Steel Structure in Angle Form with All Sizes and All Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

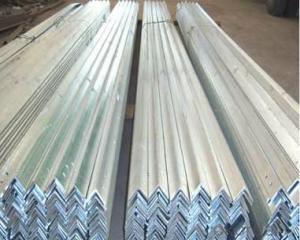

1. Structure of Steel Structure in Angle Form Description:

Steel structure in angle form is a main kind of structure steel and the section is like a letter L. We use steel structure in angle form for structure construction. Steel structure in angle form can be erected as soon as the materials are delivered on site. High strength, stiffness, toughness, and ductile properties are advantages of this kind of Steel structure in angle form.

2. Main Features of Steel Structure in Angle Form:

• Strength - Having high strength, stiffness, toughness, and ductile properties, structural steel is one of the most commonly used materials in commercial and industrial building construction.

• Constructability - Steel equal angle Bar can be developed into nearly any shape, which are either bolted or welded together in construction. Structural steel can be erected as soon as the materials are delivered on site, whereas concrete must be cured at least 1–2 weeks after pouring before construction can continue, making steel a schedule-friendly construction material.

• Fire resistance - Steel is inherently a noncombustible material. However, when heated to temperatures seen in a fire scenario, the strength and stiffness of the material is significantly reduced. The steel equal angle bar can be enveloped in sufficient fire-resistant materials, increasing overall cost of steel structure buildings.

3. Steel Structure in Angle Form Images:

4. Steel Structure in Angle Form Specification:

Angle | KG/M | Angle | KG/M | Angle | KG/M | Angle | KG/M |

20X20X3 | 0.889 | 60X60X5 | 4.570 | 90X90X8 | 10.946 | 130X130X12 | 23.600 |

20X20X4 | 1.145 | 60X60X6 | 5.427 | 90X90X9 | 12.220 | 130X130X13 | 25.400 |

25X25X2 | 0.763 | 63X63X4 | 3.907 | 90X90X10 | 13.476 | 130X130X14 | 27.200 |

25X25X3 | 1.124 | 63X63X5 | 4.822 | 90X90X15 | 15.940 | 130X130X16 | 30.900 |

25X25X4 | 1.459 | 63X63X6 | 5.721 | 100X100X6 | 9.366 | 140X140X10 | 21.488 |

30X30X2 | 0.922 | 63X63X8 | 7.469 | 100X100X7 | 10.830 | 140X140X12 | 25.522 |

30X30X3 | 1.373 | 63X63X10 | 9.151 | 100X100X8 | 12.276 | 140X140X14 | 29.490 |

30X30X4 | 1.786 | 70X70X4 | 4.372 | 100X100X10 | 15.120 | 140X140X15 | 31.451 |

36X36X3 | 1.656 | 70X70X5 | 5.397 | 100X100X12 | 17.898 | 140X140X16 | 33.393 |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about the corrosion of the products?

When the steel equal angle bar in contact with water, can corrode, creating a potentially dangerous structure. Measures must be taken in structural steel construction to prevent any lifetime corrosion. The steel can be painted, providing water resistance. Also, the fire resistance material used to envelope steel is commonly water resistant.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③What is the difference between steel angle bar and traditional material?

Steel equal angle bar differs from concrete in its attributed compressive strength as well as tensile strength.

- Q: How are steel angles priced?

- Several factors typically influence the pricing of steel angles. One of these factors is the current market price of steel, which is influenced by elements such as supply and demand, global economic conditions, and fluctuations in the costs of raw materials. The price of steel angles can also be affected by their size and dimensions, with larger and thicker angles generally costing more. The grade and quality of the steel used in the angle also play a role in determining its price. Steel angles made from higher-grade materials, such as stainless steel or alloy steel, tend to be more expensive due to their superior strength and resistance to corrosion. Furthermore, the quantity of steel angles being purchased can impact the price. Bulk orders or larger quantities often qualify for volume discounts, which can reduce the overall cost per unit. Lastly, the pricing of steel angles may also take into account transportation and logistics costs. Factors such as shipping distances, handling fees, and any additional services required for delivery can all contribute to the final price. In conclusion, the pricing of steel angles is determined by a combination of market conditions, size and dimensions, grade and quality, quantity ordered, and transportation costs. It is important to consider these factors when evaluating and comparing prices from different suppliers.

- Q: What are the different grades of steel used for angles?

- The different grades of steel commonly used for angles include A36, A572, and A588.

- Q: What are the different connections used with steel angles?

- There are several different connections that can be used with steel angles, including bolted connections, welded connections, and clip connections. Bolted connections involve using bolts and nuts to connect the angles to other structural members. Welded connections involve fusing the angles to the other members using a welding process. Clip connections involve using clips or brackets to secure the angles to the other members. The choice of connection depends on factors such as the load requirements, design specifications, and fabrication capabilities.

- Q: Can steel angles be used in seismic applications?

- Yes, steel angles can be used in seismic applications. Steel angles are commonly used in seismic applications due to their high strength and ductility properties. They are often used in the construction of steel moment frames and bracing systems, which are designed to resist lateral forces caused by seismic events. Steel angles are particularly effective in providing structural support and stability in areas prone to earthquakes. They can be used as diagonal braces, gusset plates, or stiffeners to enhance the seismic performance of buildings and structures. Additionally, steel angles can be easily fabricated and installed, making them a cost-effective choice for seismic applications.

- Q: What is the fire resistance rating of steel angles?

- The fire resistance rating of steel angles depends on various factors such as the size and thickness of the angle, the type of steel used, and the specific fire protection measures implemented. Steel is inherently fire-resistant due to its high melting point and low thermal conductivity. However, the fire resistance rating can be enhanced by applying fireproofing materials, such as intumescent coatings or fire-resistant boards, to the steel angles. These fire protection measures can significantly increase the fire resistance rating of steel angles by providing insulation and slowing down the transfer of heat to the steel. The specific fire resistance rating can vary based on the thickness and type of fireproofing materials used. For example, a steel angle with a certain fireproofing coating may have a fire resistance rating of 60 minutes, meaning it can withstand exposure to fire for up to 60 minutes before losing its structural integrity. It is important to consult local building codes, regulations, and fire safety standards to determine the specific fire resistance requirements for steel angles in a particular application. These standards can provide guidance on the necessary fire protection measures and the minimum fire resistance ratings that need to be met in different construction scenarios.

- Q: What are the different grades of steel used for manufacturing steel angles?

- The different grades of steel used for manufacturing steel angles include A36, A572, A588, and A992.

- Q: Can steel angles be used in the construction of museums?

- Yes, steel angles can be used in the construction of museums. Steel angles are commonly used as structural components in construction projects, including museums. They provide strength, stability, and versatility, making them suitable for various architectural and design requirements in museum construction.

- Q: What are the benefits of using hot-rolled steel angles?

- Hot-rolled steel angles offer several benefits, including high strength and durability, excellent structural integrity, and cost-effectiveness. They are ideal for various construction and manufacturing applications, providing stability and support in building frames, bridges, and machinery. Additionally, their malleability allows for easy fabrication and customization, making them a versatile choice for architects and engineers.

- Q: What is the difference between galvanized and black steel angles?

- There are two types of steel angles: galvanized and black steel angles. These two types have different characteristics and uses. Galvanized steel angles are coated with a layer of zinc, providing protection against corrosion. To achieve this, the steel angles are immersed in molten zinc, allowing the zinc to bond with the steel surface. This zinc coating increases the durability and lifespan of the steel angles, making them resistant to rust and other forms of corrosion. Galvanized steel angles are commonly utilized in outdoor applications, such as construction projects, fencing, and marine environments where exposure to moisture and harsh weather conditions is a concern. On the other hand, black steel angles are not coated with any protective layer. They are made from raw steel, giving them a black appearance. Black steel angles are typically employed in indoor applications, such as structural support, framing, and general fabrication. Due to their lack of protection against corrosion, they are not suitable for outdoor use or environments with high moisture content. In conclusion, the key distinction between galvanized and black steel angles lies in their coating and resistance to corrosion. Galvanized steel angles possess a zinc coating that shields them from rust and corrosion, making them suitable for outdoor applications. Conversely, black steel angles lack any protective coating and find their primary use indoors for structural support and general fabrication purposes.

- Q: Can steel angles be used for staircases?

- Yes, steel angles can be used for staircases. Steel angles are commonly used as structural supports in construction, including for staircases. They provide strength and stability to the staircase structure and can be designed to meet specific load-bearing requirements.

Send your message to us

Steel Structure in Angle Form with All Sizes and All Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords