Hot Rolled Steel Sheets With Good Price And Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

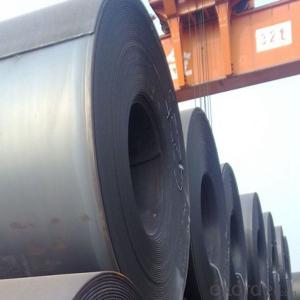

DETAILED PICTURES FOR STEEL COILS

EXPORT MARKET FOR STEEL COILS/SHEETS

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

OUR SERVICE

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: Can steel sheets be used for signage or advertising boards?

- Yes, steel sheets can be used for signage or advertising boards. Steel is a durable and weather-resistant material, making it suitable for outdoor applications. It can be easily cut, shaped, and painted to create custom designs for signage or advertising purposes. Additionally, steel's strength allows for larger and more robust signboards, ensuring visibility and longevity.

- Q: Are steel sheets suitable for agricultural machinery or equipment?

- Yes, steel sheets are commonly used in agricultural machinery and equipment due to their high strength, durability, and resistance to harsh outdoor conditions.

- Q: What is the average lifespan of steel sheets used for roofing?

- The lifespan of steel sheets used for roofing can vary based on several factors. Nevertheless, high-quality steel roofing sheets are designed to be extremely durable and long-lasting. On average, these steel sheets can endure for 40 to 70 years or potentially even longer if properly maintained and cared for. The longevity of steel roofing sheets can be influenced by factors such as the steel type and thickness, the coating or finish quality, the climate and weather conditions in the area, and the level of maintenance. Conducting regular inspections, cleaning, and repairs as necessary can help extend the lifespan of the steel sheets and ensure their good condition for many years. It is always advisable to seek guidance from roofing professionals or manufacturers for specific guidelines and recommendations regarding the lifespan of steel sheets used for roofing in a particular context.

- Q: Can steel sheets be used for garage doors?

- Yes, steel sheets can be used for garage doors. They are commonly used due to their durability, strength, and resistance to weather conditions.

- Q: How do steel sheets perform in magnetic properties?

- Steel sheets have low magnetic permeability, which means they are not strongly attracted to magnets and do not retain magnetism after being magnetized.

- Q: How do steel sheets perform in terms of dimensional stability?

- Steel sheets are known for their excellent dimensional stability. This means that they are highly resistant to changes in size or shape when subjected to external forces or fluctuations in temperature. Steel is inherently strong and rigid, allowing it to maintain its shape and dimensions over extended periods of time. Additionally, steel sheets have low thermal expansion coefficients, meaning they expand and contract minimally with changes in temperature. This characteristic further enhances their dimensional stability, making them suitable for applications where precise dimensions and consistent performance are critical. Steel sheets are widely used in various industries, including construction, automotive, and manufacturing, due to their reliable dimensional stability.

- Q: What is the lifespan of steel sheets?

- The lifespan of steel sheets can vary depending on various factors such as the quality of the steel, the environment it is exposed to, and the level of maintenance. However, on average, steel sheets can last for several decades or even up to a century if properly maintained.

- Q: Can steel sheets be used for heat exchangers?

- Yes, steel sheets can be used for heat exchangers. Steel is a common material used in heat exchangers due to its excellent thermal conductivity and durability. However, the specific type of steel and its composition may vary depending on the application and desired performance of the heat exchanger.

- Q: Are steel sheets suitable for manufacturing elevator doors?

- Yes, steel sheets are suitable for manufacturing elevator doors. Steel is a popular choice for elevator doors due to its strength, durability, and aesthetic appeal. Steel sheets offer the necessary strength and rigidity required for elevator doors, ensuring safety and security. Additionally, steel is resistant to wear and tear, corrosion, and fire, making it a reliable material for elevator doors. Steel sheets can also be easily customized and finished to meet various design requirements, allowing for a wide range of styles and finishes. Overall, steel sheets provide the necessary qualities for manufacturing elevator doors, making them a suitable choice for this application.

- Q: What is the average wind load capacity of steel sheets?

- The average wind load capacity of steel sheets can vary depending on various factors such as sheet thickness, size, shape, and the specific steel material used. It is typically determined by conducting engineering calculations and considering local building codes and standards. Therefore, it is not possible to provide a specific average wind load capacity without knowing the specific details of the steel sheets in question.

Send your message to us

Hot Rolled Steel Sheets With Good Price And Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords