Hot Rolled Steel Sheet_Plate Weight with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

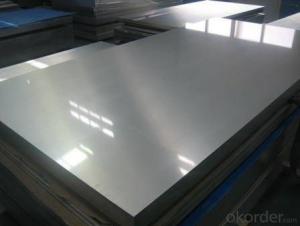

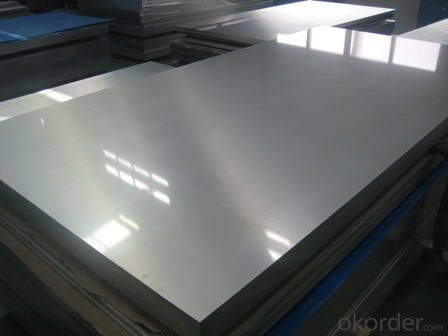

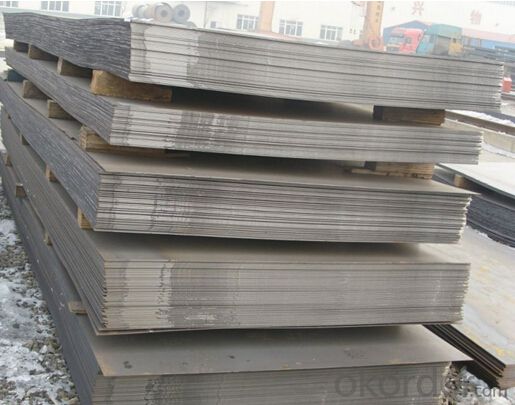

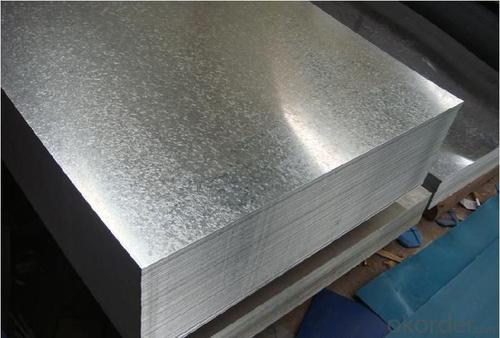

Hot Rolled Steel Sheet_Plate Weight with High Quality

Thickness:0.6-200mm

Width:1000-4000mm

MOQ: 1 ton

Certificate:ISO,SGS

Hot Rolled Steel Sheet_Plate Weight with High Quality

Commodity | Carbon Steel Hot Rolled Coil_Plate_Strip_Sheet |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | SS330, SS400, SPHC, SPHD, SPHE, Q195, Q195L, Q235, Q345, 08AL |

Usage | 1. Automobile, Bridges, Buildings,

2. Machinery, Pressure vessel industries.

3. Ship building, Engineering construction,

4. Mechanical manufacturing, Pavement slab, ect.

|

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of Hot Rolled Steel Sheet_Plate Weight with High Quality

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of Hot Rolled Steel Sheet_Plate Weight with High Quality

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different methods of surface finishing for special steel?

- There are several different methods of surface finishing for special steel, each offering unique benefits and achieving specific aesthetic or functional requirements. Some of the most commonly used methods include: 1. Electroplating: This process involves depositing a layer of metal onto the special steel surface through an electrochemical reaction. It provides enhanced corrosion resistance, improved appearance, and can also offer increased hardness or wear resistance. 2. Passivation: Passivation is a chemical treatment that removes surface contaminants and forms a thin oxide layer on the special steel. This process enhances corrosion resistance by preventing the formation of rust or other oxidation products. 3. Polishing: Polishing is a mechanical process that involves using abrasive materials to remove a thin layer of the steel surface, resulting in a smooth and shiny finish. This method is often used to improve the appearance of special steel products or to achieve a specific level of reflectivity. 4. Shot blasting: Shot blasting is a technique that involves propelling small metal beads or shots at high speed onto the special steel surface. This process removes scale, rust, or other surface contaminants, resulting in a clean and textured finish. Shot blasting is commonly used to prepare the steel for subsequent coating or painting applications. 5. Physical vapor deposition (PVD): PVD is a vacuum-based coating process that involves depositing a thin layer of material onto the special steel surface. This method offers excellent adhesion, wear resistance, and can provide various colors or finishes to enhance the aesthetics of the steel. 6. Powder coating: Powder coating involves applying a dry powder onto the special steel surface, which is then cured under heat to form a protective and decorative layer. This method offers excellent corrosion resistance, durability, and a wide range of color options. 7. Anodizing: Anodizing is an electrolytic process that creates a controlled oxide layer on the surface of certain special steel alloys. It provides increased corrosion resistance, improved appearance, and can also enhance hardness or wear resistance. These are just a few of the many methods available for surface finishing special steel. The choice of method will depend on factors such as the desired finish, functional requirements, and the specific properties of the steel being used.

- Q: How does special steel perform in stamping applications?

- Special steel performs exceptionally well in stamping applications. It is specifically designed to withstand the intense pressure and forces involved in stamping processes. Its high strength and hardness properties enable it to maintain its shape and integrity during stamping, resulting in precise and accurate formed parts. Additionally, special steel's excellent wear resistance helps prolong tool life, reducing maintenance and replacement costs. Overall, special steel is a reliable and efficient material choice for stamping applications.

- Q: What are the different pharmaceutical grades of special steel?

- There are various pharmaceutical grades of special steel that are specifically designed and produced to meet the stringent requirements of the pharmaceutical industry. These grades are used in the manufacturing of equipment, instruments, and components that come into direct contact with pharmaceutical products. The different pharmaceutical grades of special steel include: 1. 316L Stainless Steel: This grade is widely used in pharmaceutical applications due to its excellent corrosion resistance and high purity. It is often referred to as surgical stainless steel and is suitable for parts that require frequent cleaning and sterilization. 2. 304 Stainless Steel: This grade is also commonly used in the pharmaceutical industry for its corrosion resistance and ease of fabrication. It is suitable for equipment and components that do not require as frequent cleaning or sterilization. 3. Duplex Stainless Steel: This grade offers a combination of high strength and corrosion resistance, making it suitable for applications where durability and reliability are key. It is often used in pharmaceutical processing equipment that handles aggressive chemicals or high-pressure environments. 4. Hastelloy: This is a nickel-based alloy that exhibits superior resistance to corrosion, heat, and chemicals. It is commonly used in pharmaceutical applications where extreme conditions are present, such as in reactors or vessels that handle highly corrosive substances. 5. Titanium: Although not technically steel, titanium is often considered a pharmaceutical-grade material due to its excellent biocompatibility and corrosion resistance. It is used in medical implants and devices, as well as in pharmaceutical equipment that comes into contact with sensitive drugs. These pharmaceutical grades of special steel are carefully selected based on their specific properties and suitability for pharmaceutical applications. They are manufactured and tested to ensure compliance with industry standards and regulations, such as Good Manufacturing Practices (GMP) and the United States Pharmacopeia (USP). Using the appropriate grade of steel in pharmaceutical manufacturing helps to ensure product safety, quality, and integrity.

- Q: How does special steel contribute to the renewable energy aftermarket industry?

- Special steel plays a crucial role in the renewable energy aftermarket industry by enhancing the efficiency, durability, and cost-effectiveness of renewable energy systems. One of the primary applications of special steel in this industry is in the manufacturing of wind turbine components. Wind turbines require high-strength and corrosion-resistant materials to withstand the harsh environmental conditions and generate electricity efficiently. Special steel alloys, such as high-strength low-alloy (HSLA) steel and stainless steel, offer superior mechanical properties, fatigue resistance, and excellent corrosion resistance, making them ideal for wind turbine tower structures, rotor blades, and other critical components. By using special steel in wind turbine manufacturing, the renewable energy aftermarket industry can benefit from increased turbine lifespan, reduced maintenance costs, and improved energy output. The strength and durability of special steel enable taller and larger wind turbine towers, allowing for the installation of turbines in areas with lower wind speeds. This expansion of suitable locations helps to maximize the energy production potential, making wind energy a more viable and widespread renewable energy source. Furthermore, special steel also contributes to the renewable energy aftermarket industry through its application in solar power systems. Solar panels require robust mounting structures to support the weight of the panels, withstand wind and snow loads, and ensure optimal sun exposure. Special steel, with its high strength-to-weight ratio and corrosion resistance, is commonly used in these mounting structures, providing long-lasting and reliable support for solar panels. In addition to wind and solar energy, special steel finds applications in other renewable energy systems such as hydroelectric power plants and geothermal systems. These industries benefit from the corrosion resistance and resistance to extreme temperatures offered by special steel, ensuring the longevity and efficiency of the equipment. Overall, special steel significantly contributes to the renewable energy aftermarket industry by enabling the production of reliable, durable, and efficient renewable energy systems. Through its use in wind turbines, solar panels, and other renewable energy technologies, special steel helps to enhance the performance and longevity of these systems, ultimately driving the growth and adoption of renewable energy sources worldwide.

- Q: How is spring steel used in the automotive industry?

- Spring steel is used in the automotive industry primarily for manufacturing suspension systems, including coil and leaf springs. It offers excellent elasticity, durability, and resistance to deformation, allowing it to absorb shocks and provide a smoother ride. Additionally, spring steel is also utilized in various automotive components such as clamps, brackets, and fasteners due to its high strength and corrosion resistance properties.

- Q: How does special steel perform in marine applications?

- Special steel performs exceptionally well in marine applications due to its excellent corrosion resistance and high strength. The steel is specifically designed to withstand harsh marine environments, such as saltwater, which can cause corrosion and deterioration in other materials. Its resistance to corrosion ensures durability and longevity, making it an ideal choice for various marine components and structures, including ships, offshore platforms, and underwater equipment. Additionally, the high strength of special steel enhances the structural integrity and load-bearing capacity of marine applications, providing superior performance and safety in challenging conditions.

- Q: What are the properties of weathering steel?

- Weathering steel, also known as corten steel, possesses several distinctive properties. It exhibits high resistance to corrosion, making it suitable for outdoor structures without the need for protective coatings. Its unique composition allows for the formation of a stable rust-like appearance, providing an aesthetically pleasing and natural finish. Moreover, weathering steel has excellent strength and durability, making it ideal for various applications, including bridges, buildings, and architectural elements.

- Q: How does electrical steel contribute to the production of transformers and motors?

- Electrical steel, also known as silicon steel, plays a crucial role in the production of transformers and motors. Its unique magnetic properties, achieved through the addition of silicon, allow for efficient energy transfer and reduction of energy losses. The low core loss and high magnetic permeability of electrical steel enable transformers to convert high voltage electricity into lower voltage levels, and motors to efficiently convert electrical energy into mechanical motion. In essence, electrical steel is the essential material that enables the high efficiency and performance of transformers and motors, making them indispensable components in various electrical applications.

- Q: How does special steel perform in high-temperature creep resistance?

- Special steel has excellent performance in high-temperature creep resistance. It is specifically designed to withstand prolonged exposure to elevated temperatures without undergoing excessive deformation. This is achieved through the addition of alloying elements and a careful heat treatment process, which help to enhance the steel's strength, stability, and resistance to creep. Special steel's superior creep resistance makes it a reliable choice for applications that involve high temperatures and long-term stress, ensuring the structural integrity and durability of the material.

- Q: How does special steel contribute to the manufacturing of cutting blades?

- The manufacturing of cutting blades heavily relies on the use of special steel, which plays a vital role in this process. Cutting blades must possess exceptional strength, durability, and sharpness in order to effectively carry out their intended function. Special steel, also referred to as tool steel, possesses distinctive properties that make it the ideal material for the production of cutting blades. To begin with, special steel boasts remarkable hardness, allowing cutting blades to maintain their sharpness over an extended period of time. Blades made from special steel can endure the wear and tear that occurs during cutting operations. This hardness enables the blades to retain their cutting edge, resulting in a longer lifespan and enhanced cutting performance. Furthermore, special steel provides exceptional toughness, which is crucial for cutting blades. During cutting operations, blades are subjected to high impact and stress. The toughness of special steel helps to absorb these forces and prevents the blades from breaking or chipping. This ensures that the cutting blades can withstand demanding cutting tasks without compromising their performance. Additionally, special steel offers excellent corrosion resistance. Cutting blades frequently come into contact with various materials, including moisture and chemicals. The corrosion resistance of special steel prevents the blades from rusting or corroding, ensuring their longevity and reducing the need for frequent replacements. Moreover, special steel possesses good machinability, making it easier to shape and form into the desired blade design. This enhances the manufacturing process by allowing the production of cutting blades with intricate features and complex shapes. The machinability of special steel enables manufacturers to create blades with precise cutting edges and optimal geometries, resulting in superior cutting performance. In conclusion, special steel significantly contributes to the manufacturing of cutting blades by providing hardness, toughness, corrosion resistance, and good machinability. These properties ensure that cutting blades made from special steel are long-lasting, durable, and capable of delivering exceptional cutting performance in various applications.

Send your message to us

Hot Rolled Steel Sheet_Plate Weight with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords