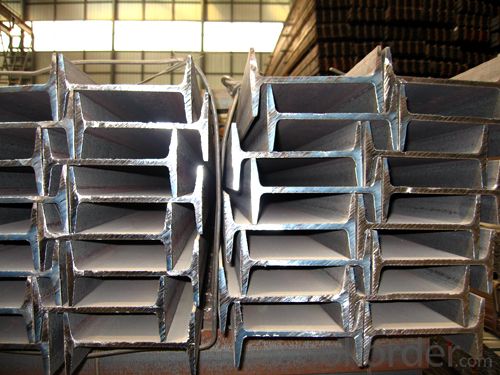

Hot Rolled Q235 Steel Structural I-Beam

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Q235 Steel Structural I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Q235 Steel Structural I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Brand: Baoming

Grade: SS400 – SS490

Model Number: GTLM-price-1201

Dimensions:

Leg Height: 95 – 2235.10mm

Depth: 55 – 119.5mm

Place of Origin: Guizhou, China

Color: As per customer request

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel I-beams be used for pedestrian bridges over rivers or canals?

- Pedestrian bridges over rivers or canals can indeed utilize steel I-beams. The utilization of steel I-beams is widespread in the construction of bridges due to their exceptional strength, durability, and versatility. They possess the capability to span great distances and endure heavy loads, rendering them ideal for pedestrian bridges that necessitate safe passage for foot traffic. Furthermore, steel I-beams exhibit resistance against the damaging effects of water and adverse weather conditions, a critical factor for bridges constructed above rivers or canals. These beams can be custom designed and fabricated to fulfill the precise requirements of the bridge, ensuring its ability to withstand the necessary loads and provide pedestrians with a secure crossing.

- Q: What are the typical deflection limits for steel I-beams?

- Steel I-beams have varying deflection limits depending on their application and design requirements. Structural engineering commonly follows general guidelines and standards in this regard. In most cases, the deflection limits for steel I-beams are determined by the beam's span length and the load it is expected to carry. Typically, the deflection limit is expressed as a ratio of the beam's deflection to its span length. For beams supporting live loads, like floor or roof beams, the deflection limit usually falls within the range of L/360 to L/240, where L represents the span length. This means that the beam's deflection should not exceed 1/360th to 1/240th of its span length. On the other hand, beams supporting dead loads, such as those in a building's structure, have more stringent deflection limits. In such cases, the deflection limit can be as low as L/480, ensuring minimal sagging or bending under the weight of the structure. It is important to note that these deflection limits are general guidelines and can vary based on specific design requirements, load conditions, and building codes in different regions. Structural engineers and designers are responsible for determining the appropriate deflection limits for each project, considering its unique requirements. Overall, the establishment of deflection limits for steel I-beams aims to maintain structural integrity and functionality while ensuring a safe and stable design.

- Q: Can steel I-beams be used for airport terminal structures?

- Yes, steel I-beams can be used for airport terminal structures. They are commonly employed in the construction of large buildings and infrastructure projects due to their strength, durability, and ability to support heavy loads. Steel I-beams provide structural stability and can effectively withstand the demands of an airport terminal, making them a suitable choice for such structures.

- Q: Can Steel I-Beams be used for mezzanine storage?

- Yes, Steel I-Beams can be used for mezzanine storage. They are commonly used in construction for their strength and load-bearing capabilities, making them suitable for supporting elevated storage platforms like mezzanines.

- Q: What are the common design considerations when using steel I-beams?

- Some common design considerations when using steel I-beams include determining the appropriate size and shape of the beam based on the structural load it needs to support, calculating the required strength and stiffness to ensure structural stability, considering the potential for deflection and buckling under load, and incorporating appropriate connections and supports to ensure proper installation and performance. Additionally, factors such as fire resistance, corrosion protection, and cost-effectiveness may also be taken into account during the design process.

- Q: Can steel I-beams be used for roof support?

- Indeed, roof support can be achieved by utilizing steel I-beams. These I-beams are frequently employed in construction to provide structural support owing to their robustness and longevity. They are specifically designed to bear substantial loads and ensure the stability of the edifice. When utilized for roof support purposes, steel I-beams can be positioned horizontally across the roof's expanse, facilitating the equitable distribution of the roof's weight and averting any sagging or potential collapse. They are commonly utilized in commercial and industrial structures that necessitate expansive roof spans. Additionally, steel I-beams can be tailored and engineered to meet precise load specifications and architectural designs, rendering them an adaptable option for roof support in diverse construction ventures.

- Q: Can steel I-beams be used for industrial platforms or catwalks?

- Yes, steel I-beams can certainly be used for industrial platforms or catwalks. Steel I-beams are known for their strength and durability, making them an excellent choice for such applications. They are capable of supporting heavy loads and can withstand the constant foot traffic and other industrial activities typically seen on platforms or catwalks. Additionally, steel I-beams can be easily customized to meet specific design and structural requirements, allowing for efficient and safe construction of industrial platforms or catwalks.

- Q: How do steel I-beams contribute to the overall durability and longevity of a structure?

- Steel I-beams play a crucial role in enhancing the overall durability and longevity of a structure due to their unique characteristics and properties. Firstly, the I-beam's design allows it to distribute weight evenly across its length, making it highly resistant to bending or warping under heavy loads. This feature is particularly important in structures with large spans or multi-story buildings where the I-beams provide critical support. Moreover, steel I-beams are known for their exceptional strength-to-weight ratio. This means that they can withstand significant loads while maintaining their structural integrity, without adding excessive weight to the structure. The high strength of steel allows for the use of smaller and lighter I-beams, reducing construction costs and facilitating the overall design process. In addition to their strength, steel I-beams are highly resistant to various environmental factors that can compromise a structure's durability. Steel is inherently non-combustible, providing excellent fire resistance compared to other building materials. This resistance to fire enhances the safety of the structure and reduces the risk of collapse in case of a fire emergency. Furthermore, steel I-beams are immune to several common issues that can affect other construction materials. Unlike wood, steel is not susceptible to rotting, termites, or other pests, which can significantly undermine the longevity of a structure. Steel is also highly resistant to corrosion and rust, thanks to protective coatings such as galvanization. This corrosion resistance ensures that the I-beams maintain their strength and structural integrity over time, minimizing the need for costly repairs or replacements. Lastly, steel I-beams provide the advantage of being highly versatile and customizable. They can be fabricated to exact specifications, allowing for precise design and optimal load-bearing capacity. This flexibility enables architects and engineers to create robust structures that can withstand various stresses and environmental conditions, further enhancing their longevity. In conclusion, steel I-beams contribute significantly to the overall durability and longevity of a structure through their even weight distribution, high strength-to-weight ratio, resistance to environmental factors, and versatility. By incorporating steel I-beams into a construction project, engineers can ensure a long-lasting and reliable structure that can withstand the test of time.

- Q: What are the design considerations for steel I-beams?

- To ensure structural integrity and optimal performance when designing steel I-beams, several important considerations must be taken into account: 1. Load-bearing capacity: The ability of steel I-beams to withstand the load they will support is a primary design consideration. Calculating the maximum expected loads and designing the beam with sufficient strength and stiffness to support these loads without excessive deflection or failure is crucial. 2. Span length: Another key consideration is the distance between supports, known as the span length. Longer spans require larger and stronger beams to prevent sagging or excessive deflection. Careful selection of the beam's size, shape, and the spacing and stiffness of the supports is necessary to accommodate the desired span length. 3. Material selection: Choosing the right steel material is critical in beam design. Different grades and types of steel have varying properties that affect load-bearing capacity and structural performance. The appropriate steel grade must be selected to meet specific design requirements. 4. Shape and dimensions: The shape and dimensions of the I-beam significantly impact its performance. The beam's cross-sectional shape, resembling the letter "I," provides an optimal strength-to-weight ratio. Determining the dimensions (width, depth, and thickness of the flanges and web) carefully is necessary to ensure sufficient strength and stiffness while minimizing material usage. 5. Connection details: Proper connection design and detailing between steel I-beams and other structural elements are essential for maintaining overall structural integrity. Effective and secure load transfer to supports or other structural members, while accommodating potential movements and deformations, must be ensured. 6. Fire resistance: Steel can weaken when exposed to high temperatures, making fire resistance a crucial consideration. Various methods, such as fireproof coatings, fire-rated insulation, or encasing beams in fire-resistant materials, can enhance fire resistance. 7. Cost and constructability: Considering cost and constructability is important in designing steel I-beams. Minimizing material usage and fabrication costs while ensuring ease of construction and installation is a goal. Optimizing beam sizes and shapes to achieve the desired performance at an economical cost is often done. In conclusion, designing steel I-beams involves balancing load-bearing capacity, span length, material selection, shape, connection details, fire resistance, cost, and constructability. By carefully considering these factors, engineers can create steel I-beams that meet structural requirements while ensuring safety, efficiency, and durability.

- Q: Are there any maintenance requirements for steel I-beams?

- Yes, there are maintenance requirements for steel I-beams. While steel is a durable material, it is still susceptible to certain factors that can affect its integrity over time. Regular maintenance is necessary to ensure the longevity and safety of steel I-beams. One important maintenance requirement for steel I-beams is inspection. Regular visual inspections should be conducted to identify any signs of damage or deterioration. This includes checking for cracks, corrosion, or any other structural issues that may compromise the strength of the I-beams. Inspections can help identify potential problems early on and allow for timely repairs or replacements. Another maintenance requirement is cleaning. Steel I-beams should be cleaned periodically to remove dirt, debris, or any corrosive substances that may have accumulated on the surface. Cleaning can be done using a mild detergent and water, or specialized cleaning solutions depending on the level of dirt or corrosion present. Regular cleaning helps prevent the buildup of contaminants that can accelerate corrosion or weaken the steel. Additionally, it is important to address any identified issues promptly. If any cracks, corrosion, or damage are found during inspections, it is crucial to take immediate action to repair or replace the affected I-beams. Ignoring or delaying repairs can lead to further deterioration and compromise the structural integrity of the steel beams. Furthermore, in some cases, steel I-beams may require protective coatings or paints to prevent corrosion. These coatings act as a barrier between the steel and its environment, preventing moisture or other corrosive elements from reaching the surface. The type and frequency of coating application may vary depending on the specific conditions and requirements of the application. In conclusion, regular inspection, cleaning, and prompt repairs or replacements are essential maintenance requirements for steel I-beams. By following these maintenance practices, the longevity and performance of steel I-beams can be ensured, ultimately contributing to the safety and durability of structures they support.

Send your message to us

Hot Rolled Q235 Steel Structural I-Beam

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords