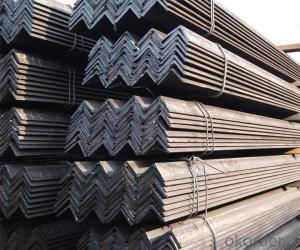

Hot Rolled Steel Bar Equal Bar Unequal Bar SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Bar Equal Bar Unequal Bar SS400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Bar Equal Bar Unequal Bar SS400 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Bar Equal Bar Unequal Bar SS400 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

Images:

- Q: Can steel angles be used for signposts and traffic signals?

- Yes, steel angles can be used for signposts and traffic signals as they provide strength and stability required for supporting these structures.

- Q: What are the considerations for selecting the appropriate steel angle connection type?

- When selecting the appropriate steel angle connection type, several considerations need to be taken into account to ensure the structural integrity and stability of the connection. 1. Load capacity: The connection type should be capable of withstanding the anticipated loads, including the dead load, live load, wind load, and seismic load. The connection should be designed to transfer these loads efficiently without causing any failure or compromise in the overall structure. 2. Structural requirements: The connection type should meet the specific structural requirements of the project, such as the desired level of stiffness, flexibility, or rigidity. This includes considering factors like the connection's ability to resist deflection or movement under different loading conditions. 3. Safety and reliability: The connection type should be chosen with a focus on safety and reliability. It should be able to provide a secure and durable connection that will not fail or deteriorate over time. Factors such as the material properties, corrosion resistance, and maintenance requirements should be considered to ensure the long-term performance of the connection. 4. Cost-effectiveness: The selected connection type should be cost-effective in terms of material and labor requirements. It should balance the project's budget constraints while still meeting the necessary performance standards. Considering factors such as ease of fabrication, installation, and maintenance can help in determining the most cost-effective connection type. 5. Compatibility and availability: The connection type should be compatible with the existing steel members and components to ensure a proper fit and integration. It should also be readily available in the market to avoid any delays or supply chain issues during construction. 6. Design and construction constraints: Any specific design or construction constraints, such as space limitations, access restrictions, or architectural requirements, should be considered when selecting the connection type. It should be chosen in a way that accommodates these constraints without compromising the overall structural integrity. 7. Code and regulatory compliance: The selected connection type should comply with the applicable building codes, standards, and regulations. It is essential to ensure that the connection design and construction meet all the necessary requirements to guarantee the safety and legal compliance of the structure. By carefully considering these factors, engineers and designers can select the appropriate steel angle connection type that best meets the project's requirements in terms of load capacity, structural integrity, safety, cost-effectiveness, and compliance with codes and regulations.

- Q: How do you maintain and clean steel angles?

- To maintain and clean steel angles, you can start by removing any dirt or debris using a mild soap and water solution. Avoid using abrasive cleaners or tools that can scratch the surface of the steel. After cleaning, it is important to thoroughly dry the angles to prevent any water spots or rust formation. Applying a protective coating or wax can also help maintain their appearance and prevent corrosion. Regular inspections and prompt removal of any rust spots or stains will ensure the longevity of the steel angles.

- Q: Are steel angles susceptible to fatigue failure?

- Yes, steel angles can be susceptible to fatigue failure. Fatigue failure occurs when a material undergoes repeated loading and unloading cycles, leading to the initiation and propagation of cracks within the material. Steel angles, like any other structural components, can be subject to cyclic loading conditions, such as vibrations, oscillations, or repeated stress applications. Fatigue failure in steel angles is influenced by various factors, including the material's properties, the geometric shape of the angle, the magnitude and frequency of the applied loads, and the presence of any defects or stress concentrations. The presence of notches, welds, or sharp corners can act as stress raisers, leading to localized stress concentrations and potential crack initiation sites. To mitigate the risk of fatigue failure, engineers and designers consider several strategies. Firstly, understanding the anticipated loading conditions and designing the structure with appropriate safety factors can help ensure that the steel angles are not subjected to stress levels that exceed their fatigue strength. Secondly, minimizing stress concentrations through proper design, such as using rounded corners or fillets, can help distribute the stress more uniformly and reduce the likelihood of crack initiation. Additionally, regular inspection and maintenance of structures can help identify any potential fatigue cracks and allow for necessary repairs or replacements.

- Q: Are steel angles available in non-standard dimensions?

- Steel angles in non-standard dimensions can be obtained. Although standard steel angles are typically manufactured in specific sizes, such as 2x2 inches or 3x3 inches, there are manufacturers and suppliers capable of producing steel angles in custom sizes to fulfill specific project requirements. These custom sizes may involve varying leg lengths, thicknesses, or overall dimensions that are not commonly found in standard steel angles. Achieving the desired dimensions can be accomplished through processes like cutting, bending, and welding when fabricating custom steel angles. Nevertheless, it is important to consider that non-standard dimensions may result in additional time and cost for production compared to readily available standard sizes.

- Q: Can steel angles be used in mining or offshore applications?

- Yes, steel angles can be used in mining or offshore applications. Steel angles are commonly used in these industries due to their strength, durability, and versatility. They can be used for various purposes such as framing, support, reinforcement, and bracing in mining structures and offshore platforms. Additionally, steel angles can withstand harsh environments, extreme weather conditions, and corrosive elements commonly found in mining or offshore operations. Their ability to provide structural stability and resistance to impact and vibrations makes them suitable for these applications. Overall, steel angles are a reliable and cost-effective choice for mining and offshore industries.

- Q: How do you specify steel angles in a construction project?

- In a construction project, steel angles are typically specified by indicating the dimensions of the angle and the type of steel used. This includes specifying the length and width of the angle, as well as the thickness of the steel. Additionally, the type of steel, such as A36 or A572, may be specified to ensure the desired strength and durability.

- Q: Are steel angles suitable for supporting heavy machinery?

- Indeed, steel angles possess the necessary attributes to effectively support heavy machinery. Boasting strength, durability, and an elevated load-bearing capacity, these angles emerge as a prime selection for bolstering heavy machinery. Their prevalence in both industrial settings and construction ventures is a testament to their ability to furnish structural support. By either employing bolts or welding techniques, one can seamlessly amalgamate these angles, yielding a robust framework capable of withstanding the weight and vibrations engendered by heavy machinery. Moreover, the versatility of steel angles permits customization, facilitating the development of resilient and dependable support structures tailored to meet specific requirements posed by heavy machinery.

- Q: Can steel angles be used in oil and gas pipeline installations?

- Yes, steel angles can be used in oil and gas pipeline installations. Steel angles are commonly used as structural supports in various industries, including the oil and gas sector. They provide strength and stability to pipeline installations, helping to ensure the integrity and safety of the infrastructure. Steel angles are known for their high strength-to-weight ratio, corrosion resistance, and durability, which make them suitable for demanding environments such as oil and gas pipelines. Additionally, steel angles can be easily welded or bolted together, allowing for efficient and cost-effective installation. Overall, steel angles are a reliable and commonly used component in oil and gas pipeline installations.

- Q: What size does angle iron 125*10 mean?

- The sides are 125*125*10MM thick and the theoretical weight is 19.133 per meter

Send your message to us

Hot Rolled Steel Bar Equal Bar Unequal Bar SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords