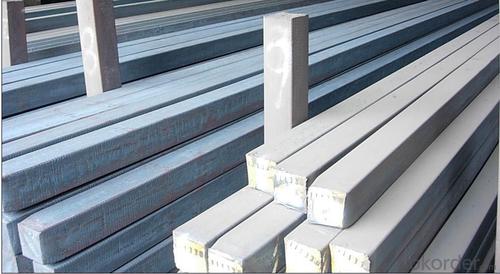

Hot Rolled Steel Billet 3SP Standard 150mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Steel Billet 3SP Standard 150mm

Description of Hot Rolled Steel Billet 3SP Standard 150mm

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Main Feature of Hot Rolled Steel Billet 3SP Standard 150mm

1.Corrosion resistance: It mainly depends on the zinc protection. When the zinc being worn,

2. Heat resistance: steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Applications of Hot Rolled Steel Billet 3SP Standard 150mm

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;road sign; etc.

4.Agriculture constructions :barn; etc.RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

5.Others:vending machine; game machine; auto parts spare parts etc.

Specifications of Hot Rolled Steel Billet 3SP Standard 150mm

Product | Hot Rolled Steel Billet 3SP Standard 150mm |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.5-3.0mm |

Width | 700-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled,RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Hot Rolled Steel Billet 3SP Standard 150mm

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 100 mt for each size each specification. Usually we can offer discount if can buy large QTY once. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

2. How long can we receive the product after ordering?

Our general delivery time is 30 days after confirmation, but so some special orders, we have offer special delivery time

3. How to guarantee the quality of the products?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What is the payment?

We accept T/T, L/C

- Q: How are steel billets used in the manufacturing of valves and fittings?

- Steel billets are used in the manufacturing of valves and fittings as the starting material. These billets are heated and then mechanically or forge pressed to shape them into the desired valve or fitting component. The billets provide the necessary strength and durability required for these critical components in various industries.

- Q: How do steel billets contribute to the manufacturing of furniture?

- The manufacturing of furniture relies heavily on steel billets, which serve as the essential raw material needed to create strong and durable frames. These billets, produced through casting or hot rolling, are semi-finished steel products with a rectangular shape. After obtaining the steel billets, they can undergo various manufacturing techniques such as forging, extrusion, or machining to shape them into different furniture components. These components include frames for chairs, tables, beds, and other elements that require stability and strength. Using steel billets in furniture manufacturing offers several advantages. Firstly, steel is renowned for its exceptional strength and durability, making it an ideal material for furniture that can handle heavy loads and regular use. By utilizing steel billets, the furniture becomes robust and long-lasting, reducing the need for frequent replacements. In addition, steel billets provide design flexibility as they can be easily molded and shaped into different forms. This allows furniture manufacturers to create intricate and unique designs that meet customers' aesthetic preferences. Moreover, steel billets can be seamlessly welded, resulting in a more cohesive and visually appealing final product. Furthermore, steel is highly resistant to corrosion, which is crucial for furniture that may be exposed to moisture or environmental factors. By incorporating steel billets, the furniture remains free from corrosion, preserving its appearance and structural integrity over time. In conclusion, steel billets are indispensable in furniture manufacturing as they provide the necessary strength, durability, and flexibility to create sturdy frames and structural components. Their utilization enables furniture manufacturers to produce high-quality products that are long-lasting, visually appealing, and resistant to corrosion.

- Q: What are the different surface treatments for improved weldability in steel billets?

- There are several surface treatments that can be used to improve weldability in steel billets. These include processes such as pickling, grinding, and shot blasting. Pickling involves removing any surface impurities or oxides through the use of acid solutions. Grinding helps to smooth out any rough or uneven surfaces, ensuring better contact and fusion during the welding process. Shot blasting uses high-speed projectiles to clean the surface and create a rough texture, which enhances the adhesion of the weld. These treatments help to remove contaminants and improve the overall quality and weldability of the steel billets.

- Q: What are the common sizes of steel billets used in construction?

- The common sizes of steel billets used in construction can vary depending on the specific project and requirements. However, there are several standard sizes that are commonly used in the construction industry. These sizes typically range from 100 mm (4 inches) to 200 mm (8 inches) in width and 100 mm (4 inches) to 300 mm (12 inches) in height. The length of the billets can also vary, but they are often around 6 meters (20 feet) long. These standard sizes are widely available and easily accessible, making them a popular choice for construction projects. However, it is important to note that the actual sizes of steel billets used in construction can be customized based on the specific needs and engineering requirements of a particular project.

- Q: How do steel billets contribute to the overall aesthetics of a structure?

- Steel billets, which are semi-finished steel products, do not directly contribute to the overall aesthetics of a structure. However, they play a crucial role in the manufacturing process of various steel components such as beams, columns, and decorative elements. These components, when properly designed and incorporated into a structure, can enhance its aesthetic appeal by providing strength, durability, and architectural uniqueness.

- Q: What are the different surface treatments for improved formability in steel billets?

- To enhance the formability of steel billets, various surface treatments can be employed. These treatments aim to increase the steel's ability to be shaped and formed without experiencing cracks or fractures. One effective method for enhancing formability is the utilization of lubricants or coatings. These substances aid in reducing friction between the steel and the forming tools, facilitating the shaping of the billets without causing any damage. Lubricants can be administered in the form of oils, greases, or solid films, and they can be utilized in both hot and cold forming procedures. Another technique for improving formability is shot peening, which entails bombarding the steel's surface with small steel or ceramic particles that possess high velocity. This process creates a compressive stress layer on the surface, effectively preventing crack initiation and propagation during the forming process. Additionally, shot peening can enhance the steel's fatigue resistance. In certain instances, heat treatment can be employed to enhance formability. This involves heating the steel to a specific temperature and rapidly cooling it. This process, known as quenching and tempering, can modify the steel's microstructure, increasing its ductility and making it easier to shape. Heat treatment also aids in relieving residual stresses in the steel, thereby improving formability. Lastly, surface coatings can be applied to steel billets to enhance formability. These coatings act as a protective barrier between the steel and the forming tools, reducing friction and preventing wear. Various methods, such as electroplating, thermal spraying, or chemical vapor deposition, can be utilized to apply these coatings. In conclusion, there exist several surface treatments that can be employed to enhance formability in steel billets. These treatments encompass the application of lubricants or coatings, shot peening, heat treatment, and surface coatings. Each treatment offers unique advantages and can be utilized based on the specific requirements of the forming process.

- Q: What are the potential applications of steel billets in the mining aftermarket?

- Steel billets possess a wide range of potential applications within the mining aftermarket. The manufacturing of heavy machinery and equipment utilized in mining operations represents one of the primary uses for steel billets. These components, including gears, shafts, and cylinders, necessitate high strength and durability to withstand the harsh conditions inherent in mining activities. Moreover, steel billets can also be employed in the creation of wear-resistant parts for mining equipment, such as cutting edges, buckets, and liners. Given the intense wear and tear endured by these parts, the use of steel billets guarantees their longevity and dependability. Additionally, steel billets find use in the construction of mine support structures, such as beams, columns, and frames. These structures play a crucial role in ensuring the stability and safety of mining operations, and steel billets provide the requisite strength and load-bearing capacity for their construction. Furthermore, steel billets can be utilized in the production of tools and accessories essential for mining activities. Drill bits, hammers, and chisels, for instance, demand high strength and toughness to effectively penetrate hard rock formations. Steel billets serve as the ideal material for fabricating these tools. In summary, the potential applications of steel billets within the mining aftermarket are extensive and encompass various aspects of mining operations. Ranging from the manufacturing of heavy machinery and equipment to the production of wear-resistant parts and mine support structures, steel billets provide the necessary strength, durability, and reliability required to optimize mining processes.

- Q: What are the potential defects or flaws in steel billets?

- There are several potential defects or flaws that can occur in steel billets, which can affect the quality and performance of the final product. Some of these defects include: 1. Surface defects: Steel billets can develop surface cracks, scales, or scratches during the manufacturing process. These defects can weaken the material and reduce its structural integrity. 2. Internal defects: Inclusions, such as non-metallic impurities or gas bubbles, can be present within the steel billets. These internal defects can cause localized weaknesses and reduce the overall strength of the material. 3. Segregation: Uneven distribution of alloying elements or impurities can lead to segregation, where certain areas of the billet have different chemical compositions. Segregation can result in inconsistent mechanical properties across the material and decrease its uniformity. 4. Central segregation: This defect occurs when there is a concentration of impurities or alloying elements in the central region of the billet, leading to a weaker core. Central segregation can cause structural failures and reduce the overall reliability of the steel billet. 5. Shrinkage cavities: During the solidification process, shrinkage cavities can form in the steel billet due to the contraction of the molten metal. These cavities can weaken the material and compromise its structural integrity. 6. Surface decarburization: Exposure to high temperatures or improper heat treatment can cause the surface of the steel billet to lose carbon content, resulting in surface decarburization. This defect can reduce the hardness and strength of the material. 7. Laminations: Laminations are thin, elongated voids or layers that can form parallel to the surface of the billet. These defects can weaken the material and make it prone to cracking or failure under stress. 8. Internal cracks: Internal cracks can occur due to improper cooling or handling of the billet during the manufacturing process. These cracks can compromise the structural integrity of the steel billet and potentially lead to catastrophic failure. It is important to detect and address these defects early on to ensure the quality and reliability of the steel billets. Various non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, can be utilized to identify and mitigate these potential flaws.

- Q: What are the different methods used for heating steel billets?

- Heating steel billets can be achieved through various methods, each tailored to meet specific application requirements and constraints. Some commonly employed techniques include: 1. Induction Heating: By passing an alternating current through a coil, electromagnetic induction generates a magnetic field that induces electrical currents in the billet, subsequently producing heat. This method provides precise and controllable heating, ensuring uniformity throughout the billet. 2. Gas Furnaces: Utilizing burners, gas furnaces generate heat that is then transferred to the steel billets via convection. Commonly fueled by natural gas or propane, these furnaces offer flexibility in terms of temperature control, heating rate, and energy efficiency. 3. Electric Resistance Heating: This method involves passing electric current through resistive elements, such as heating elements or heating pads, in direct contact with the steel billets. The resistance to the electric current generates heat, which is then transferred to the billets. Electric resistance heating is typically used for smaller-scale operations or applications with specific heating requirements. 4. Flame Heating: Flame heating employs an open flame, usually produced by a gas burner, to heat the steel billets. The billets absorb the radiant heat emitted by the flame, resulting in heating. Flame heating is commonly utilized for larger billets or applications that necessitate rapid heating. 5. High-Frequency Heating: Through the use of electromagnetic fields, high-frequency heating achieves billet heating. The billets are positioned within a coil, and a high-frequency alternating current is passed through the coil, generating electrical currents in the billets. Heat is produced as a result of the resistance to these electrical currents, ensuring rapid and uniform heating. 6. Laser Heating: High-powered lasers are employed in laser heating to heat the steel billets. The laser beam is focused on the billet's surface, allowing for intense heat generation through the absorption of laser energy. Laser heating provides precise and localized heating, making it suitable for specific applications or for heat treating small areas of the billets. These aforementioned methods represent only a fraction of the techniques commonly employed for heating steel billets. The choice of method depends on various factors, including the required heating rate, temperature control, energy efficiency, and the specific characteristics of the billets.

- Q: How do steel billets contribute to the manufacturing of telecommunications equipment?

- Steel billets play a crucial role in the manufacturing of telecommunications equipment by providing the necessary raw material for various components and structures. These billets, typically made from carbon steel, are semi-finished products that are further processed to create specific shapes and sizes required for telecommunications equipment. One of the key ways steel billets contribute to the manufacturing of telecommunications equipment is by serving as the base material for the fabrication of towers and masts. These structures are vital for the installation of antennas and satellite dishes, enabling the transmission and reception of signals for telecommunications networks. Steel billets are shaped and welded to create sturdy and durable towers that can withstand various environmental conditions. Moreover, steel billets are also used in the production of enclosures and cabinets for housing telecommunication equipment. These enclosures provide protection from external factors such as dust, moisture, and vandalism, ensuring the proper functioning and longevity of the equipment. Steel billets are formed into panels, frames, and chassis that are then assembled to create robust enclosures that can withstand harsh environments. In addition, steel billets contribute to the manufacturing of telecommunications equipment by being used in the production of cable trays and supports. These components are essential for organizing and routing cables, providing a neat and efficient infrastructure for telecommunications systems. Steel billets are rolled and formed into various shapes, such as channels and angles, to create sturdy cable trays and supports that can handle the weight and stress of multiple cables. Furthermore, steel billets are also utilized in the fabrication of connectors and brackets for telecommunications equipment. These small yet crucial components provide the necessary connections and support for different devices and modules in telecommunications systems. Steel billets are machined, drilled, and shaped into specific designs to create reliable connectors and brackets that ensure proper functionality and stability. Overall, steel billets play a vital role in the manufacturing of telecommunications equipment by providing the necessary raw material for various components and structures. Their strength, durability, and versatility make them an ideal choice for creating robust and reliable equipment that can withstand the demands of modern communication networks.

Send your message to us

Hot Rolled Steel Billet 3SP Standard 150mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords