Hot-dipped Elector Galvanized Iron Wire for Building materials or Binding Wire

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvanized Iron Wire Description:

Galvanized Iron Wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.It can be used for many wire mesh wove, like chain link fence, mine screen mesh etc.

The electro or hot dip Galvanized Iron Wire can also be used in various automotive components; communication equivaments; packing products; manufacturer of galvanized barbed wire; galvanized wire rope of low and high strength; used in medical components etc

2.Main Features of Galvanized Iron Wire:

• Use widely

• Corrosion- resistant

• Durable

• Practical use

• Beauty Surface

• Versatile

3. Galvanized Iron Wire Images

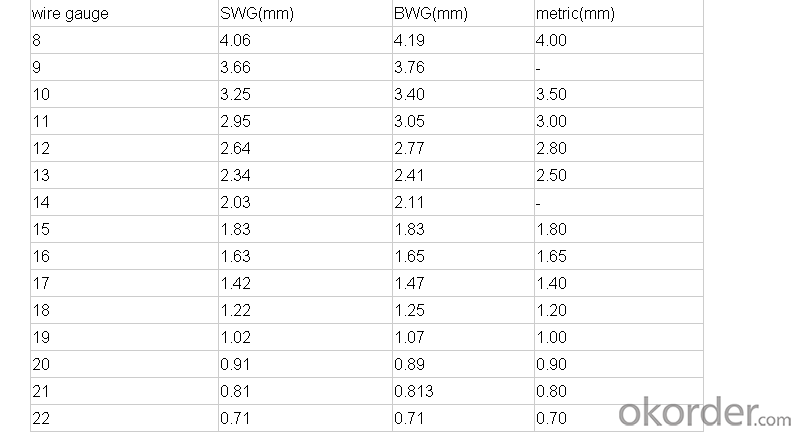

4.Galvanized Iron Wire Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Our company is a professional manufacturer of wire in China. The mainly product is Galvanized Iron Wire and black annealed iron wire. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world. Different kinds of wires and mesh are available according to customer’s requirements.

②Is your Galvanized Iron Wire suited to work rework?

Certainly.First, there is good performance for drawing the Q195 wire rod as the basic material;Second, the wire need to anneal in the drawing and redrawing processing.Annealing makes the wire soft and can not break easily, and also make a better cutting performance.

③How long can we receive the product after purchase?

In the purchase of Galvanized Iron Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: wire diagram and manual

- a small boats wiring cant be very complicated. If you're needing to replace it get a book called Small Boat Wiring or a similar. If you're trying to find a fault with existing wiring simply trace the existing wires remake all the connections as you go. I suggest you pull the lot out redo it properly. Except for the electric start you dont need super heavy cabling for a small boat. Tinned multi strand wire with a core diameter of about 2 mm is fine. Get a roll of red one of black ( or use red/black figure 8 cable) From the battery fit a service fuse of about 15 - 20 amp in line with the positive cable right near the battery. Use only properly crimped screwed or soldered connections. If the connection is ever likely to get wet then cover the connection with a piece of heatshrink tubing with a good smear of neutral cure silicone inside it. The silicone should squeeze out both ends of the tube when you shrink it. Dont make any joints mid run ( never in the bilges). Make sure the wiring is secured where it is out of the way is neat. Support the wire near the connections. Run from the switch panel to each item as a separate circuit, dont daisy chain. Give each item its own cable including the return (black wire) brought back to the panel. Be neat make a permanent record of what you've done. Fuse each circuit with a fuse rated about 50% above what that item should draw. Always carry plenty of spare fuses.

- Q: let me start off with I am not an electrician I just do basic stuff for side work I came in the project at the end. The lady wanted me to wire in 6 receptacles, a light switch and light fixture all on one circuit. everything is good except for the receptacle at the start of the circuit it has the lead/ hot coming in the power to the other receptacles going out and the power to the light going out (3 groups, 9 wires total). normally I would have used a junction box but I didn't pull the wire. How can I wire this. Would a 15 amp receptacle work?

- A 15 Amp receptacle will work, of course, but the receptacle box is most likely already overfilled. So in order to keep the wire count down, your best way to go is to buy a receptacle that uses screw down connector tabs. (NOT the kind that you have to put the wire under the screw, but the kind that you insert the wire into the back and then turn the screw down to clamp onto it!) The receptacle is a little more money but it would be worth the expense to make this hook up work. Hot wire (Black): Connect all three black wires to the back of the receptacle on the brass colored screws. Common wire (White): Connect all three white wires to the back of the receptacle on the silver colored screw. Ground: make a short pigtail of bare copper wire (about 6 or 7 inches long). Then connect the pigtail to the other 3 bare copper ground wires using a wire nut. Then connect the other end of the pigtail to the grounding connection of the receptacle. MAKE SURE THE POWER IS OFF WHEN YOU DO ALL OF THIS SO THAT YOU CAN LIVE TO TELL THE TALE! :-)

- Q: Is high quality CAT-5 ok to wire surround sound speakers to the receiver?

- Do not use cat5 wiring. Yes it will transmit the sound but the wires gage is too small. It is also solid core wiring. Solidcore wiring is not the best for speakers. Use a good quality oxygen free copper speaker cable around 16 gage up to 50 ft. If you have 100 watts/channel or more you should use a 14 gage wire. If you are over 150watts/channel use 12 gage. Remember the wire gets bigger as the gage goes lower.12 gage wire is thicker then 18 gage wire. I personally like the Moster XP brand of speaker cable. it is not that expensive. Sometimes moster cable can be overpriced but not so much in the case of this wire. It is very flexible and will layout nice on the floor. I have purchased wire in the past that was similarly priced and it was garbage. The 20% rule stated above is indeed whack as I would have been spending $2,400 on speaker cables. NOT GONNA HAPPEN. About a $1 to $2 per foot is resonable. You will get a more than adequate wire for that price. That is about what the Monster XP cable I use costs. But copper is expensive now so the cost may be higher.

- Q: Im installing a motion sensor which comes with 3 wires,red black and white and want to connect it to a indoor light that only comes with 2 wires white and black.How do I go about installing them and powering them?

- To be honest, it seems you might be better served getting an electrician. If not... 1st, make sure to turn off the power. I'd imagine the red and black wires are for the incoming power (to the motion switch) and the outgoing power (from the motion sensor to the light). Look for markings on the wires or near where they go into the sensor (didn't this sensor come with instructions?), LINE designates incoming power, LOAD is for the load being served (the light). White is the common wire and will connect to the other white wire. If I had to guess, I'd say the red is incoming power, black is outgoing to the light. Whatever you do, BE CAREFUL, electricity is no joke.

- Q: How can it be possible to create a high voltage and have a small gauge wire? Example: 3gj or 3000mw in a small wire (just an example)

- Assuming the wires aren't linked, and assuming the voltages are with appreciate to floor. There's no difference between the wires, or as a minimum there need not be any variations. What makes you factor there may be. Voltage is only a knowledge utilized to the wire, through batteries for example. When you have a 1.5 volt battery and a ninety volt battery (that you would be able to purchase these, but steeply-priced) both with the bad tied to floor. Now take 2 small pieces of copper wire, about an inch long. Lay each one on the constructive terminal of one of the crucial batteries. That meets your stipulations. Nothing happens to the wires.

- Q: what are the differences between wired and wireless microphones? and what are the Pros and Cons of having a wired mic, pros and cons of a wireless?Thanks......

- Wired microphones have a wire to connect it. Wireless ones don't. Pros and cons? Do you want wires?

- Q: The spark plug wire on my dirt bike needs to be replaced because it was touching the exhaust and it burned through.I was wondering if the ignition coil and spark plug wire are one piece and need to both be replaced or is there someway to disconnect spark plug wire? They spark plug wire doesn't seem to be pluged in, but it seems to be one piece. Does anyone know?

- Many small coils on dirt bikes, small engines and scooters have the spark plug wire pressed and glued into coil- usually replace coil and wire together as plug wire basicly not replacable in field.. Aftermarket coils can be used with seperate wire or maybe use a car coil from VW beetle type or in couiple cases i know plain Ford patterns. BMW /5 had 2 Bosch coils with replaceable wires- what kind of bike you working with. Clamp car coil to front frame, run extended wire loom to coil, use metal core spark plug wire and marine plug cap- used to be common or 2 stroke racers. In emergency you can cut wire cored wires and splice in another piece, tape it up .

- Q: i need an egr wiring Diagram for a 2000 Chevy Malibu. the wires got pulled out of the weather tight connector. if anyone can help i'd appreciate

- Connector view for the GM linear EGR valve are as follows: Pin# A=gray/w black wire,Pin# B=solid black wire,Pin# C=brown/w white wire,Pin# D=brown/w white wire(see note) and Pin# E=solid red wire! NOTE since pin C+D have the same color wire the correct wire must be identified by checking the voltage with the KOEO (key on engine off) the right brown/w white wire should have a 5volt reference voltage with the key on engine off! Hope this helps.

- Q: Need to wire three ceiling fans in series

- NO, you do NOT need or want to wire multiple fixtures in series. You ALWAYS wire fixtures in parallel. You most likely mean you want to wire three ceiling fans to be controlled by a single switch. Since you failed to actually ask a question, I will guess you want to know NOW to wire them. The answer is EXACTLY the same as wiring one ceiling fan, with the 'live' wire from the switch extending to each fixture. If that is not enough to help you, I STRONGLY recommend professional help.

- Q: What happens when you hook these 2 wires up right along each other?

- if you have an rca tv which works with 12 volts.......if the wires not connected to battery...there no problem. if connected to battery....the fuse blows.(close to battery on wire)....if there is no fuse....wires burn...risk of fire....do not forget...every device works with car battery MUST and MUST be eouipped fuse .

Send your message to us

Hot-dipped Elector Galvanized Iron Wire for Building materials or Binding Wire

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches