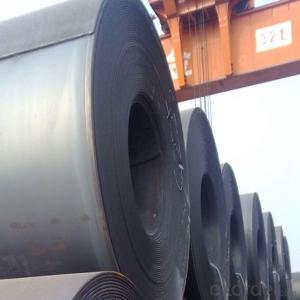

Hot Rolled Steel Coils Steel Sheets SS400 Good Quality

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC:

1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

DETAILS:

Thickness | 0.5-100mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

Tehnique | Hot rolled;cold rolled |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, North/South America, Europe, Asia,Africa etc |

Certificate | BV,SGS,MTC |

Delivery time | 30-45days after confirming the order |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

PAYMENT&DELIVERY FOR STEEL COILS/SHEETS

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

FAQ

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: What safety precautions should be taken when handling steel sheets?

- When handling steel sheets, it is important to follow a few safety precautions. First, always wear personal protective equipment such as gloves, safety glasses, and steel-toe shoes to protect yourself from potential injuries. Secondly, ensure that the work area is well-ventilated as steel sheets may release harmful fumes when heated or welded. Additionally, use proper lifting techniques to avoid strains or back injuries, as steel sheets can be heavy. Lastly, store steel sheets in a secure and organized manner to prevent them from falling or causing accidents.

- Q: Are steel sheets suitable for high-temperature applications?

- Yes, steel sheets are generally suitable for high-temperature applications due to their high melting point and excellent heat resistance.

- Q: Are steel sheets available in textured finishes?

- Steel sheets are indeed available with textured finishes. Various processes, such as embossing, etching, or brushing, can be used to achieve these textured finishes. These techniques create patterns or textures on the surface of the steel sheet, resulting in a distinctive and visually pleasing appearance. In addition to enhancing the aesthetic appeal, these textured finishes offer functional advantages, such as improved grip, reduced glare, and increased durability. Depending on the specific application and design preferences, different types of textures can be applied to steel sheets.

- Q: How do steel sheets compare to glass sheets?

- Different applications require distinct characteristics in steel sheets and glass sheets. To begin with, steel sheets are renowned for their strength and durability, enabling them to bear heavy loads and resist impact and damage effectively. Consequently, they are well-suited for construction purposes, including building manufacturing, bridge construction, and machinery development. Furthermore, steel sheets provide excellent fire protection and can withstand extreme weather conditions. On the other hand, glass sheets are highly valued for their transparency and aesthetic appeal. By allowing natural light to pass through, they create a bright and open atmosphere. Consequently, glass sheets are commonly used in windows, doors, and architectural structures to enhance visibility and the visual appeal of a space. Additionally, glass sheets possess excellent thermal insulation properties, which aid in reducing energy consumption in buildings. When it comes to maintenance, steel sheets require minimal upkeep due to their corrosion resistance and infrequent need for cleaning. However, they may require painting or protective coatings to prevent rusting. Conversely, glass sheets may need regular cleaning to maintain their transparency and appearance. Moreover, they are more prone to scratching and breakage compared to steel sheets. Lastly, cost must be considered. Generally, steel sheets have a lower initial cost compared to glass sheets. However, the overall cost may vary depending on factors such as size, thickness, and quality. Additionally, the installation and maintenance costs should also be taken into account. In conclusion, steel sheets and glass sheets possess unique characteristics and properties. The choice between the two depends on specific project requirements, including strength, transparency, aesthetics, maintenance, and cost considerations.

- Q: How long do steel sheets last?

- The lifespan of steel sheets can vary depending on various factors such as the quality of the steel, the environment in which they are used, and the maintenance provided. However, with proper care and maintenance, steel sheets can last for several decades, if not longer.

- Q: Can steel sheets be used for elevator panels or interiors?

- Yes, steel sheets can be used for elevator panels or interiors. Steel is a durable and versatile material that is commonly used in elevator construction due to its strength and aesthetic appeal. It can be fabricated into various shapes and sizes to create sleek and modern elevator panels and interiors.

- Q: Are the steel sheets suitable for high-temperature applications?

- Steel sheets are generally considered suitable for applications with high temperatures. Steel is renowned for its exceptional strength and durability, making it a favored choice among various industries that require materials capable of withstanding extreme heat. Steel sheets can be produced with high melting points and can maintain their structural integrity even when exposed to intense heat. Moreover, steel exhibits commendable thermal conductivity, enabling efficient heat dissipation from the surface. However, it is crucial to take into account the particular grade and composition of the steel sheets, as certain alloys are specifically engineered for high-temperature applications. It is advisable to seek advice from a materials engineer or specialist to ensure that the chosen steel sheets are appropriate for the specific high-temperature environment.

- Q: How are steel sheets joined together?

- Steel sheets can be joined together through various methods such as welding, riveting, bolting, or using adhesives.

- Q: What are the different sheet metal welding techniques for steel sheets?

- Steel sheets can be joined using various sheet metal welding techniques. The most commonly used methods are as follows: 1. MIG welding, also known as Gas Metal Arc Welding (GMAW), involves the use of a continuous wire electrode to create an arc and join the steel sheets. This technique is versatile and efficient, suitable for both thin and thick sheets. 2. TIG welding, or Gas Tungsten Arc Welding (GTAW), utilizes a non-consumable tungsten electrode to create an arc and join the steel sheets. It produces high-quality welds with excellent control, making it ideal for thin or delicate sheet metal. 3. Resistance Spot Welding (RSW) involves applying pressure and passing a high electrical current through the steel sheets using two electrodes. This causes the sheets to fuse together swiftly and cost-effectively. It is commonly used in the automotive and manufacturing industries. 4. Laser Welding employs a high-energy laser beam to melt and join the steel sheets. The technique offers precise control, high welding speeds, and minimal heat input, making it suitable for thin and highly reflective materials. 5. Electron Beam Welding (EBW) utilizes a focused beam of high-velocity electrons to create a weld. It offers deep penetration and is often used for thick steel sheets or applications requiring high-quality welds. 6. Plasma Arc Welding (PAW) is similar to TIG welding but utilizes a plasma arc to create a weld. This technique provides higher welding speeds and can be used for both thick and thin steel sheets. The choice of welding technique depends on various factors such as the thickness of the steel sheets, desired weld quality, production volume, and available equipment. Each method has its own advantages and limitations.

- Q: Can steel sheets be used for manufacturing architectural elements?

- Yes, steel sheets can be used for manufacturing architectural elements. Steel sheets are commonly used in architectural applications due to their strength, durability, and versatility. They can be shaped, cut, and welded into various forms to create architectural elements such as roofs, facades, columns, and partitions. Additionally, steel sheets offer a wide range of finishes and can be painted or coated to enhance their aesthetic appeal.

Send your message to us

Hot Rolled Steel Coils Steel Sheets SS400 Good Quality

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords