Japanese Standard SS400 H beam with High Quality 482mm-600mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

1. Standard: JIS 3192

2. Grade: SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Size and Mass of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

| Size(mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 482*300*11.0 | 111 | 596*199*10.0 | 92.5 |

| 488*300*11.0 | 125 | 600*200*11.0 | 103 |

Packaging & Delivery of Japanese Standard SS400 H beam with High Quality 482mm-600mm for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel.

Usage of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

(1). for the plant, high-rise building construction

(2). for the bridge, shipment building

(3).for lifting and transportation machinery, equipment manufacturing base building

(4). for the support, foundation pile manufacturing

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 months from the beginning of production.

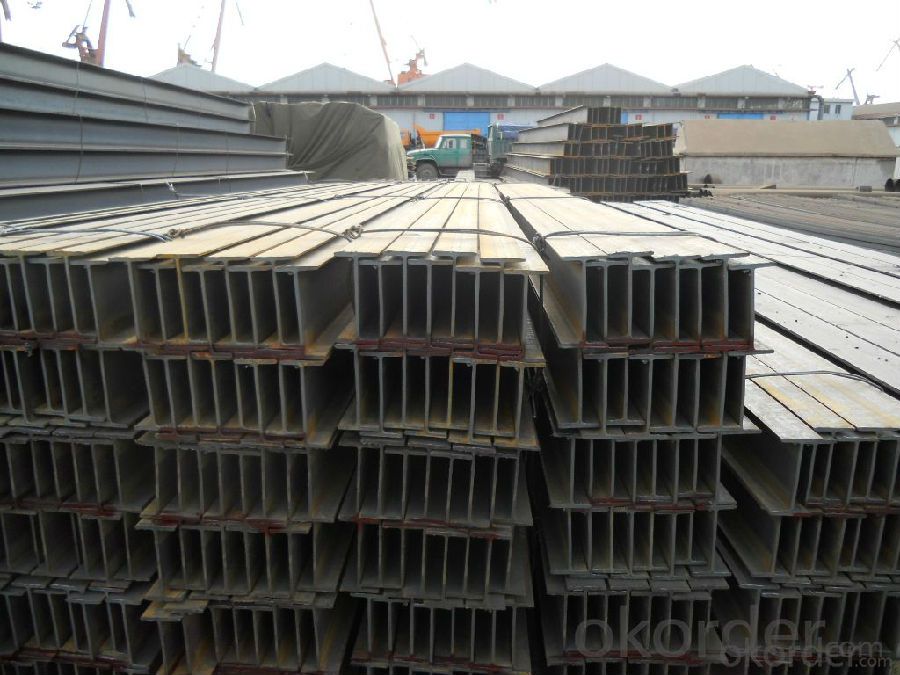

Images of Japanese Standard SS400 H beam with High Quality 482mm-600mm:

* If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Are steel H-beams suitable for industrial structures?

- Yes, steel H-beams are highly suitable for industrial structures. H-beams, also known as I-beams or universal beams, are specifically designed to carry heavy loads and provide structural stability. Their shape, with a wider flange and narrower web, allows them to distribute weight evenly and resist bending or twisting forces. Steel H-beams have several advantages that make them ideal for industrial structures. Firstly, they have a high strength-to-weight ratio, meaning they can support heavy loads while being relatively lightweight, which makes them cost-effective and easier to handle during construction. Additionally, steel is a strong and durable material that can withstand harsh environmental conditions and resist corrosion, ensuring the longevity and safety of the structure. Another advantage of steel H-beams is their versatility. They can be easily fabricated to different lengths and sizes, allowing for flexible design options and accommodating various construction requirements. Moreover, H-beams can be bolted or welded together to create larger structural components, making them suitable for constructing wide-span industrial buildings or supporting heavy machinery and equipment. Furthermore, steel H-beams offer excellent structural integrity and stability. Their shape provides resistance against bending and torsion, making them suitable for withstanding dynamic loads and seismic forces. This makes them particularly suitable for industrial structures that are exposed to heavy machinery operations, vibrations, or potential impacts. In conclusion, steel H-beams are highly suitable for industrial structures due to their strength, durability, versatility, and stability. They provide efficient load-bearing capabilities, allowing for the construction of strong and reliable industrial buildings that can withstand heavy loads and harsh environmental conditions.

- Q: Can steel H-beams be used for roof support?

- Yes, steel H-beams can be used for roof support. H-beams, also known as I-beams, are structural steel beams with an H-shaped cross-section. They are widely used in construction and engineering due to their high strength and load-bearing capacity. When it comes to roof support, steel H-beams provide excellent structural support and stability. They are often used in commercial and industrial buildings where large spans and heavy loads are common. The H-shaped design of these beams allows them to distribute the weight evenly across the beam's flanges and web, making them suitable for supporting the weight of a roof. Additionally, steel H-beams can be easily connected and welded together to create a solid and durable roof support system.

- Q: What are the factors that affect the cost of steel H-beams?

- There are several factors that can affect the cost of steel H-beams: 1. Raw material costs: The cost of the raw materials used to manufacture steel H-beams, such as iron ore and coal, can have a significant impact on the overall cost. Fluctuations in the prices of these materials, influenced by factors like supply and demand, can directly affect the cost of producing steel H-beams. 2. Manufacturing process: The method used to manufacture steel H-beams can also impact their cost. Different manufacturing processes, such as hot-rolling or cold-forming, require varying levels of energy, labor, and equipment, which can affect the overall cost. 3. Size and weight: The size and weight of the steel H-beams can impact the cost. Larger and heavier beams require more raw material and may require additional handling and transportation costs, which can increase the overall price. 4. Market demand: The demand for steel H-beams can also affect their cost. If there is a high demand for these beams, prices may increase due to limited supply. Conversely, if the demand is low, prices may be lower as manufacturers compete for customers. 5. Trade policies and international market conditions: Trade policies and international market conditions can also impact the cost of steel H-beams. Factors such as tariffs, import restrictions, and currency exchange rates can affect the cost of raw materials and the overall cost of production, which in turn can impact the final price of the beams. 6. Manufacturing location: The geographical location of the manufacturing facility can also play a role in the cost of steel H-beams. Different regions may have varying labor costs, energy costs, and transportation costs, all of which can affect the final price of the beams. 7. Quality and specifications: The quality and specifications of the steel H-beams can also influence their cost. Higher quality beams that meet stricter standards and specifications may command a higher price compared to lower quality beams. Overall, the cost of steel H-beams is influenced by various factors, including raw material costs, manufacturing process, size and weight, market demand, trade policies, manufacturing location, and quality and specifications. Understanding these factors can help buyers and sellers make informed decisions and negotiate prices effectively.

- Q: How do steel H-beams perform in high humidity environments?

- Steel H-beams generally perform well in high humidity environments. The steel used in H-beams is typically coated with protective finishes, such as galvanization or epoxy coatings, which help prevent corrosion caused by moisture. However, prolonged exposure to high humidity and saltwater environments can still lead to rusting and degradation over time. Regular maintenance and inspections are recommended to ensure their long-term performance.

- Q: How do you calculate the maximum shear stress in steel H-beams?

- To calculate the maximum shear stress in steel H-beams, you need to determine the shear force acting on the beam and the cross-sectional properties of the beam. The formula for calculating shear stress in a beam is: Shear Stress = (Shear Force * Distance from Neutral Axis) / (Area of Cross Section) First, you need to calculate the shear force acting on the beam. This can be done by analyzing the external loads and support conditions. For example, if the H-beam is subjected to a uniform distributed load, you would calculate the shear force by multiplying the magnitude of the load by the length of the beam. Next, you need to determine the distance from the neutral axis to the point of interest. The neutral axis is the axis that passes through the centroid of the cross-section and is perpendicular to the applied shear force. The distance can be measured from the centroid to the top or bottom edge of the beam, depending on the location of the point where you want to calculate the shear stress. Finally, you need to determine the area of the cross-section of the H-beam. This can be done by dividing the cross-section into different shapes (e.g., rectangles, triangles) and calculating the area of each shape separately. Once you have the areas of all the individual shapes, you can add them up to get the total cross-sectional area. Once you have the shear force, the distance from the neutral axis, and the area of the cross-section, you can plug these values into the formula to calculate the maximum shear stress. Keep in mind that the maximum shear stress occurs at the point farthest from the neutral axis, which is usually at the top or bottom flange of the H-beam. It is important to note that when calculating the maximum shear stress in steel H-beams, you should also consider any additional factors such as bending moments, torsion, and any other relevant load combinations that may affect the beam's structural integrity.

- Q: Can steel H-beams be used in the construction of residential complexes or apartments?

- Yes, steel H-beams can be used in the construction of residential complexes or apartments. Steel H-beams are strong and versatile structural components that are commonly used in construction projects. They offer several advantages over other materials such as wood or concrete. Firstly, steel H-beams have a high strength-to-weight ratio, which means they can support heavy loads while being relatively lightweight themselves. This makes them ideal for constructing large or multi-story buildings like residential complexes or apartments. Secondly, steel H-beams provide excellent durability and resistance to various environmental factors such as earthquakes, hurricanes, and termites. They have high tensile strength, which means they can withstand significant forces and deformations without breaking. Moreover, steel H-beams are highly customizable and can be fabricated to meet specific design requirements. They can be easily cut, welded, and bolted together, allowing for flexible construction designs. Additionally, steel is a sustainable and eco-friendly material. It can be recycled indefinitely without losing its inherent properties, making it an environmentally responsible choice for construction projects. In summary, steel H-beams offer numerous advantages that make them suitable for the construction of residential complexes and apartments. Their strength, durability, versatility, and sustainability make them a popular choice among architects and builders in the construction industry.

- Q: Are steel H-beams resistant to corrosion?

- Yes, steel H-beams are resistant to corrosion due to their protective coating or galvanization process, which helps prevent rusting and extends their lifespan.

- Q: Can steel H-beams be used for agricultural storage buildings?

- Agricultural storage buildings can indeed utilize steel H-beams. These beams are widely employed in construction due to their durability and strength. They offer exceptional support and load-bearing capabilities, making them an ideal choice for storing heavy agricultural products, machinery, or equipment. Moreover, steel H-beams possess resistance against pests, fire, and adverse weather conditions, rendering them a reliable option for agricultural storage buildings. Nevertheless, it is crucial to consider various factors such as building size, design, local building codes, and specific requirements for the storage facility. Consulting a structural engineer or construction professional can ensure that the steel H-beams align with the precise needs and demands of the agricultural storage structure.

- Q: What are the common fire protection measures for steel H-beams?

- Steel H-beams can be protected from fire through the use of various measures. One common method involves applying fire-resistant coatings directly onto the beams. These coatings are designed to endure high temperatures, effectively preventing the steel from reaching its critical temperature and thus maintaining its structural integrity. Another option is to use intumescent paints, which expand when exposed to heat. This expansion creates an insulating layer that slows down the transfer of heat to the steel beam, safeguarding it from the destructive effects of fire. Additionally, fire-resistant cladding can be installed around the steel H-beams. This cladding acts as an extra protective layer, insulating the steel from heat and flames. By implementing these measures, the structural stability of steel H-beams can be ensured during a fire, preventing any potential failure.

- Q: What are the different sizes and dimensions of steel H-beams?

- Steel H-beams come in various sizes and dimensions to meet different construction and engineering needs. The sizes and dimensions of steel H-beams are typically categorized by their depth (height), flange width, and weight per foot. The depth of an H-beam refers to the vertical distance from the top to the bottom flange. Common depths for steel H-beams range from 4 inches to 24 inches, with increments of 2 inches. However, deeper depths may also be available for specialized applications. The flange width of an H-beam is the horizontal width of the top and bottom flanges. Standard flange widths can range from 4 inches to 12 inches, with increments of 1 inch. Like the depth, wider flange widths may be available for specific requirements. The weight per foot of an H-beam is an important dimension that determines the load-bearing capacity. It is measured in pounds per linear foot (plf) and varies depending on the size and dimensions of the H-beam. The weight per foot can range from 17 plf to 300 plf or more, depending on the specific H-beam size. It is important to note that the sizes and dimensions of steel H-beams can vary across different countries and regions. For example, the American Society for Testing and Materials (ASTM) standardizes H-beam sizes in the United States, while the European Norm (EN) standardizes them in Europe. These standards may have slight variations in sizes and dimensions. In summary, steel H-beams come in various sizes and dimensions, with variations in depth, flange width, and weight per foot. These variations allow for the selection of the most suitable H-beam for specific construction or engineering applications.

Send your message to us

Japanese Standard SS400 H beam with High Quality 482mm-600mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords