Hot Rolled Steel I-Beam with best quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

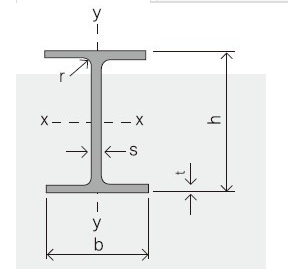

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What is the normal tolerance of your steel products ?

A3: Normally 7%-9%, but we can also produce the goods according to the customers' requests.

Images:

- Q: What is the purpose of a camber in a steel I-beam?

- The purpose of a camber in a steel I-beam is to counteract the natural deflection that occurs when the beam is loaded, ensuring that it remains straight and level under the anticipated load.

- Q: How do you calculate the torsional deflection of a steel I-beam?

- To calculate the torsional deflection of a steel I-beam, you need to consider various factors and apply relevant formulas. Here is a step-by-step guide to calculate the torsional deflection: 1. Gather the necessary information: Start by collecting the required data, including the dimensions of the I-beam, such as its height (h), width of the flanges (b1 and b2), thickness of the flanges (t1 and t2), and the length of the beam (L). 2. Determine the material properties: Identify the properties of the steel being used, especially the modulus of rigidity (G) or shear modulus. This value represents the material's resistance to shear deformation and is necessary for the calculations. 3. Calculate the cross-sectional area: Determine the cross-sectional area of the I-beam by subtracting the area of two rectangles (flanges) from the area of one rectangle (web). The area of the web can be calculated as A = h * (b1 - t1 - t2) + b2 * t2. 4. Determine the polar moment of inertia: The polar moment of inertia (J) represents a beam's resistance to torsional deformation. It can be calculated using various formulas depending on the shape of the cross-section. For an I-beam, the formula is J = (b1 * t1^3 + b2 * t2^3) / 3. 5. Calculate the maximum shear stress: The maximum shear stress (τ) caused by torsional loading can be calculated using the formula τ = T * r / J, where T is the applied torque and r is the distance from the center of the beam to the outermost point on the cross-section. 6. Determine the torsional deflection: The torsional deflection (θ) can be calculated using the formula θ = T * L / (G * J), where T is the applied torque, L is the length of the beam, G is the shear modulus, and J is the polar moment of inertia. By following these steps and plugging in the appropriate values, you can calculate the torsional deflection of a steel I-beam. It is important to note that these calculations provide an approximation and should be verified by a professional engineer to ensure accuracy and safety.

- Q: Can steel I-beams be used in performing arts venues or theaters?

- Yes, steel I-beams can be used in performing arts venues or theaters. They are commonly utilized for structural support in large venues due to their strength, durability, and ability to span long distances. Steel I-beams provide a stable framework for rigging equipment, lighting, and sound systems, ensuring the safety and functionality of the space.

- Q: Can steel I-beams be used in hospitals or healthcare facilities?

- Yes, steel I-beams can be used in hospitals or healthcare facilities. Steel I-beams are commonly used in the construction industry due to their strength, durability, and load-bearing capacity. In healthcare facilities, where the safety and integrity of the structure are crucial, steel I-beams can provide the necessary support for the building. They are often used in the construction of floors, walls, and roofs, ensuring the stability of the overall structure. Additionally, steel I-beams are resistant to fire, pests, and weathering, making them a reliable choice for healthcare facilities that require a long-lasting and low-maintenance construction solution.

- Q: How do steel I-beams contribute to the overall stability and strength of a structure?

- Steel I-beams contribute to the overall stability and strength of a structure in several ways. Firstly, their unique shape, which resembles the letter "I," provides exceptional resistance to bending forces. This means that I-beams are capable of supporting heavy loads and distributing them evenly across their length, minimizing the risk of sagging or collapsing. Moreover, the use of steel as the material for I-beams adds to their strength. Steel is known for its high tensile strength, meaning it can resist stretching or breaking under heavy loads. This attribute allows I-beams to withstand significant pressure without deforming or failing, ensuring the structural integrity of the entire building. Additionally, the design of I-beams allows for efficient use of materials. The top and bottom flanges of the beam are wider and thicker than the vertical web in the center. This configuration maximizes the beam's resistance to bending forces while minimizing the weight of the overall structure. The lightweight nature of steel I-beams makes them easier to handle during construction, reducing costs and labor requirements. Furthermore, the versatility of steel I-beams contributes to the overall stability of a structure. Engineers can adjust the size and shape of the beams according to the specific requirements of the building, ensuring optimal performance and load-bearing capacity. This flexibility allows for the creation of complex architectural designs while maintaining structural integrity. In summary, steel I-beams provide significant contributions to the overall stability and strength of a structure. Their unique shape, high tensile strength, efficient material usage, and versatility make them an indispensable component in modern construction, enabling buildings to withstand heavy loads and ensure the safety of their occupants.

- Q: Can steel I-beams be used for railway or bridge construction?

- Certainly, railway or bridge construction can utilize steel I-beams. Their utilization in such applications is commonplace owing to their robustness and endurance. These beams possess the capability to bear substantial loads and furnish the essential structural integrity that railway tracks and bridges necessitate. Moreover, steel I-beams exhibit resistance to corrosion, rendering them suitable for enduring outdoor conditions. Furthermore, their adaptability permits the implementation of diverse designs and configurations tailored to meet specific engineering prerequisites. In summary, steel I-beams consistently prove to be a prevalent and dependable option for railway and bridge construction endeavors.

- Q: Are steel I-beams suitable for supporting rooftop swimming pools?

- Steel I-beams are indeed an appropriate choice for supporting rooftop swimming pools. These beams are widely used in construction due to their robustness and ability to bear heavy loads. They have been specifically designed to withstand substantial weight and offer exceptional structural support. In the case of rooftop swimming pools, the water, pool equipment, and additional features like decking and furniture can add up to a significant amount of weight. Steel I-beams are capable of evenly and effectively distributing this weight, thereby ensuring the stability and safety of the rooftop pool. Moreover, steel I-beams possess durability, resistance to corrosion, and the flexibility to be tailored to meet specific design requirements. Consequently, they represent a dependable and suitable option for supporting rooftop swimming pools.

- Q: Can steel I-beams be used in railway bridge construction?

- Certainly, railway bridge construction can make use of steel I-beams. These I-beams have become a popular choice in bridge construction because of their exceptional strength, durability, and capability to bear heavy loads. They are extensively employed in both highway and railway bridge construction ventures. Steel I-beams deliver the essential strength and stability required to sustain the weight of trains and the dynamic loads they generate during operation. Moreover, steel possesses advantages such as resistance to corrosion and flexibility in design, rendering it a viable option for railway bridge construction. In summary, steel I-beams are a dependable and efficient option for constructing railway bridges.

- Q: What are the standard sizes of steel I-beams?

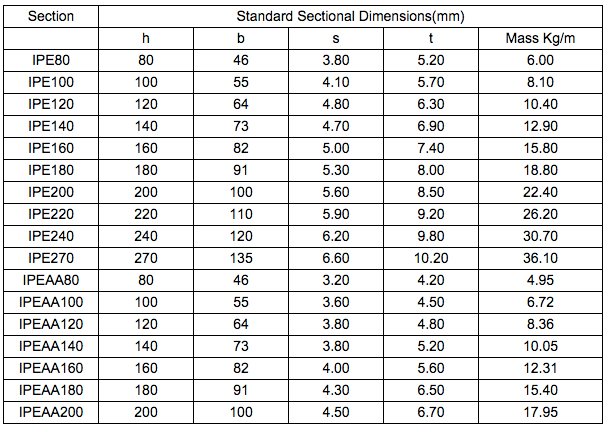

- Different organizations and industry standards dictate the standard sizes of steel I-beams, resulting in variations. Nonetheless, there are commonly used sizes prevalent in construction and structural engineering. The American Institute of Steel Construction (AISC) in the United States offers a comprehensive list of standard sizes for steel I-beams. These sizes encompass a range from S3x5.7 to S24x121, incorporating different dimensions such as depth, flange width, and weight per foot. Similarly, the European I-beam (IPE) sizes, recognized worldwide, adhere to another standard. IPE sizes span from IPE80 to IPE750, featuring diverse measurements for depth, flange width, and weight per meter. Apart from these American and European standards, individual countries might establish their own standard sizes for steel I-beams. It is crucial to consult relevant national or international standards when selecting the appropriate size for a specific application. It is worth noting that the sizes mentioned are merely a few examples of standard sizes, and availability may vary based on the manufacturer and location. It is always advisable to seek advice from an engineer or professional in the field to determine the most suitable size for a particular project or design requirement.

- Q: How are steel I-beams protected against corrosion?

- Steel I-beams are protected against corrosion through various methods, such as galvanization, painting, or applying protective coatings. Galvanization involves coating the steel with a layer of zinc, which acts as a sacrificial barrier, preventing corrosion from reaching the steel. Painting involves applying a layer of paint that acts as a barrier against moisture and oxygen, preventing corrosion. Additionally, protective coatings can be applied to steel I-beams, which provide an extra layer of protection against corrosion. These methods help to prolong the lifespan and integrity of steel I-beams in various applications.

Send your message to us

Hot Rolled Steel I-Beam with best quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords