Hot Rolled Steel Sheets SS400 Steel Plates SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

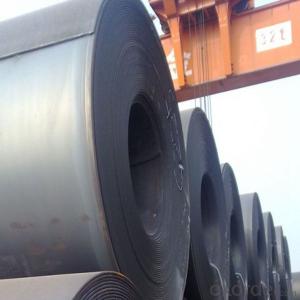

DETAILED PICTURES FOR STEEL COILS

EXPORT MARKET FOR STEEL COILS/SHEETS

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: Can steel sheets be used in the construction of bridges?

- Indeed, the utilization of steel sheets in the construction of bridges is possible. Due to its numerous beneficial characteristics, steel has become a prevalent material in bridge construction. Owing to their exceptional strength and durability, steel sheets are well-suited for enduring substantial loads and adverse weather conditions. Furthermore, their flexibility facilitates simpler fabrication and installation processes. Moreover, the ease with which steel sheets can be welded or bolted together makes them highly suitable for the construction of expansive structures such as bridges. In conclusion, steel sheets provide a dependable and cost-effective solution for bridge construction.

- Q: How to introduce carbon steel plate?

- Any of various steels that contain less than 2.11% of the mass of carbon but contain no alloying elements. Sometimes referred to as plain carbon steel or carbon steel. Carbon steel, also called carbon steel, refers to an iron carbon alloy with a carbon content of less than 2.11% Wc. Carbon steel, in addition to carbon, usually contains a small amount of silicon, manganese, sulfur and phosphorus.

- Q: Are steel sheets resistant to rot or decay?

- Yes, steel sheets are highly resistant to rot or decay.

- Q: How do steel sheets compare to other sheet materials like aluminum or stainless steel?

- Steel sheets have several advantages over other sheet materials like aluminum or stainless steel. Firstly, steel sheets are known for their exceptional strength and durability. They can withstand heavy loads and are resistant to impact, making them ideal for applications that require high strength and stability. Aluminum sheets, on the other hand, are relatively softer and less resistant to impacts, making them more suitable for lightweight applications. Secondly, steel sheets offer excellent corrosion resistance. While stainless steel sheets also possess this characteristic, steel sheets can be coated with protective layers or galvanized to enhance their corrosion resistance even further. This makes steel sheets more suitable for outdoor applications or environments with high humidity or exposure to harsh chemicals. Aluminum sheets, on the contrary, are prone to corrosion and typically require additional coating or treatment for protection. Moreover, steel sheets are more cost-effective compared to aluminum or stainless steel sheets. Steel is widely available and has a lower production cost, making steel sheets a more affordable option for many industries. Aluminum sheets, on the other hand, tend to be more expensive due to the higher cost of the raw material and the manufacturing process involved. Stainless steel sheets are also relatively expensive due to the additional alloying elements present in their composition. Lastly, steel sheets offer excellent fire resistance. They have a high melting point and do not easily catch fire or contribute to the spread of flames. This makes steel sheets the preferred choice for applications that require fire safety, such as construction or transportation. In summary, steel sheets stand out due to their exceptional strength, durability, corrosion resistance, cost-effectiveness, and fire resistance. While aluminum and stainless steel sheets have their own unique properties and applications, steel sheets are often favored for their superior overall performance in various industries.

- Q: Can steel sheets be used in marine applications?

- Yes, steel sheets can be used in marine applications. Steel is a common material used for constructing ships, offshore platforms, and other marine structures due to its high strength, durability, and resistance to corrosion in saltwater environments.

- Q: Are steel sheets resistant to chemical exposure?

- Yes, steel sheets are generally resistant to chemical exposure. Steel is known for its high resistance to corrosion and chemicals, making it suitable for various industrial applications where chemical exposure is a concern. However, the specific level of resistance may vary depending on the type and concentration of the chemical involved.

- Q: What are the different sheet metal joining techniques for steel sheets?

- There are several sheet metal joining techniques that can be used for steel sheets. Some of the most common ones include: 1. Welding: Welding is a popular and widely used technique for joining steel sheets. It involves melting the edges of the sheets and fusing them together using heat and pressure. Different types of welding techniques can be employed, such as arc welding, spot welding, or laser welding, depending on the specific application and requirements. 2. Riveting: Riveting is a fastening method where metal fasteners called rivets are used to hold the sheets together. It involves drilling holes in the sheets and inserting the rivets, which are then deformed to secure the joint. This technique provides strong and durable connections, making it suitable for structural applications. 3. Bolting: Bolting involves using bolts and nuts to connect steel sheets. Holes are drilled in the sheets, and bolts are inserted through the holes, with nuts tightened on the other side to hold the joint in place. Bolting offers the advantage of easy disassembly and reassembly, making it suitable for applications where frequent maintenance or repairs are required. 4. Adhesive bonding: Adhesive bonding is a technique where a strong adhesive or glue is used to bond steel sheets together. The adhesive is applied between the surfaces to be joined, and then pressure is applied to ensure proper bonding. Adhesive bonding provides a clean and aesthetically pleasing joint, without the need for drilling holes or using fasteners. 5. Clinching: Clinching is a cold joining technique that involves deforming the sheets to create a mechanical interlock. It is achieved by pressing the sheets together using a punch and die, which forms a raised feature on one sheet that interlocks with a depression on the other sheet. Clinching is a cost-effective and quick method for joining steel sheets without the need for additional materials. Each of these joining techniques has its own advantages and limitations, and the choice of technique depends on factors such as the specific application, required strength, durability, cost, and ease of assembly.

- Q: Is color steel plate the same as color steel tile?

- Tile color steel tile is used for color coated steel plate, pressure plate and the roller of cold bending into various wave types, it is suitable for industrial and civil buildings, warehouses, special buildings, large-span steel structure house roof, walls and wall decoration, has the characteristics of light weight, high strength, color rich, convenient construction, affluence earthquake, fire, rain, long service life, maintenance free, have been widely applied.

- Q: What is the cost of steel sheets compared to other metals?

- The cost of steel sheets can vary depending on factors such as the type of steel, thickness, and market conditions. However, generally speaking, steel sheets tend to be more cost-effective compared to many other metals due to the abundance of iron ore and efficient manufacturing processes.

- Q: How do you cut steel sheets?

- Steel sheets can be cut using various methods such as shearing, laser cutting, plasma cutting, or using a water jet cutter. The chosen method depends on factors like the thickness of the steel sheet, desired precision, and the available equipment.

Send your message to us

Hot Rolled Steel Sheets SS400 Steel Plates SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords