Hot-Dip Galvanized Steel Roof with Good Quality of China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

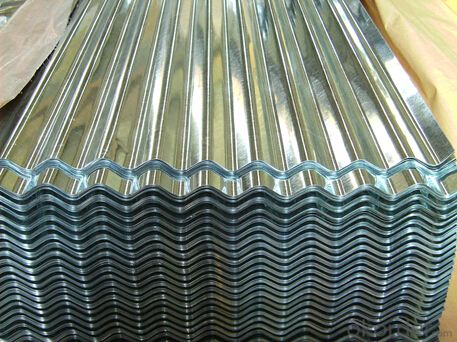

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: How are steel coils used in the manufacturing of electrical transformers?

- Steel coils are used in the manufacturing of electrical transformers as they provide a strong and durable core for the transformer. The coils are typically made of high-grade electrical steel, which has low electrical resistance and high magnetic permeability. These properties allow the coils to efficiently conduct and transform electrical energy, ensuring the proper functioning of the transformer.

- Q: How do steel coils compare to other materials in terms of cost?

- Compared to other materials, steel coils offer greater cost-effectiveness. This is due to the fact that steel is widely accessible and abundant, leading to relatively low production costs. Moreover, steel coils boast an extended lifespan and require minimal upkeep, resulting in reduced expenses over time. The exceptional durability and strength of steel also make it an optimal selection for a wide range of applications, further augmenting its cost-effectiveness. When contrasted with materials such as aluminum or copper, steel coils are typically more economical, making them the preferred option for numerous industries.

- Q: What are the advantages of using galvanized steel coils?

- Using galvanized steel coils in various applications offers a multitude of benefits. Firstly, their resistance to corrosion is highly impressive. Through the process of galvanization, a protective layer of zinc is applied to the steel, effectively guarding it against moisture, chemicals, and other elements that can lead to rust and corrosion. As a result, galvanized steel coils are an excellent choice for outdoor applications that are exposed to harsh weather conditions or corrosive substances. Secondly, galvanized steel coils boast exceptional durability and longevity. The zinc coating provides an additional protective layer, enhancing the steel's resistance to wear and tear. Consequently, galvanized steel coils have a longer lifespan compared to other steel types, reducing the frequency of replacements and saving costs in the long term. Moreover, galvanized steel coils exhibit remarkable strength and structural integrity. The zinc coating not only offers corrosion resistance but also augments the overall strength of the steel. This makes galvanized steel coils an ideal option for applications that demand a robust and dependable material, such as construction, automotive, and industrial manufacturing. Furthermore, working with galvanized steel coils is effortless and requires minimal maintenance. The zinc coating creates a smooth and uniform surface, facilitating tasks like painting, welding, and fabrication. Unlike other coatings or finishes, galvanized steel coils do not necessitate regular maintenance or additional protective measures, reducing the time and effort required to keep them in optimal condition. Lastly, galvanized steel coils are environmentally friendly. The zinc coating used in galvanization is recyclable, making it a sustainable choice for various industries. Additionally, the extended lifespan of galvanized steel coils diminishes the need for frequent replacements, thereby reducing waste and the overall environmental impact. In conclusion, the advantages of utilizing galvanized steel coils encompass corrosion resistance, durability, high strength, easy workability, low maintenance, and environmental sustainability. These benefits have solidified galvanized steel coils as a favored option in a wide range of applications, spanning from construction and manufacturing to automotive and infrastructure projects.

- Q: Are steel buildings more durable than concrete building?

- Yes of course they look nice and I think they are more durable and weather resistant than conventional concrete buildings. So if you are thinking of constructing a building then opt for steel buildings buddy :)

- Q: How do steel coils contribute to the agricultural sector?

- Steel coils contribute to the agricultural sector in various ways. Firstly, steel coils are used in the manufacturing of agricultural machinery and equipment such as tractors, harvesters, and irrigation systems. These machines are essential for efficient farming operations, helping farmers increase productivity and reduce labor costs. The strength and durability of steel coils ensure that the machinery can withstand the harsh conditions of the agricultural environment. Additionally, steel coils are used in the construction of storage facilities and warehouses for storing agricultural products. These structures need to be strong and resistant to external elements to protect the crops from damage. Steel coils provide the necessary strength and stability required for constructing these storage facilities, ensuring the safe storage of agricultural produce. Furthermore, steel coils are used in the fabrication of fencing and other agricultural infrastructure. Fencing is crucial in protecting crops from animals and preventing trespassing. Steel coils provide a robust material for fencing, ensuring the security and protection of agricultural lands. Moreover, steel coils are utilized in the production of irrigation pipes and systems. Efficient irrigation is vital for the growth and yield of crops, especially in areas with limited water resources. Steel coils are used to manufacture pipes that can withstand high pressure and are resistant to corrosion, ensuring the efficient distribution of water throughout the agricultural fields. In summary, steel coils play a significant role in the agricultural sector by providing the necessary materials for manufacturing machinery, constructing storage facilities, fencing, and irrigation systems. The strength, durability, and resistance to harsh conditions make steel coils an essential component in enhancing agricultural productivity, protecting crops, and ensuring efficient farming practices.

- Q: How are steel coils used in the manufacturing of transmission systems?

- Steel coils are used in the manufacturing of transmission systems as they are shaped and formed into various components such as gears, shafts, and bearings. These components provide strength, durability, and precision to the transmission system, ensuring smooth power transfer and efficient operation of vehicles and machinery.

- Q: If I wear a pair of thick wool socks, is walking around in the snow with steel-toed boots going to be a problem? I'm wondering if the steel will make my toes too cold.

- Dr. Martens makes a number of pairs of steel toed work boots. I have never owned a pair of their steel toes, but I have owned several pairs of their shoes and boots, the oldest of which is fifteen years old and still going strong. They take a couple of weeks to break in, but once they do, they are practically molded to your foot. They are more expensive, but they last a LONG time. Good Luck!

- Q: I have two theories, which one's correct?My book says that steel is made up of 98% iron and 2% carbon.98% of iron's molar mass (55.85 g/mol) is 54.733.2% of carbon's molar mass (12.01 g/mol) is .2402.If you add them up that gives you that steel has a molar mass of 54.97 g/mol.However, steel's chemical formula is Fe(3)CThat would make it's molar mass 179.56 g/mol.( Because 3(55.85) + 12.01 = 179.56 )Which one is correct?

- Steel is an alloy - a mixture not a compound; it doesn't have a chemical formula. Only elements and compounds have molecular weights, not mixtures that aren't composed of a uniform molecule, so neither answer is correct.

- Q: What are the different methods of surface cleaning for steel coils?

- There are several different methods available for surface cleaning of steel coils. The choice of method depends on the specific requirements and conditions. 1. Mechanical Cleaning: This method involves the use of mechanical tools such as wire brushes, sanding discs, or abrasive pads to physically remove dirt, rust, or other contaminants from the surface of the steel coils. It is commonly used for light cleaning and can be done manually or with the help of automated equipment. 2. Chemical Cleaning: Chemical cleaning involves the use of various cleaning agents or solvents to dissolve or loosen contaminants from the surface of steel coils. This method is effective for removing oil, grease, or stubborn dirt. Different chemicals can be used depending on the type of contaminants and the desired level of cleaning. It is important to follow safety guidelines and use appropriate protective equipment when using chemical cleaners. 3. Power Washing: Power washing or pressure washing utilizes a high-pressure water jet to remove loose particles, dirt, or contaminants from the surface of steel coils. This method is effective for large-scale cleaning and can be combined with chemical cleaners for enhanced results. It is important to adjust the water pressure according to the type of surface and use appropriate nozzles to prevent damage. 4. Pickling: Pickling is a chemical cleaning method that involves the immersion of steel coils in an acidic solution, typically a mixture of hydrochloric acid and sulfuric acid. This process removes scale, oxides, and other impurities from the surface of the steel. Pickling is commonly used for heavy-duty cleaning and preparation of steel coils before further processing or coating. 5. Electrolytic Cleaning: Electrolytic cleaning utilizes an electric current to remove contaminants from the surface of steel coils. The coils are immersed in an electrolyte solution, and the application of a direct current causes the contaminants to dissolve or dislodge from the surface. This method is particularly effective for removing rust or corrosion and can be used in conjunction with other cleaning methods. It is important to consider factors such as the type and condition of the steel coils, the level of cleanliness required, and any specific industry standards or regulations when choosing the appropriate method of surface cleaning. Regular maintenance and cleaning of steel coils are essential to ensure their longevity, performance, and resistance to corrosion.

- Q: How are steel coils used in the production of fireproof doors?

- Steel coils are used in the production of fireproof doors as they provide the necessary strength and durability to withstand high temperatures and prevent the spread of fire. The coils are formed into sheets or plates, which are then used to construct the framework and core of the fireproof doors. This ensures that the doors can effectively resist fire and protect buildings and occupants from its dangers.

Send your message to us

Hot-Dip Galvanized Steel Roof with Good Quality of China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords