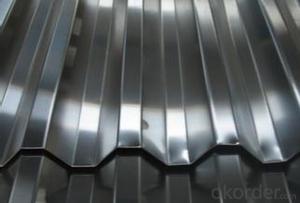

Prime quantity galvanized Steel Coils/Sheets from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot dip galvanized steel coil and sheet | |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

Thickness | 0.12-4.0mm |

Type of coating: | Galvanized |

Zinc coating | Z30-700g/m2 |

Surface Treatment | Chromed / Skin-pass/ Oiled/Slightly Oiled/ Dry/ Anti-fingerprint |

Surface structure: | Zero spangle / minimized spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-12 MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | Industrial panels, roofing and siding for painting |

Price terms | FOB,CFR,CIF |

Payment terms | T/T or L/C |

Delivery time | Within 30 days |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test,such as SGS/BV |

Technical data :

Hot dipped galvanized coil Technical Data

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

Hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: Can steel sheets be used for solar panel manufacturing?

- Yes, steel sheets can be used for solar panel manufacturing. Steel is a versatile and widely used material in various industries, including renewable energy. It has several advantages that make it suitable for solar panel manufacturing. Firstly, steel is a durable and robust material, which provides structural integrity to solar panels. It can withstand harsh weather conditions and protect the delicate photovoltaic (PV) cells inside the panels. This durability ensures a longer lifespan for the solar panels, reducing maintenance and replacement costs. Secondly, steel sheets can be easily fabricated into different shapes and sizes, allowing for customization based on the specific requirements of solar panel designs. This flexibility in manufacturing enables the creation of efficient and aesthetically pleasing solar panels. Furthermore, steel is a cost-effective material compared to other alternatives like aluminum or glass. It is widely available and has relatively low production costs, making it an economical choice for solar panel manufacturing. However, it is important to note that steel sheets used in solar panel manufacturing are typically coated with protective layers to enhance their corrosion resistance and prevent any adverse effects on the PV cells. These coatings protect the steel from environmental factors such as moisture or chemicals, ensuring the longevity and performance of the solar panels. In conclusion, steel sheets can indeed be used for solar panel manufacturing due to their durability, versatility, cost-effectiveness, and ease of fabrication. With appropriate coatings, steel can provide a reliable and efficient solution for the production of solar panels, contributing to the growth of the renewable energy sector.

- Q: Are steel sheets resistant to warping or bending?

- Yes, steel sheets are generally resistant to warping or bending due to their high tensile strength and stiffness. Steel is known for its durability and ability to withstand heavy loads without deforming. However, it is important to note that the resistance to warping or bending can vary depending on the thickness and quality of the steel sheet. Thicker steel sheets tend to be more resistant to bending or warping compared to thinner ones. Additionally, factors such as temperature changes and improper handling or installation can also affect the ability of steel sheets to resist warping or bending. Overall, steel sheets are commonly used in various industries due to their excellent resistance to warping or bending.

- Q: What are the environmental considerations of using steel sheets?

- One environmental consideration of using steel sheets is the carbon emissions associated with their production. Steel manufacturing processes, such as iron ore mining and steelmaking, contribute to greenhouse gas emissions, particularly carbon dioxide. Another consideration is the extraction of raw materials. The production of steel sheets requires significant amounts of natural resources, including iron ore and coal. Extracting these resources can have negative impacts on ecosystems, such as habitat destruction and water pollution. Additionally, the transportation and logistics involved in sourcing and delivering steel sheets can contribute to carbon emissions and air pollution. The long-distance transportation of steel sheets, especially if they are imported, can further increase the environmental footprint of their usage. Lastly, the disposal of steel sheets at the end of their life cycle is another environmental consideration. If not properly managed, steel waste can contribute to landfill accumulation and potentially contaminate soil and water sources. Overall, while steel sheets are a versatile and widely-used material in various industries, their production and usage have significant environmental implications that need to be carefully considered and mitigated.

- Q: Can steel sheets be used for security doors and windows?

- Yes, steel sheets can be used for security doors and windows. Steel is a strong and durable material that provides enhanced security and protection against break-ins and forced entry. It is commonly used in the construction of security doors and windows due to its strength and resistance to impact and tampering.

- Q: Are steel sheets resistant to impact or damage?

- Steel sheets possess remarkable strength and durability, attributes that render them exceptionally resistant to impact and damage. Their robust tensile strength enables them to endure substantial loads and withstand external forces without deformation or breakage. Thus, they find extensive use in critical applications that demand impact resistance, such as construction, automotive manufacturing, and industrial settings. Furthermore, steel sheets exhibit exceptional resilience against extreme temperatures, corrosion, and environmental factors, further enhancing their overall resistance to damage. However, it is worth noting that the degree of impact or damage resistance may vary depending on the thickness, quality, and composition of the steel sheet.

- Q: What are the common thicknesses for aluminum-coated steel sheets?

- The common thicknesses for aluminum-coated steel sheets range from 0.015 inches to 0.125 inches.

- Q: Can steel sheets be used for marine applications?

- Yes, steel sheets can be used for marine applications. Steel is a durable and strong material that can withstand the harsh conditions of the marine environment. It is commonly used for shipbuilding, offshore structures, and other marine equipment. Steel sheets can provide excellent corrosion resistance and structural integrity required for marine applications.

- Q: What is the maximum size available for steel sheets?

- The maximum size available for steel sheets can vary depending on the specific type and grade of steel being used, as well as the manufacturing capabilities of the steel supplier. However, in general, steel sheets can be manufactured in sizes ranging from small sheets measuring a few inches in width and length, to large sheets measuring several feet or even meters in width and length. The maximum size available for steel sheets can also be influenced by the transportation and handling limitations, as larger sheets may be more difficult to transport and maneuver. It is best to consult with a steel supplier to determine the maximum size available for steel sheets that meet your specific requirements.

- Q: Can steel sheets be used in HVAC systems?

- Yes, steel sheets can be used in HVAC systems. Steel is a commonly used material in HVAC systems due to its strength, durability, and resistance to corrosion. Steel sheets are often used for the fabrication of ductwork, which is an essential component of HVAC systems. The ductwork distributes the conditioned air throughout a building, ensuring proper ventilation and temperature control. Steel sheets are preferred for duct fabrication as they can withstand the high pressure and temperature conditions commonly found in HVAC systems. Additionally, steel sheets can be easily formed and joined together, allowing for the customization and installation of ductwork in various sizes and shapes. Overall, steel sheets are a suitable material choice for HVAC systems, providing reliable performance and longevity.

- Q: How do you prevent galvanic corrosion when using steel sheets with other metals?

- To prevent galvanic corrosion when using steel sheets with other metals, several measures can be taken. One effective method is to use a protective barrier, such as a non-conductive coating or paint, on the steel sheets. This barrier acts as a physical barrier between the steel and the other metals, preventing direct contact and the subsequent corrosion. Additionally, using insulating materials, such as rubber gaskets or plastic spacers, can also help isolate the steel sheets from the other metals. Another approach is to apply sacrificial anodes, such as zinc or magnesium, to the steel sheets. These anodes will corrode instead of the steel, protecting it from galvanic corrosion. Regular maintenance and inspection of the steel sheets and their connections are also crucial to detect any potential issues and address them promptly.

Send your message to us

Prime quantity galvanized Steel Coils/Sheets from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords