Hot Rolled H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Hot Rolled H-Beam Steel

1. Standard: JIS G3101

2. Grade: SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

SIZE(mm) | DIMENSION(kg/m) |

100*100 | 16.9 |

125*125 | 23.6 |

150*75 | 14 |

150*150 | 31.1 |

148*100 | 20.7 |

198*99 | 17.8 |

200*100 | 20.9 |

248*124 | 25.1 |

250*125 | 29 |

300*150 | 36.7 |

298*149 | 32 |

200*200 | 49.9 |

294*200 | 55.8 |

346*174 | 41.2 |

350*175 | 49.4 |

244*175 | 43.6 |

175*175 | 40.4 |

294*200 | 55.8 |

298*201 | 64.4 |

346*174 | 41.2 |

350*175 | 49.4 |

400*200 | 65.4 |

396*199 | 56.1 |

450*200 | 74.9 |

446*199 | 65.1 |

340*250 | 78.1 |

500*200 | 88.1 |

300*150 | 36.7 |

Usage & Applications of Hot Rolled H-Beam Steel

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled H-Beam Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

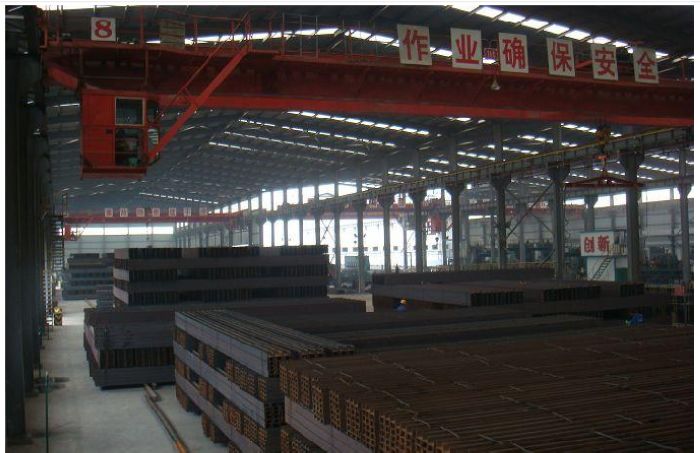

Production flow of Hot Rolled H-Beam Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How do steel H-beams contribute to the overall sustainability of a structure?

- There are several ways in which the use of steel H-beams enhances the overall sustainability of a structure. To begin with, steel is an incredibly resilient material that can withstand harsh weather conditions, seismic activities, and fire, ensuring the enduring safety of the structure. This durability eliminates the need for frequent repairs or replacements, reducing resource consumption and waste generation. Moreover, steel H-beams possess a lightweight quality, unlike materials such as concrete or wood, thereby decreasing the overall weight of the structure. This lightweight characteristic facilitates more efficient transportation and construction processes, resulting in reduced energy consumption and carbon emissions during construction. Additionally, steel H-beams are highly recyclable, making them an ideal sustainable choice. At the end of a building's life cycle, these beams can be easily dismantled and transformed into new steel products without compromising their inherent properties. By recycling steel, the demand for new materials is diminished, conserving energy and decreasing greenhouse gas emissions associated with the production of fresh steel. Furthermore, steel H-beams offer design flexibility, enabling architects and engineers to create innovative and efficient structures. Their versatility allows for optimal material usage, minimizing waste and maximizing resource utilization. Moreover, this adaptability facilitates future modifications or expansions of the structure without extensive demolition or reconstruction. Lastly, steel H-beams possess a high strength-to-weight ratio, meaning they can support larger loads with less material. This efficiency in material usage reduces the overall environmental impact of the structure, as less steel is required to achieve the same structural integrity. Consequently, the use of steel H-beams in construction contributes to resource conservation and minimizes the carbon footprint of the building. In conclusion, the utilization of steel H-beams in construction enhances the overall sustainability of a structure due to their durability, lightweight nature, recyclability, design flexibility, and efficient material usage. By opting for steel H-beams, we can construct buildings that are not only safe and long-lasting but also environmentally friendly, conserving resources and reducing the carbon footprint of the construction industry.

- Q: How do Steel H-Beams compare in terms of lifespan and durability?

- Steel H-Beams are known for their exceptional lifespan and durability. These structural members are specifically designed to withstand heavy loads and provide long-lasting support for various construction projects. The lifespan of steel H-Beams can be significantly longer compared to other building materials such as wood or concrete. One of the key factors contributing to their durability is the inherent strength of steel. H-Beams are made from high-quality steel, which has superior tensile strength and resistance to bending and twisting forces. This enables them to withstand extreme weather conditions, seismic activity, and other external factors that can cause damage to structures over time. Moreover, steel H-Beams are not susceptible to rot, decay, or insect infestations like wooden beams. They also do not degrade or weaken under moisture, which is a common issue with concrete structures. This makes steel H-Beams highly durable and reliable, ensuring their long-term performance and structural integrity. Additionally, steel H-Beams are resistant to fire, which further enhances their lifespan and durability. Steel has a high melting point and does not contribute fuel to a fire, making it a safer choice for structural elements. This characteristic is particularly important in high-rise buildings or structures where fire protection is a critical consideration. Furthermore, steel H-Beams can be easily inspected for any signs of wear or damage. Regular maintenance and inspections can help identify and address any issues promptly, ensuring the continued durability and longevity of these structural members. In conclusion, steel H-Beams have a remarkable lifespan and durability due to their high strength, resistance to environmental factors, and fire resistance. These qualities make them an excellent choice for a wide range of construction projects where longevity and structural integrity are paramount.

- Q: Are steel H-beams fire-resistant?

- Yes, steel H-beams are fire-resistant. Steel is an inherently fire-resistant material due to its high melting point and low flammability. H-beams, being made of steel, can withstand high temperatures and retain their structural integrity during a fire.

- Q: What is the average cost of steel H-beams?

- The price of steel H-beams can differ depending on different factors like their size, weight, and quality. Typically, the cost of steel H-beams ranges from $500 to $2000 per ton. Nevertheless, it is crucial to bear in mind that these prices may change due to fluctuations in the market and the rates set by each supplier. Furthermore, the quantity and location of the purchase can also impact the final price. Thus, it is advisable to consult multiple suppliers and compare prices in order to obtain a more precise estimate for the average cost of steel H-beams.

- Q: What are the different welding methods for steel H-beams?

- There are several different welding methods that can be used for steel H-beams. 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW is a common method used for welding H-beams. It involves using a consumable electrode coated in flux, which creates a shield around the weld pool to protect it from contaminants and oxidation. This method is versatile and can be used for welding in various positions and environments. 2. Gas Metal Arc Welding (GMAW): Also known as MIG welding, GMAW uses a continuous solid wire electrode and a shielding gas. This method offers high deposition rates, good weld quality, and can be easily automated. It is commonly used for H-beam welding in fabrication shops. 3. Flux-Cored Arc Welding (FCAW): FCAW is similar to GMAW but uses a tubular electrode filled with flux instead of a solid wire. The flux provides shielding and also contains deoxidizers and other elements to enhance the weld quality. FCAW is known for its high deposition rates and can be used for both indoor and outdoor welding applications. 4. Submerged Arc Welding (SAW): SAW is a highly efficient method that involves feeding a continuous wire electrode into a weld joint while a granular flux is poured over it. The flux covers the weld and prevents atmospheric contamination. SAW is commonly used for heavy-duty applications, such as welding large steel H-beams. 5. Laser Beam Welding (LBW): LBW is a precise and high-energy welding method that uses a focused laser beam to create a weld. It is commonly used for thin steel H-beams and offers excellent control and minimal distortion. However, LBW requires specialized equipment and is typically used in industrial settings. These are just a few of the many welding methods available for steel H-beams. The choice of method depends on factors such as the thickness of the material, desired weld quality, production speed, and available equipment. It is important to select the appropriate welding method based on the specific requirements of the H-beam project.

- Q: Can steel H-beams be used in the construction of residential complexes or apartments?

- Steel H-beams are indeed applicable for the construction of residential complexes or apartments. These structural components are known for their strength and versatility, making them a common choice in construction projects. Compared to materials like wood or concrete, steel H-beams offer several advantages. To begin with, steel H-beams possess a high strength-to-weight ratio, enabling them to bear heavy loads while remaining relatively lightweight. This characteristic makes them ideal for the construction of large or multi-story buildings such as residential complexes or apartments. Furthermore, steel H-beams exhibit exceptional durability and resistance to various environmental factors, including earthquakes, hurricanes, and termites. Their high tensile strength allows them to endure significant forces and deformations without breaking. Moreover, steel H-beams can be easily customized to meet specific design requirements. They can be effortlessly cut, welded, and bolted together, facilitating flexible construction designs. A notable aspect of steel is its sustainability and eco-friendliness. It can be recycled indefinitely without compromising its innate properties, making it an environmentally responsible choice for construction projects. In conclusion, steel H-beams offer a multitude of advantages that render them suitable for the construction of residential complexes and apartments. Their strength, durability, versatility, and sustainability make them a favored option among architects and builders in the construction industry.

- Q: Can steel H-beams be used for agricultural structures?

- Yes, steel H-beams can be used for agricultural structures. Steel H-beams provide excellent structural support and can be used for various agricultural applications such as barns, warehouses, and equipment storage buildings. They offer high strength and durability, making them suitable for withstanding heavy loads and adverse weather conditions. Additionally, steel H-beams are versatile and can be easily customized to meet specific requirements, making them a popular choice for agricultural construction.

- Q: Can steel H-beams be used in retrofitting existing structures?

- Yes, steel H-beams can be used in retrofitting existing structures. Steel H-beams are commonly used in structural engineering and construction projects due to their strength and versatility. When retrofitting an existing structure, steel H-beams can be used to reinforce or replace weak or damaged load-bearing components such as columns, beams, or floor systems. This allows for the existing structure to be strengthened and brought up to current building codes and standards. Steel H-beams can also be used to add additional support or create new structural elements, such as mezzanine floors or roof extensions, in the retrofitting process. Overall, steel H-beams are a reliable and effective choice for retrofitting existing structures.

- Q: Can steel H-beams be used in residential balcony or terrace structures?

- Residential balcony or terrace structures can indeed utilize steel H-beams. The strength and durability of steel H-beams make them a popular choice for construction projects. They offer exceptional structural support and can handle heavy loads, making them ideal for supporting balconies and terraces. Moreover, steel H-beams can be tailored and designed to fulfill specific architectural and engineering requirements, ensuring a secure and safe structure. Nevertheless, it is imperative to seek guidance from a qualified structural engineer or architect to determine the appropriate size and design of the steel H-beams for the specific residential balcony or terrace structure. This consultation should take into account factors such as load-bearing capacity, local building codes, and environmental conditions.

- Q: Are steel H-beams suitable for use in the construction of water treatment plants or facilities?

- Yes, steel H-beams are suitable for use in the construction of water treatment plants or facilities. Steel H-beams are known for their strength, durability, and load-bearing capacity, making them ideal for supporting heavy structures in water treatment plants. Additionally, steel is resistant to corrosion, which is crucial in a water treatment environment where exposure to moisture and chemicals is common. Overall, steel H-beams provide a reliable and long-lasting structural solution for water treatment facilities.

Send your message to us

Hot Rolled H Beam

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords