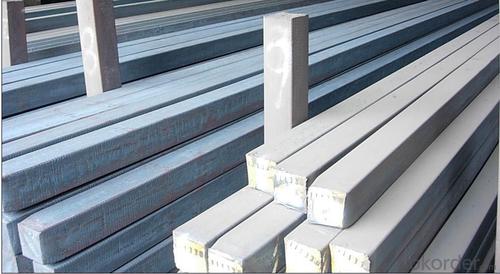

Hot Rolled Steel Billet 3SP Standard 155mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Steel Billet 3SP Standard 155mm

Description of Hot Rolled Steel Billet 3SP Standard 155mm

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Main Feature of Hot Rolled Steel Billet 3SP Standard 155mm

1.Corrosion resistance: It mainly depends on the zinc protection. When the zinc being worn,

2. Heat resistance: steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

Applications of Hot Rolled Steel Billet 3SP Standard 155mm

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; gas tank;road sign; etc.

4.Agriculture constructions :barn; etc.RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

5.Others:vending machine; game machine; auto parts spare parts etc.

Specifications of Hot Rolled Steel Billet 3SP Standard 155mm

Product | Hot Rolled Steel Billet 3SP Standard 155mm |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.5-3.0mm |

Width | 700-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled,RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Hot Rolled Steel Billet 3SP Standard 155mm

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 100 mt for each size each specification. Usually we can offer discount if can buy large QTY once. RAL Scale Z35 Prepainted Rolled Steel Coil for Construction Roofing

2. How long can we receive the product after ordering?

Our general delivery time is 30 days after confirmation, but so some special orders, we have offer special delivery time

3. How to guarantee the quality of the products?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What is the payment?

We accept T/T, L/C

- Q: Are steel billets used in the manufacturing of construction machinery?

- Steel billets are a common choice for the manufacturing of construction machinery. They serve as semi-finished products, acting as raw materials across various industries, including construction machinery manufacturing. To create these billets, molten steel is cast into a solid form and then undergoes additional shaping and sizing processes. The high strength, durability, and versatility of steel billets make them well-suited for constructing robust components and structures in construction machinery. Examples of parts that can be manufactured using steel billets include chassis, frames, buckets, booms, and arms, among others. By utilizing steel billets, construction machinery becomes capable of withstanding the demanding conditions and heavy loads commonly encountered in construction projects.

- Q: What are the main alloying elements used in steel billet production?

- The main alloying elements used in steel billet production are carbon, manganese, silicon, and chromium.

- Q: What is the purpose of using steel billets in the manufacturing industry?

- The purpose of using steel billets in the manufacturing industry is primarily to serve as a raw material for further processing and shaping into various steel products. Steel billets are semi-finished metal products that are cast in a specific shape and size, typically in a square or rectangular cross-section. These billets provide a consistent and standardized starting point for the production of a wide range of steel products, such as bars, rods, wire, tubes, pipes, and structural components. By using steel billets, manufacturers can ensure uniformity in the material properties and dimensions of their end products, which is crucial for maintaining quality and meeting industry standards. Moreover, steel billets offer several advantages in terms of their strength, durability, and versatility. Steel is known for its exceptional strength-to-weight ratio, making it an ideal choice for applications that require high structural integrity and load-bearing capacity. The use of steel billets allows manufacturers to produce components that can withstand heavy loads, extreme temperatures, and harsh environmental conditions. Furthermore, steel billets can be easily shaped and processed through various techniques such as rolling, forging, extrusion, and machining. This flexibility enables manufacturers to create a wide range of steel products with different shapes, sizes, and properties, catering to diverse industrial needs. Overall, the purpose of using steel billets in the manufacturing industry is to provide a reliable and versatile raw material for producing high-quality steel products that serve various applications in construction, automotive, aerospace, machinery, infrastructure, and many other sectors.

- Q: What are the different surface defects in steel billets?

- There are several different types of surface defects that can be found in steel billets. These defects can occur during the manufacturing process or as a result of handling and transportation. Some common surface defects in steel billets include: 1. Scale: Scale is a thin layer of oxide that forms on the surface of steel billets during the heating and rolling process. It appears as a rough, flaky coating and can negatively affect the surface quality and appearance of the billet. 2. Cracks: Cracks can occur on the surface of steel billets due to various reasons such as improper cooling, excessive rolling pressure, or high levels of stress during handling. These cracks can range from minor surface cracks to more severe deep cracks, compromising the integrity and strength of the billet. 3. Lamination: Lamination defects occur when there are layers or sheets of non-metallic inclusions within the steel billet. These layers can cause weak spots in the billet, making it susceptible to failure under stress. 4. Pitting: Pitting is the formation of small, localized cavities or depressions on the surface of the steel billet. It can be caused by various factors such as corrosion, improper cleaning, or exposure to corrosive environments. 5. Slivers: Slivers are thin, elongated pieces of steel that protrude from the surface of the billet. They can be caused by improper cutting or shearing operations, which can result in sharp edges and potential safety hazards. 6. Rolled-in scale: Rolled-in scale refers to the presence of scale that has been embedded into the surface of the billet during the rolling process. This can affect the surface finish and may require additional cleaning or surface treatment. 7. Surface scratches: Surface scratches are shallow marks or abrasions on the surface of the steel billet. They can occur during handling, transportation, or as a result of contact with abrasive surfaces. While they may not significantly impact the structural properties of the billet, they can affect the aesthetics and may require further treatment or polishing. It is important to identify and address these surface defects in steel billets to ensure the quality and performance of the final product. Regular inspection, proper handling, and appropriate surface treatment techniques can help minimize these defects and improve the overall quality of the steel billets.

- Q: Can steel billets be cold rolled?

- No, steel billets cannot be cold rolled. Cold rolling is a process that involves reducing the thickness of a metal sheet or strip by passing it through a series of rollers at room temperature. However, steel billets are primarily used as raw material for the production of steel bars, rods, and other long products through a process known as hot rolling. In this process, the steel billets are heated to high temperatures and then passed through a series of rolling mills to achieve the desired shape and dimensions. Cold rolling is not suitable for steel billets as it requires heating to make the steel more malleable and easily deformable, which is not possible with the solid, unheated billets.

- Q: What is the typical weight of a steel billet?

- The weight of a steel billet can differ based on its size and purpose, resulting in a range of common weights between 1,000 and 5,000 pounds (450 to 2,270 kilograms). This weight range grants flexibility in manufacturing processes and enables diverse applications across industries like construction, automotive, and manufacturing. It is crucial to acknowledge that distinct weight prerequisites might vary according to the steel billet's intended use and specifications.

- Q: What are the different methods of steel billet surface cleaning?

- Steel billet surface cleaning can be achieved through various methods, each with its own set of advantages and disadvantages. Some commonly used methods include: 1. Shot Blasting: By propelling small metallic or non-metallic particles at high speeds onto the billet surface, rust, scale, and other contaminants are effectively removed. Shot blasting is a quick and efficient method for cleaning large surfaces. However, it may result in surface roughness and may not be suitable for all types of steel. 2. Acid Pickling: This method involves immersing the steel billet in an acid solution, typically hydrochloric or sulfuric acid, to eliminate scale and rust. The acid reacts with the surface contaminants, dissolving them and leaving a clean surface. Acid pickling is particularly effective in removing stubborn scale and rust. However, it requires careful handling of corrosive acids and proper waste disposal. 3. Mechanical Cleaning: Mechanical cleaning methods utilize abrasive tools or brushes to physically scrub the billet surface. This can be done manually or with the assistance of machinery. Mechanical cleaning effectively removes loose contaminants and scale. However, it may not be suitable for heavily rusted or firmly adhered contaminants. 4. High-Pressure Water Jetting: This method employs high-pressure water jets to cleanse the billet surface. The force of the water effectively removes scale, rust, and other contaminants. High-pressure water jetting is environmentally friendly as it does not involve the use of chemicals. However, it may not be as effective in removing heavy scale or rust. 5. Ultrasonic Cleaning: Ultrasonic cleaning entails immersing the steel billet in a tank filled with a cleaning solution and subjecting it to high-frequency ultrasonic vibrations. These vibrations generate tiny bubbles in the cleaning solution, which collapse on the billet surface, effectively eliminating contaminants. Ultrasonic cleaning is highly efficient in removing even microscopic particles and can reach complex geometries. However, it may not be suitable for large-scale cleaning operations. Each method possesses its own unique strengths and limitations. The selection of a specific method depends on factors such as the type and condition of the surface contaminants, time and cost constraints, and the desired surface finish.

- Q: How are steel billets used in the production of shafts?

- Steel billets are used in the production of shafts by being heated and then forged or machined into the desired shape and size. The billets serve as the raw material from which the shafts are formed, providing the necessary strength and durability required for various applications such as automotive, machinery, and construction industries.

- Q: How do steel billets compare to other steel products?

- Steel billets are raw steel products that are formed into a specific shape, typically a square or rectangular cross-section. They are often used as a starting material for further processing and manufacturing of various steel products. Compared to other steel products, steel billets offer flexibility in terms of size and shape, allowing manufacturers to produce a wide range of end products. Additionally, steel billets possess superior strength and durability, making them an excellent choice for structural and construction applications.

- Q: What is the role of steel billets in the manufacturing of automotive body panels?

- Steel billets play a crucial role in the manufacturing of automotive body panels as they are the starting material for the production process. These billets are heated, shaped, and formed into various body panel components, such as doors, hoods, and fenders. Their high strength and durability make them ideal for providing structural integrity and protection in automotive applications. Additionally, the malleability of steel billets allows for intricate designs and shaping, ensuring precise and smooth body panel surfaces.

Send your message to us

Hot Rolled Steel Billet 3SP Standard 155mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords