shaped into desired forms for various electrical components.

- Q: What are the different types of steel sheet finishes for decorative purposes?

- There are several different types of steel sheet finishes that are commonly used for decorative purposes. These finishes are applied to the surface of the steel sheet to enhance its appearance and provide a desired aesthetic effect. Some of the most popular steel sheet finishes for decorative purposes include: 1. Brushed Finish: This finish is achieved by brushing the surface of the steel sheet with a fine abrasive material, usually in a straight line pattern. It creates a smooth, satin-like appearance and is often used for architectural and interior design applications. 2. Mirror Finish: Also known as a polished finish, this finish creates a highly reflective surface that resembles a mirror. It is achieved by mechanically polishing the steel sheet and is commonly used in decorative applications such as furniture, lighting fixtures, and signage. 3. Patterned Finish: This finish involves embossing or etching a pattern onto the surface of the steel sheet. It can be achieved through various techniques, such as stamping, laser engraving, or chemical etching. Patterned finishes provide a decorative and textured appearance and are often used in applications like elevator panels, wall cladding, and decorative screens. 4. Colored Finish: Steel sheets can also be coated with a colored finish to add vibrancy and enhance their visual appeal. This can be achieved through processes such as powder coating, which involves applying a dry powder to the steel sheet and then curing it to create a durable, colored finish. Colored finishes are commonly used in architectural applications, including building facades and signage. 5. Antique Finish: This finish is designed to give the steel sheet an aged or weathered look, resembling antique metal. It is achieved through various techniques such as chemical treatments, patinas, or distressing. Antique finishes are often used in decorative applications to create a rustic or vintage aesthetic. These are just a few examples of the different types of steel sheet finishes available for decorative purposes. Each finish offers a unique appearance and can be customized to suit specific design preferences. The choice of finish depends on the desired look, application, and the level of durability required for the project.

- Q: What are the different surface treatments available for steel sheets?

- There are several surface treatments available for steel sheets, including galvanizing, electroplating, powder coating, and painting.

- Q: What's the difference between single rolling steel sheet and continuous rolling steel plate?

- Continuous plate refers to the hot rolling and cold rolling steel plate, rolling steel in rolling end is rolling roll, after Kaiping became a continuous plate after segmentation, due to the presence of curling and Kaiping rolling steel process, usually there are some residual stress, usually thin (less than 25mm) is narrow (usually below 2100mm).

- Q: Are the steel sheets suitable for architectural applications?

- Indeed, architectural applications can certainly make use of steel sheets. Steel, being a versatile material, presents numerous benefits for architectural purposes. It possesses strength, durability, and the ability to withstand harsh weather conditions, thus making it an excellent choice for various architectural elements like roofing, cladding, and facades. Furthermore, steel sheets provide architects with design flexibility, enabling the creation of unique and innovative structures. Moreover, steel is an environmentally sustainable material due to its recyclability and long lifespan, making it an eco-friendly option for architectural applications. All in all, steel sheets serve as a dependable and versatile choice for architects who desire to incorporate structural integrity, aesthetic allure, and sustainability into their designs.

- Q: What is the yield strength of steel sheets?

- The yield strength of steel sheets generally ranges from 250 to 550 megapascals (MPa), depending on the type and grade of steel used.

Send your message to us

Steel Coils In Hot Rolled,Hot Rolled Steel Sheets SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords