Galvanized Steel Sheet for Roofing Purpose Q235 SS400 GRADE D

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction of Galvanized Steel Sheet for Roofing Purpose Q235 SS400:

Plain galvanized sheets are used for automotive body building, panels, electrical appliances like refrigerator, washing machine, and use for advertisement panels. Etc.

The thickness ranges from 0.5mm to 2mm in thickness and 900mm to 1250mm in width.

The coating also ranges from 120gsm to 240gsm

Galvanized plain sheets are manufactured using premium quality material which provides high tensile strength and makes them seepage resistant. GC sheets prove to be a cost effective solution for various construction purposes such as roofing, side-walls, partitions and panels.

2.Main features of Galvanized Steel Sheet for Roofing Purpose Q235 SS400:

.Corrugated Galvanized sheets are mainly used for roofing purpose.

.Corrugated galvanized sheets are generally termed as G.C. Sheet.

3. Galvanized Steel Sheet for Roofing Purpose Q235 SS400 Images:

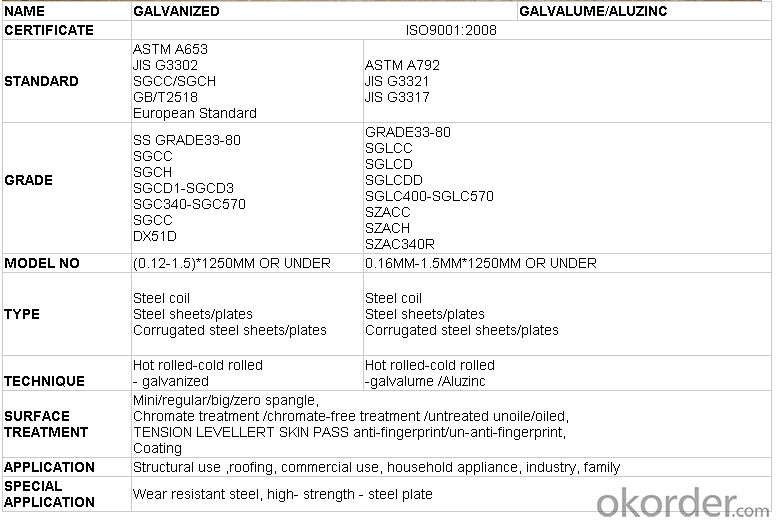

4. Galvanized Steel Sheet for Roofing Purpose Q235 SS400 Specification:

5.Our Factory:

6.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets inEurope,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What's the effect of water stopping between steel plate and water stop strip? What's the difference between the process and the sealing process?

- Water stopping principle: the water stop bar is expanded by water absorption and then squeezed with concrete to stop the void.Construction technology: the stop bar is square long strip, and parallel lap method is adopted when connecting. No break point can be left in the middle. Construction units in order to facilitate, often like to use the water bar, concrete pouring in the completion of the pressure on the wall concrete pouring surface, or reserved groove, two times mosaic.Good and bad analysis: simple construction, less investment, relatively economic. But there is no water stopping effect and the water stopping steel plate is good. There are many unforeseen problems during the construction process. One is that the reinforcing bars are not close enough to be laid. Two is the time is too long, moisture absorption expansion, the impact of the effect, especially in the rainy season, air humidity, rainfall, water retention is worse. Three construction joints are not smooth, poor contact. Usually, this method is not ideal for stopping water. For example, when the water stop bar is installed, the retaining of the groove is too large to be fixed effectively; the small inlay is not in place; when the concrete is poured, the utility model is easy to shift under the action of the concrete buoyancy.

- Q: Are steel sheets suitable for high-vibration environments?

- Yes, steel sheets are suitable for high-vibration environments. Steel is a strong and durable material that can withstand vibrations without experiencing significant deformation or damage. It is commonly used in industries such as construction, automotive, and aerospace, where high-vibration environments are common. Additionally, steel sheets can be designed and manufactured to have vibration-damping properties, further enhancing their suitability for such environments.

- Q: Are the steel sheets resistant to graffiti or vandalism?

- Yes, steel sheets are highly resistant to graffiti or vandalism. Due to their robust and durable nature, steel sheets serve as a formidable deterrent against acts of vandalism or graffiti. The smooth surface of steel sheets makes it difficult for vandals to adhere spray paint or other graffiti materials, and even if they manage to apply it, the paint can be easily removed with proper cleaning techniques without leaving any trace. Additionally, steel sheets are highly resistant to scratching or etching, which further prevents any form of vandalism. Overall, choosing steel sheets for surfaces that are prone to graffiti or vandalism offers excellent protection and minimizes the need for costly repairs or repainting.

- Q: How do steel sheets perform in high-wind areas?

- Due to their inherent strength and durability, steel sheets are highly effective in high-wind areas. They offer excellent resistance against strong winds and are commonly used for roofs and walls in regions prone to hurricanes, tornadoes, or severe weather. The robust nature of steel allows it to withstand high wind speeds without any deformation or damage. Steel sheets are specifically designed and manufactured to meet wind load requirements, ensuring their ability to endure the forces generated by strong winds. This makes them a dependable choice for structures in high-wind areas. Furthermore, steel sheets are securely fastened to the underlying structure, further enhancing their resistance to wind. Proper installation techniques and fasteners are crucial in ensuring the sheets remain intact during extreme weather conditions. Additionally, steel sheets can be designed with interlocking profiles, providing an extra layer of protection against wind-driven rain and debris. In terms of maintenance, steel sheets require minimal upkeep in high-wind areas. They are resistant to rot, insect damage, and decay, which are major concerns in regions with high humidity and frequent rainfall. Moreover, steel sheets have a long lifespan, offering long-term protection against wind damage. However, it is vital to consider the overall design and construction of a building when evaluating the performance of steel sheets in high-wind areas. The structural integrity of the entire system, including the framing and connections, should be properly engineered to withstand expected wind loads. Sufficient bracing and reinforcement should also be incorporated into the building's design to ensure optimal performance and safety. In conclusion, steel sheets are an excellent option for high-wind areas due to their strength, durability, and ability to resist wind damage. When installed correctly and integrated into a well-designed structure, steel sheets provide reliable protection against strong winds, making them a preferred material in regions prone to severe weather conditions.

- Q: Can steel sheets be used for water tanks or storage containers?

- Yes, steel sheets can be used for water tanks or storage containers. Steel is a durable and strong material that can withstand the pressure and weight of holding water or storing various materials. It is commonly used in the construction of water tanks and storage containers due to its resistance to corrosion, ability to maintain structural integrity, and ease of maintenance. Steel sheets can be fabricated into different shapes and sizes to meet specific requirements, making them versatile for various applications. Additionally, steel is a recyclable material, which adds to its sustainability and environmental benefits.

- Q: How do steel sheets handle static electricity?

- Steel sheets possess excellent electrical conductivity, including the conduction of static electricity. This is due to their high electrical conductivity, allowing them to swiftly eliminate any static charge that accumulates on their surfaces. The effectiveness in handling static electricity is mainly attributed to the presence of unbound electrons within the atomic structure of the steel. When a static charge is applied to a steel sheet, these unbound electrons promptly relocate themselves, nullifying the charge and preventing the accumulation or release of static electricity. Furthermore, steel sheets are frequently coated with a thin protective layer, such as zinc or paint, which further enhances their capacity to dissipate static charges. In general, steel sheets are renowned for their dependable performance in managing static electricity and are commonly utilized in various industrial applications where electrostatic discharge may pose risks to safety or cause damage.

- Q: What does "Z" mean to the performance of steel?

- Z to the plate, also known as "Z" to steel, also known as "lamellar steel tearing resistant steel", that is usually referred to as Z performance.The use of welded connections in steel structure, when the sheet thickness of not less than 40 mm and bear along the thickness direction of the tension, to avoid lamellar tearing when welding, the lamellar tearing of steel (commonly referred to as the "Z to steel"). There is a lamellar tearing problem in thick plates, so Z performance test is necessary.

- Q: What is the difference between a galvanized and painted steel sheet?

- A galvanized steel sheet is one that has been coated with a layer of zinc to protect it from corrosion. This process, known as galvanization, involves immersing the steel sheet in a bath of molten zinc, which forms a bond with the underlying steel. This zinc coating acts as a sacrificial anode, meaning that it corrodes instead of the steel when exposed to elements such as moisture and oxygen. As a result, galvanized steel sheets have excellent corrosion resistance and can last for a long time in outdoor environments. On the other hand, a painted steel sheet is one that has been coated with a layer of paint to provide both aesthetic appeal and additional protection against corrosion. The paint acts as a barrier between the steel surface and the surrounding environment, preventing moisture and other corrosive substances from coming into direct contact with the steel. This helps to prolong the lifespan of the steel sheet and maintain its appearance. In terms of appearance, galvanized steel sheets have a characteristic silver-gray color due to the zinc coating, while painted steel sheets can come in a wide range of colors depending on the type of paint used. Galvanized steel sheets also have a textured surface due to the presence of the zinc coating, while painted steel sheets can have a smoother or textured finish depending on the application technique. Ultimately, the main difference between galvanized and painted steel sheets lies in the method of protection against corrosion. Galvanized steel relies on the sacrificial corrosion of zinc, while painted steel relies on the barrier effect of the paint. The choice between the two depends on factors such as the specific application, aesthetic requirements, and the level of corrosion resistance needed.

- Q: How do steel sheets compare to other materials like aluminum or copper?

- Steel sheets have several advantages over other materials like aluminum or copper. First, steel is generally stronger and more durable, making it suitable for a wide range of applications. Additionally, steel has a higher melting point than aluminum, making it better suited for high-temperature environments. Steel sheets are also relatively more affordable and readily available compared to copper, making them a cost-effective choice for many industries. However, it's important to consider specific requirements and characteristics of each material before making a final comparison.

- Q: What are the standard sizes of steel sheets?

- The standard sizes of steel sheets can vary depending on the type and purpose, but some common dimensions include 4 feet by 8 feet, 5 feet by 10 feet, and 6 feet by 20 feet.

Send your message to us

Galvanized Steel Sheet for Roofing Purpose Q235 SS400 GRADE D

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords