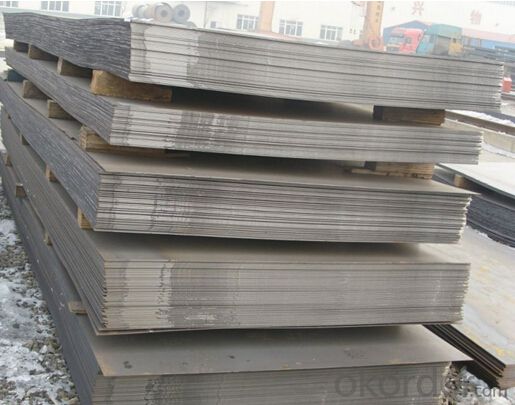

Hot Rolled Carbon Steel Plate_Sheet with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Carbon Steel Plate_Sheet High Quality

Standard | Steel Grade |

EN10025 | S235JR,S235J0,S235J2 |

DIN 17100 DIN 17102 | St33,St37-2,Ust37-2,RSt37-2,St37-3 StE255,WstE255,TstE255,EstE255 |

ASTM | A36/A36M A36 A283/A283M A283 Grade A,A283 Grade B, A283 Grade C,A283 Grade D A573/A573M A573 Grade 58,Grade 65,Grade 70 |

GB/T700 | Q235A,Q235B,Q235C,Q235D,Q235E |

JIS G3106 | SS330,SS400,SS490,SS540,SM400A,SM400B,SM400C |

Hot Rolled Carbon Steel Plate_Sheet High Quality

Product Name | Steel Grade | Thickness | Width | Application |

(mm) | (M) | |||

General structural steel | Q195,Q215A-Q,235A/B/C/D , | 1.9~25.4mm | 0.7~2 | Applied for |

Q275A/B/C/D, | normal construction | |||

SS330SS400SPHT1/2/3 | ||||

Q235CQ235D. | ||||

A36 | ||||

Low Carbon steel | SPCCSPHCSt12SAE1008 | 1.9~25.4mm | 0.7~2 | Applied for cold rolling |

SPHDSPCDKSt12St13 | 1.9~25.4mm | 0.7~2 | or cold forming | |

SPHESPCESt14 IF3 BH340 | 1.9~25.4mm | 0.7~2 | ||

Carbon constructional | 08-45#08Al15 AlS 20C S35C S45C | 1.9~25.4mm | 0.7~2 | After being machined |

Quality steel | K08AlZ06-10AlP | and hot treated to used | ||

as mechanical component | ||||

Low-alloy | SM490ASM490YA15Mn | 1.9~25.4mm | 0.7~2 | Applied for normal |

Constructional steel | Q345A/B/C/D/E | 1.9~25.4mm | 0.7~2 | construction |

Hot Rolled Steel | Q235 and customed. | 2.0mm~ 8.0mm | 0.9 | |

CNBM Introduction of the Hot Rolled Carbon Steel Plate_Sheet Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of the Hot Rolled Carbon Steel Plate_Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different methods of surface lapping for special steel?

- There are several different methods of surface lapping for special steel. These methods are used to achieve a high level of flatness and smoothness on the surface of the steel. One common method is called free abrasive lapping. In this method, a slurry containing abrasive particles is used to polish the surface of the steel. The slurry is typically applied to a rotating lap plate, which is then pressed against the steel surface. The abrasive particles remove material from the surface, resulting in a smoother and flatter surface. Another method is called fixed abrasive lapping. In this method, a rigid lap plate with abrasive particles embedded in it is used to polish the steel surface. The lap plate is typically made of a harder material than the steel being lapped. As the lap plate rotates and is pressed against the steel surface, the embedded abrasive particles remove material, resulting in a smoother surface. Chemical lapping is another method that can be used for special steel. In this method, a chemical solution is applied to the steel surface. The chemical solution reacts with the surface of the steel, dissolving and removing a thin layer of material. This method is often used when a high level of flatness is required. Ultrasonic lapping is a method that uses ultrasonic vibrations to enhance the lapping process. In this method, the steel surface is placed in contact with a bath of abrasive particles and a liquid medium. Ultrasonic vibrations are then applied to the liquid medium, causing the abrasive particles to vibrate and remove material from the surface of the steel. This method can be particularly effective for lapping hard and brittle materials. Overall, the different methods of surface lapping for special steel offer various approaches to achieve the desired level of flatness and smoothness. The selection of the method depends on factors such as the type of steel, the desired surface finish, and the specific requirements of the application.

- Q: Can special steel be used in the oil refinery industry?

- Yes, special steel can be used in the oil refinery industry. Special steel, such as stainless steel or high alloy steel, is often preferred in the oil refinery industry due to its superior corrosion resistance and high temperature strength. It is commonly used in various applications, including piping, tanks, heat exchangers, and valves, to ensure durability and reliability in the harsh and corrosive environment of oil refineries.

- Q: What are the factors that affect the fatigue strength of special steel?

- There are several factors that can affect the fatigue strength of special steel. These include the composition and microstructure of the steel, the presence of defects or impurities, the surface finish and treatment, the loading conditions and stress levels, and the temperature and environmental conditions in which the steel operates. Additionally, factors such as heat treatment, alloying elements, and manufacturing processes can also impact the fatigue strength of special steel.

- Q: How does special steel perform in medical applications?

- Special steel, which is also referred to as stainless steel, has established itself as a material of great versatility and reliability for various medical applications. Its distinct properties render it an optimal choice for medical instruments, devices, and equipment. Above all, special steel exhibits a high level of corrosion resistance, a crucial characteristic in medical settings where exposure to moisture and the need for sterilization are common occurrences. This resistance enables the steel to maintain its durability and prevents any degradation over time, making it suitable for prolonged use. Furthermore, special steel is biocompatible, meaning it does not elicit any negative reactions when in contact with living tissues or bodily fluids. This biocompatibility is of utmost importance for medical implants like prosthetics, orthopedic screws, and dental implants, as it minimizes the risk of rejection or infection. Moreover, special steel offers exceptional strength and hardness, enabling it to withstand the demanding conditions encountered during medical procedures. It can retain its structural integrity even when subjected to extreme temperatures or high-pressure environments, making it ideal for surgical instruments and cutting tools. Its hardness also facilitates the creation of sharp and precise cutting edges, ensuring the accuracy and effectiveness of surgical procedures. Additionally, special steel boasts a smooth surface finish, which renders it easy to clean and sterilize. This attribute is of paramount importance in medical applications where maintaining a sterile environment is crucial to prevent the spread of infections. The smooth surface also hinders the accumulation of bacteria or other contaminants, thereby reducing the risk of contamination. In conclusion, special steel has undeniably proven itself as a highly reliable and versatile material for medical applications. Its corrosion resistance, biocompatibility, strength, and ease of sterilization make it an ideal choice for medical instruments, devices, and implants. The exceptional performance of special steel in medical applications significantly contributes to improving patient care, ensuring safety, and enhancing the overall effectiveness of medical procedures.

- Q: What are the main factors affecting the creep resistance of special steel?

- The main factors affecting the creep resistance of special steel are the alloy composition, the microstructure, and the processing conditions. The specific combination of alloying elements and their concentrations significantly influence the material's ability to resist deformation under elevated temperatures and constant stress. Additionally, the microstructure, including grain size and distribution, plays a crucial role in determining the material's creep resistance. The processing conditions, such as heat treatment and thermal cycling, can further affect the creep performance by altering the material's microstructure and mechanical properties.

- Q: What are the main applications of special steel in the telecommunications sector?

- Special steel is widely used in the telecommunications sector for various applications. One of the main uses is in the manufacturing of transmission towers and antennas, where high strength and corrosion resistance properties are crucial for ensuring stability and durability. Special steel is also utilized in the production of cables and wires, providing excellent conductivity and resistance to wear and tear. Additionally, special steel is employed in the fabrication of satellite communication equipment, providing the necessary strength and resilience to withstand harsh environmental conditions. Overall, special steel plays a vital role in the telecommunications sector by enabling the construction of reliable and high-performance infrastructure.

- Q: What are the advantages of using special steel?

- There are several advantages of using special steel. Firstly, special steel offers enhanced strength and durability compared to regular steel, making it suitable for applications that require high resistance to wear, fatigue, and impact. Secondly, special steel has excellent heat resistance, allowing it to maintain its structural integrity even at high temperatures. Additionally, special steel can be tailored to meet specific requirements, such as corrosion resistance, electrical conductivity, or magnetic properties. This versatility makes it suitable for a wide range of industries, including automotive, aerospace, construction, and energy. Overall, the advantages of using special steel include superior strength, durability, heat resistance, and customization possibilities.

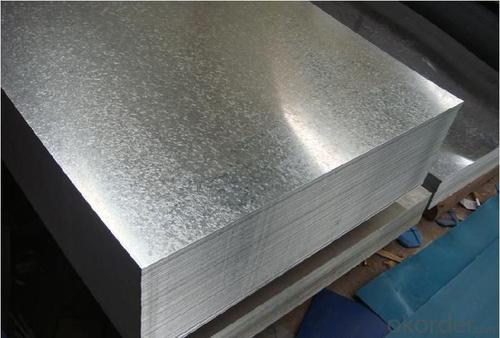

- Q: What are the different coating options available for special steel?

- Some of the different coating options available for special steel include galvanizing, powder coating, electroplating, and organic coatings such as epoxy or polyurethane. These coatings provide protection against corrosion, enhance durability, and improve the aesthetics of the steel.

- Q: What is the impact of carburizing on the properties of special steel?

- The process known as carburizing, or case hardening, is utilized to introduce carbon into the surface layer of special steel, resulting in several beneficial effects. Firstly, carburizing forms a tough outer layer, called the case, which is carbon-rich. The infusion of carbon atoms into the steel matrix during carburizing increases the carbon content on the surface, leading to a higher level of hardness compared to the core. This hardened case provides exceptional resistance against wear, abrasion, and surface fatigue, making it ideal for applications requiring high durability, such as gears, camshafts, and bearings. Moreover, carburizing enhances the strength of the steel by improving its ability to form martensite, a hard, crystalline structure. This transformation contributes further to the hardness and strength of the carburized steel, making it suitable for applications necessitating high load-bearing capacity, like shafts and axles. Furthermore, carburizing has the potential to improve the fatigue resistance of special steel. The hardened case created during the carburizing process helps distribute stress evenly across the surface, reducing the probability of crack initiation and propagation. This enhanced resistance to fatigue failure makes carburized steel appropriate for components exposed to cyclic loading, such as gears and springs. However, it is important to acknowledge that carburizing also has its drawbacks. The higher carbon content on the surface can reduce the material's ductility and toughness, making it more susceptible to brittle fracture. To address this issue, it is common practice to utilize steel with a lower carbon content for the core, ensuring a balance between hardness and toughness. In conclusion, carburizing significantly impacts the properties of special steel, enhancing hardness, wear resistance, and strength, which is advantageous for applications requiring durability, high load-bearing capacity, and fatigue resistance. Nevertheless, careful control of the process is necessary to maintain a balance between hardness and toughness, ensuring the overall performance and reliability of the material.

- Q: What are the different annealing techniques used for special steel?

- Some of the different annealing techniques used for special steel include full annealing, process annealing, spheroidizing annealing, and stress relieving annealing. Full annealing involves heating the steel to a temperature above its critical point and then slowly cooling it to room temperature. Process annealing is used to improve the machinability of the steel by heating it to a lower temperature and then cooling it in a controlled manner. Spheroidizing annealing is used to soften the steel and improve its ductility by heating it to a temperature just below its critical point and then cooling it slowly. Stress relieving annealing is used to reduce internal stress in the steel by heating it to a temperature below its critical point and then cooling it slowly.

Send your message to us

Hot Rolled Carbon Steel Plate_Sheet with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords