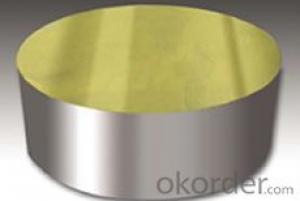

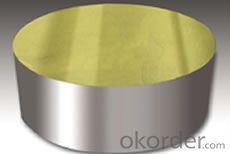

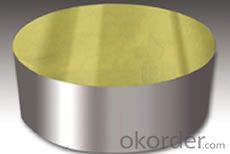

Spring Steel Round Bar Hot Rolled

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Spring Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

For manufacturing all kinds of flat spring or round spring with small sections, clockwork spring,

Product Advantages:

OKorder's Spring Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

-Material: 70Si2CrA

-Production: Hot rolled or cold rolled

-Standard: GB/T·5218-1999

-Type: Spring Steel

-Alloy or no: Alloy

Chemical Composition:

C | Mn | Si | Cr |

0.65~0.75 | 0.40~0.60 | 1.40~1.70 | 0.20~0.40 |

S | P | Ni | |

≤0.030 | ≤0.030 | ≤0.030 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How is special steel used in the defense manufacturing process?

- Special steel is commonly used in the defense manufacturing process due to its exceptional strength, durability, and resistance to extreme conditions. It is utilized in the production of various defense equipment and components such as armored vehicles, submarines, aircraft carriers, and ballistic missiles. Special steel is crucial for enhancing the overall performance, reliability, and safety of these defense systems, making it an essential material in the defense manufacturing industry.

- Q: What are the corrosion resistance properties of special steel?

- Special steels are known for their excellent corrosion resistance properties. These steels have specific alloying elements added to enhance their resistance to corrosion, making them highly resistant to rust and various corrosive environments. Their composition and surface treatment provide a protective barrier against chemical reactions, moisture, and other corrosive agents, ensuring their durability and longevity in various applications.

- Q: Can special steel be used in the chemical processing industry?

- Yes, special steel can be used in the chemical processing industry. Special steel alloys are specifically designed to withstand the harsh conditions of chemical processing, including exposure to corrosive chemicals, high temperatures, and pressure. These steels have excellent resistance to corrosion and can maintain their mechanical properties even in extreme environments. Therefore, they are commonly utilized in the construction of chemical reactors, pipelines, storage tanks, and various other equipment used in the chemical processing industry.

- Q: What are the machining techniques for special steel?

- Some of the machining techniques commonly used for special steel include milling, turning, drilling, grinding, and broaching. These techniques are employed to shape and finish the special steel material according to the desired specifications and requirements. Additionally, special attention is given to selecting appropriate cutting tools, speeds, and feeds to ensure efficient and precise machining.

- Q: How does special steel contribute to the longevity of products?

- Special steel contributes to the longevity of products in several ways. Firstly, special steel is known for its exceptional strength and durability. It is specifically engineered to withstand extreme conditions, such as high temperatures, pressure, and corrosive environments. This makes it ideal for use in various industries, including aerospace, automotive, and construction. The high strength of special steel allows products to withstand heavy loads and resist deformation, ensuring they remain intact and functional for an extended period. For instance, in the construction industry, special steel is commonly used in structural components like beams and columns, which provide the necessary support and stability to buildings over many years. Moreover, special steel has excellent resistance to wear and abrasion. It can withstand constant friction, impact, and contact with other materials without significant deterioration. This characteristic is crucial in industries where products are subject to continuous use, such as machinery, tools, and equipment. The use of special steel in these applications ensures that the products remain in good working condition for a longer time, reducing the need for frequent repairs or replacements. Furthermore, special steel has exceptional corrosion resistance, making it highly resistant to rust and other forms of corrosion. This property is particularly beneficial in products exposed to harsh environments or chemicals, such as marine vessels, pipelines, and chemical processing equipment. By using special steel, manufacturers can significantly extend the lifespan of these products, minimizing the risk of failure or breakdown due to corrosion. In summary, special steel contributes to the longevity of products by providing superior strength, durability, wear resistance, and corrosion resistance. Its exceptional properties allow products to withstand harsh conditions, heavy loads, and continuous use, ensuring they remain functional and reliable for an extended period. By incorporating special steel into their designs, manufacturers can significantly enhance the lifespan of their products, leading to cost savings, improved reliability, and customer satisfaction.

- Q: What are the main applications of special steel in the oil and gas equipment?

- Special steel is widely used in the oil and gas equipment industry primarily for its exceptional strength, corrosion resistance, and ability to withstand high temperatures and pressure. It is extensively used in the production of drilling tools, pipelines, valves, and other critical components that are required to operate in harsh and demanding environments. The main applications of special steel in this industry include drill bits, wellhead equipment, subsea equipment, and offshore platforms, all of which rely on the superior properties of special steel to ensure safe and efficient operations in the oil and gas sector.

- Q: What are the requirements for special steel used in metalworking tools?

- The requirements for special steel used in metalworking tools include high hardness, excellent wear resistance, good toughness, and high heat resistance. Additionally, the steel should have good machinability, be able to hold a sharp edge, and have the ability to withstand high temperatures and loads without deforming or breaking.

- Q: How does sulfur affect the machinability of special steel?

- Special steel can be affected by sulfur in both positive and negative ways. On one hand, when a small amount of sulfur is added, it acts as a free-machining element. This leads to the formation of sulfide inclusions, which aid in breaking chips during machining. As a result, the surface finish is improved, tool wear is reduced, and cutting speeds are increased. This is particularly advantageous for high-speed machining operations. On the other hand, excessive sulfur content can be detrimental to machinability. When sulfur levels are high, brittle sulfide inclusions are formed, leading to poor machinability and decreased mechanical properties. This can cause increased tool wear, inferior surface finish, and slower cutting speeds. Additionally, sulfur can contribute to the development of built-up edge, further hindering the machinability of special steel. Therefore, maintaining an optimal sulfur content is crucial in order to achieve a balance between improved machinability and the desired mechanical properties. Proper control of sulfur levels in the steel composition, along with the use of appropriate machining techniques and tool selection, is necessary to achieve efficient and high-quality machining of special steel.

- Q: What are the applications of special steel in the oil and gas supply chain?

- Special steel has various applications in the oil and gas supply chain. It is commonly used in the construction of pipelines, drilling equipment, and offshore platforms. Special steel's high strength, corrosion resistance, and ability to withstand extreme temperatures make it ideal for these applications. Additionally, special steel is used in the manufacturing of valves, fittings, and other components that are crucial for the efficient and safe operation of the oil and gas supply chain.

- Q: What is the role of research and development in advancing special steel technology?

- The role of research and development in advancing special steel technology is crucial. Through continuous research and development efforts, new and improved manufacturing processes, alloys, and applications for special steel can be discovered and developed. This leads to advancements in the properties and performance of special steel, making it more durable, resistant to wear and corrosion, and capable of meeting the evolving needs of industries such as automotive, aerospace, and energy. Additionally, research and development help in optimizing production techniques, reducing costs, and promoting sustainability in the special steel industry. Overall, research and development play a vital role in pushing the boundaries of special steel technology, enabling innovation and driving progress in various sectors.

Send your message to us

Spring Steel Round Bar Hot Rolled

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords