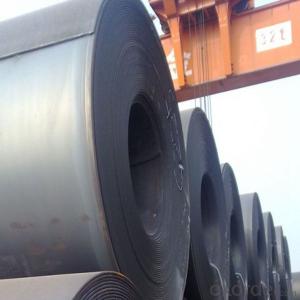

Hot Rolled Steel Sheets,Hot Rolled Plates,Good Quality SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR CARBON STEEL PLATE

Product | carbon steel plate price per ton |

Place of origin | Tianjin,China mainland |

MOQ | 25 tons |

Thickness | 1mm-200mm |

Width | 1000mm-3000mm |

Length | 1000mm-2000mm |

Application | widely |

Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

Tpye | Steel plate |

Surfacing | Coated |

Productive Technology | Hot Rolled & Cold Rolled |

Price | FOB USD 500-900 per ton |

Port | TIANJIN,SHANGHAI |

Payment Terms | L/C,T/T,Western Union,MoneyGram |

Product Ability | 1000 tons per month |

Delivery | 10 days after deposit or according to customers' quantity |

Packing | standard seaworthy export packing or as the request of customers |

TRADE TERMS :FOB, CFR, CIF

PAYMENT&DELIVERY FOR STEEL COILS/SHEETS

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

PICTURES:

EXPORT MARKET FOR STEEL COILS/SHEETS

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: How are steel coils inspected for formability using forming tests?

- Steel coils are inspected for formability using forming tests to assess their ability to be shaped into desired forms without any defects or failures. These tests are conducted to evaluate the material's mechanical properties and determine its suitability for specific applications. Forming tests involve subjecting the steel coil to various forming operations, such as bending, deep drawing, or stretch forming. The coil is typically cut into specified dimensions and then subjected to these operations using specialized equipment. The key objective is to simulate the actual forming process that the steel will undergo in real-world applications. During the forming tests, several parameters are closely monitored. These include the amount of force or load applied, the rate of deformation, and the resulting strain or deformation experienced by the steel. Additionally, the coil's response to these operations is observed, including any visible defects like cracks, fractures, or surface imperfections. By carefully analyzing the performance of the steel coil during the forming tests, various formability characteristics can be determined. These include the material's resistance to deformation, its ability to withstand strain without failure, and its tendency to exhibit defects under specific forming conditions. The results obtained from these tests provide valuable insights into the suitability of the steel coil for specific forming processes and applications. Moreover, advanced techniques such as digital image correlation and strain analysis may be employed to precisely measure and evaluate the strain distribution across the steel coil's surface. These techniques help identify regions of the coil that experience higher strain and potential failure points. In conclusion, steel coils are inspected for formability using forming tests that simulate the actual forming processes they will undergo. These tests assess various formability characteristics, including the material's resistance to deformation and its propensity for defects. The results obtained from these tests aid in determining the suitability of the steel coil for specific applications and guide the selection of appropriate forming parameters.

- Q: How are steel coils inspected for surface cleanliness during processing?

- Steel coils are inspected for surface cleanliness during processing through various methods such as visual inspection, magnetic particle inspection, and ultrasonic testing. These methods help identify any contaminants, defects, or surface irregularities that may affect the quality of the steel coils.

- Q: 2 refridgerator of similar model and same brand..one is stainless steel...the other is clear steel (cheaper)..so wat's the difference between the two?

- Stainless steel is different than regular (clear?) steel because is is an alloy, or combination, of steel and other elements. Stainles steel has 15% chromium, which is very resistant to rust than regular steel. That is why stainless is more expensive

- Q: What are the typical coil thickness options?

- The typical coil thickness options vary depending on the specific application and industry. However, common coil thickness options range from 0.005 inches to 0.250 inches (0.127mm to 6.35mm), with various intermediate thicknesses available.

- Q: How do steel coils resist corrosion?

- Steel coils resist corrosion due to the protective layer formed on their surface. This layer, known as a patina, acts as a barrier between the steel and the surrounding environment, preventing moisture and oxygen from reaching the metal and causing oxidation. Additionally, steel coils can be coated with corrosion-resistant materials such as zinc or paint to further enhance their resistance to corrosion.

- Q: i got a strip of steel from lowes how to sharpen it its not that thick its kinda slim but its heavyish its around 4'2 feet tall i cant get a whetstone or anything elsei have a brick , sand paper , and a hammer and some charcoal i was heating it up and trying to pound a edge into italso how to cut the steel to make a pointy curved tip any help appreciated and please tell me easy methodsplus its not sharp at all

- Comp is right- Lowe's sold you mild steel. Good for a lot of things, but holding an edge isn't one. If you want to make some sort of edged tool, try something like Smokey Mountain Knife Works or another online vendor. They have better blades, even some Damascus blades which will hold an edge much better. If you want to make your own blades, you'll need to start with better steel and build your own forge. I made one from a brake drum and a vacuum with a dimmer switch. You'll also need an anvil, something that may be a bit tough to locate. A couple of hammers and you can start forging blades. For something simpler, locate a place where you can learn blacksmithing and forging. Some art classes teach this at a community college, but not many. Check the site below and see if you can go with ABANA. ... Good luck!!

- Q: Can steel and/or stainless steel turn rusty ?

- Three answers you have stated that stainless steel doesn't rust. That isn't solely true, because there is one type that doesn't rust is often used on marine products such as yachts rigging's etc its' the 316 grade 304 302 301 do actually rust big time! Cheers!!

- Q: How are steel coils stored to prevent damage?

- Steel coils are typically stored in a way that prevents damage and ensures their integrity. One common method is to stack the coils in a horizontal position. This helps distribute the weight evenly across the coils, minimizing the risk of deformation or damage. In addition, wooden or steel dunnage is often placed between each layer of coils to provide support and prevent them from shifting during storage or transportation. To further protect the coils from damage, they are often stored indoors or in covered areas to shield them from exposure to the elements. This helps prevent rusting or corrosion, which can compromise the quality of the steel. If outdoor storage is necessary, the coils may be covered with weather-resistant tarps or protective coatings to minimize the impact of rain, snow, or sunlight. Furthermore, it is important to consider the stacking height to prevent excessive pressure on the lower coils. To avoid damage, coils are typically stacked in a way that ensures the weight from the upper layers is distributed evenly across the lower ones. This can include using specialized stacking equipment or racks designed to handle the weight and dimensions of the coils. Overall, proper storage of steel coils involves careful consideration of weight distribution, protection from the elements, and minimizing contact between coils to prevent damage and maintain their quality.

- Q: What are the different types of steel coil surface treatments for durability?

- The durability of the material can be enhanced through various types of steel coil surface treatments. 1. To achieve a protective zinc coating on the surface, the steel coil is immersed in a bath of molten zinc in the process of hot-dip galvanizing. This method not only provides excellent corrosion resistance but also extends the lifespan of the steel coil. 2. For indoor applications or when a thinner coating is desired, electro-galvanizing is preferred. This method involves electrodeposition of a thin layer of zinc onto the surface of the steel coil, offering good corrosion resistance. 3. By applying a dry powder paint to the steel coil's surface and curing it under heat, powder coating creates a durable and attractive finish. This finish is resistant to chipping, scratching, and fading, ensuring a uniform appearance. 4. To protect against corrosion, UV rays, and other environmental factors, organic coatings like acrylics, polyesters, or fluoropolymers are commonly applied to steel coils. These coatings not only enhance durability but also improve the aesthetics of the steel coil. 5. Chromate conversion coating involves applying a thin layer of chromate onto the steel coil's surface. This treatment provides corrosion resistance and improves the adhesion of subsequent paint or powder coating layers. Each of these surface treatments offers unique benefits in terms of corrosion resistance, durability, and appearance. The choice of treatment depends on the specific application requirements and the level of protection needed for the steel coil.

- Q: i like stainless steel guns, especially the SW 686 .357, i plan on getting one but my question is would polishing the stainless steel make the gun more prone to corrosion over leaving it as it is? and will the polished surface appear uneven after use and sitting? obviously all metal takes some sort of upkeep but is polished more high maintenance than non-polished?

- I use Mothers Mag polish also. The shine you get depends on the effort.... If you buffed a mirror finish it will dull in time... More work brings it back. On a SW you won't take off enough to make any difference as far as metal holding oil. I use a little Mothers whenever I clean my stainless revolver.... Takes the carbon ring off the cylinder face... I use old cotton socks and t shirts. You could use a Dremel to work the mag wheel polish if you want a bright finish.

Send your message to us

Hot Rolled Steel Sheets,Hot Rolled Plates,Good Quality SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords