Hot-dip Zinc Coating Steel Building Roof with Good Price Better Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof with Good Price Better Quality

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• High strength

• Good visual effect

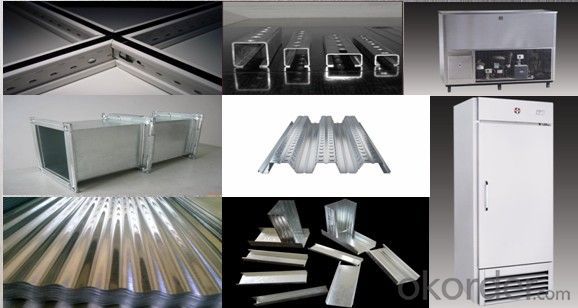

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

5.FAQ of Hot-Dip Galvanized Steel Sheet

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils inspected for uniformity using statistical analysis?

- Steel coils can be inspected for uniformity using statistical analysis through various techniques and procedures. The primary objective is to ensure that the steel coils meet the required specifications and have consistent quality throughout the entire coil. One common method of inspection is to collect a representative sample of steel coils from a batch or production run. These coils are randomly selected to ensure a fair representation of the entire batch. Statistical analysis is then performed on this sample to determine the uniformity of the coils. The first step is to measure various physical properties of the coils, such as thickness, width, weight, and surface defects. These measurements are recorded for each coil in the sample. The collected data is then analyzed using statistical techniques, such as mean, standard deviation, and range calculations. By calculating the mean values of the measured properties, it is possible to determine the average values for thickness, width, weight, etc. These mean values can be compared to the desired specifications to identify any deviations or inconsistencies. The standard deviation provides a measure of the variability or dispersion of the data, indicating how closely the coils conform to the desired specifications. A smaller standard deviation indicates greater uniformity. Additionally, range calculations can be performed to determine the difference between the maximum and minimum values of the measured properties within the sample. A smaller range suggests a higher level of uniformity. Statistical analysis can also involve the use of control charts, such as X-bar and R-charts, to visually monitor the variation in the measured properties over time. These charts provide a graphical representation of the data, allowing for the identification of any trends or out-of-control conditions. Overall, statistical analysis allows for a systematic evaluation of the uniformity of steel coils by providing objective measurements and statistical indicators. By analyzing the collected data, manufacturers can identify any deviations from the desired specifications and take appropriate corrective actions to ensure consistent quality throughout the production process.

- Q: What is the minimum thickness of a steel coil?

- The minimum thickness of a steel coil can vary depending on the specific requirements and standards set by the industry. However, in general, the minimum thickness of a steel coil is typically around 0.15 millimeters or 0.006 inches.

- Q: I am in the market for a good hunting knife under $100. I am primarily looking for a knife that will keep it's edge. What type of steel should I be looking for?

- Take a close look at the Cold Steel Master Hunter. I can't wait for my hunting knife to die so I can go get one.

- Q: What are steel coils?

- Steel coils are large, flat sheets of steel that have been rolled into a circular shape. They are commonly used in various industries, including automotive, construction, and manufacturing, for purposes such as making pipes, tubes, and sheet metal products.

- Q: i am debating weather to get the hercules rmx or the steel and from what i have read, the only differences between them is the rmx has a sound card (built in interface-to connect to the computer, correct me if im wrong) and that the steel has more effects. however, i cannot find out which effects it has so it would be a big help if someone can answer this for me.thanx

- I guess that since Steel doesn’t have headphones connection and a built-in soundcard, one won’t be able to play a track on one deck and prelisten the track on the other without using an external usb soundcard, right? I was wondering what’s the point in releasing a product like this if you also have to buy a bunch of equipment to be able to do sth “fondamental”: play while preparing your next song. However since the steel is meant for DJ’s who already have a great soundcard, but I don’t see why a Steel+sound card is ONLY for pro’s. Yes it’s designed for pro’s but you can use it as a beginner. Some consoles you also need to consider: Hercules Steel/RMX, Numark OMNI/Steath. It's all personal decision. Peace, Love Happiness

- Q: What is the type of stainless steel used in knifes.

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

- Q: What are the common packaging defects in steel coils?

- Some common packaging defects in steel coils include improper wrapping, inadequate strapping or banding, loose or damaged packaging materials, moisture or water damage, and insufficient protection against impacts or abrasion.

- Q: Does anyone know if there is any info on Steel Manufacturing techniques, utilyzing electro/mechanical methods in order to create carbon nanotubes from the %C already inherant in the steel. In other words just modifying the Geometry of the Carbon the already makes up some of the steel.

- I don't think that would work. First off, there's not enough carbon in steel - even very high carbon steels are only about 2% carbon. Second, the iron atoms in steel form a crystal lattice, in the shape of a cube, with another iron atom in the middle of the cube. Each cube is about 0.3 nm per side. Carbon atoms work their way into the crystals and displace the iron atoms. But a carbon nanotube is around 1 nanometer in diameter - that's 3 times as big as the iron lattice! So a nanotube wouldn't fit. One thing you might do, however, is make a composite - mix the materials together on a scale a little bigger than the atomic scale that the iron and carbon mix to make steel. Just like a carbon fiber bicycle frame or ski pole is strands of carbon (much bigger and not as strong as nanotubes) held together with epoxy, you could hold nanotube strands together with metal. Not sure it would be good for armor, but if you can figure out a way to do it, I'm sure someone will come up with a use for it!

- Q: I bought a stainless steel mood ring two days ago, but would it rust?Thanks in advance!

- This Site Might Help You. RE: Do stainless steel mood rings rust? I bought a stainless steel mood ring two days ago, but would it rust? Thanks in advance!

- Q: Can steel coils be used in electrical applications?

- Yes, steel coils can be used in electrical applications. Steel coils are often used as magnetic cores in transformers and inductors, which are essential components in electrical circuits. The steel used in these coils is typically a type of high-quality electrical steel that has specific magnetic properties, such as low core losses and high permeability. These properties allow the steel coils to efficiently transfer electrical energy between different components of the circuit. Additionally, steel coils can also be used in other electrical applications, such as in the construction of electric motors and generators. Overall, steel coils are widely utilized in electrical applications due to their magnetic properties and their ability to handle high currents and temperatures.

Send your message to us

Hot-dip Zinc Coating Steel Building Roof with Good Price Better Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords