Hot-dip Zinc Coating Steel Building Roof Walls -Good Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls -Good Price

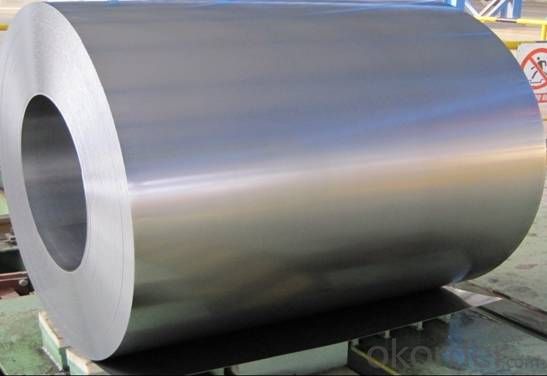

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

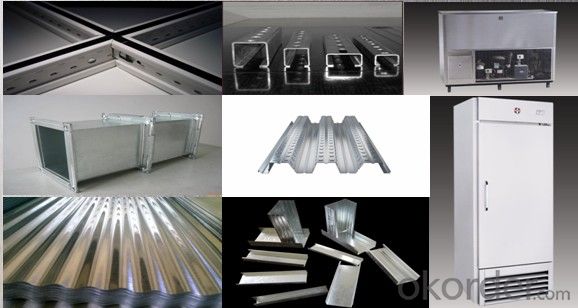

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the production of agricultural systems?

- Steel coils are used in the production of agricultural systems as they are often shaped into various components like frames, supports, and structures. These components provide strength, durability, and stability to agricultural equipment such as tractors, harvesters, and irrigation systems, ensuring their long-term functionality and reliability in demanding farming environments.

- Q: Where can you buy a steel polearm in a shop or if someone has a file in Scania than can you sell me one ill buy it for 150k my account is tonypark500

- you dont buy it, you earn it in the lottery cassandra was doing(it passed).

- Q: How are steel coils classified based on their thickness?

- Steel coils are classified based on their thickness into different categories such as light gauge, medium gauge, and heavy gauge.

- Q: This question gets beat to death from what ive seen online but im going to ask it since im searching for a few new knives. The question is as the titles states what is the best steel for a general purpose knife? I plan on buying several different types of knives, Folders, fixed blades, ect. I will carry them around with me all the time for basically anything i can think of to use it for. The reason i ask this question here is because looking online everyone has a differnt veiw. Some say stainless is too soft while others say carbon will chip and is more brittle. Even looking at just a single type of steel, carbon fort instance everyone has a different opinion as to whats best leaving me kind of lost for what i should get. Maybe the better word would be What is a good general purpose steel?. Any advice is much appreciated!!!!

- Fixed Blades: Folding Blades: CPM 3V CPM S35-VN 1095 CPM S30-V 5160 AUS-8 (when it's heat treated right)

- Q: Went to top gun range in Houston, Tx. Guy there said no steel bullets..Anyone know why? Think i can shoot them anywhere else? Perhaps an outdoor gun range? The are monarch FMJ 9mm steel rounds..Thanks!

- However, I cannot under any circumstance travel with loaded rifle magazines in my car. Those I have to load at the range because it would be illegal for me to travel to the range with loaded magazines. Even if I don't have a rifle in the car, I cannot possess loaded rifle magazines while traveling. All long guns (shotguns included) must be unloaded and secured in the vehicle, including magazines or tubes. There are several states with restrictions against traveling with loaded rifle magazines, so I'd suggest you check your state laws first, and if it is permissible in your state, then find out if the range will allow it too.

- Q: How are steel coils inspected for straightness?

- To ensure compliance with quality standards, steel coils undergo a variety of methods to inspect their straightness. Among these, visual inspection is commonly employed, wherein trained inspectors meticulously examine the coil's edges, surface, and overall shape for any visible flaws or irregularities that might indicate a lack of straightness. An alternative approach involves measuring the coil's straightness using precise instruments. This entails taking measurements at different points along the coil's length and comparing them to specified tolerances. Accurate assessment of the deviation from the desired straightness is achieved using techniques like laser measurements or straightness gauges. Moreover, certain coils undergo non-destructive testing, such as magnetic particle inspection or ultrasonic testing, to uncover any internal defects or stresses that may impact their straightness. These tests are capable of identifying hidden flaws that visual inspection alone may fail to detect. Additionally, some manufacturers employ automated inspection systems that leverage advanced technologies like computer vision or artificial intelligence. These systems swiftly scan the coil's surface and analyze it for any deviations from straightness, generating precise measurements and ensuring consistent quality. In summary, the inspection of steel coils to verify their straightness involves a combination of visual inspection, precise measurements, non-destructive testing, and advanced technologies. These methods work together to identify any deviations from the specified straightness, ensuring that only coils meeting the required standards are utilized in various applications.

- Q: I have my grandpa's navy knife from ww2, a mk2 combat knife i think, and i was wondering what type of steel it is made of. I'm guessing it's a high carbon steel, i'd just like to know exactly what grade.

- I would get a 1095, serrated edge, tanto style, with either a good quality rubberized or bone handle.

- Q: What are the different surface treatments for steel coils?

- There are several different surface treatments available for steel coils, depending on the desired outcome and application. Some of the most common surface treatments for steel coils include: 1. Hot-dip galvanizing: This process involves immersing the steel coils in a bath of molten zinc, which forms a protective layer on the surface of the steel. Hot-dip galvanizing provides excellent corrosion resistance and is often used for outdoor applications. 2. Electro-galvanizing: Similar to hot-dip galvanizing, but instead of immersing the steel coils in molten zinc, a thin layer of zinc is electroplated onto the surface of the steel. Electro-galvanizing provides good corrosion resistance and is commonly used for indoor applications. 3. Powder coating: This process involves applying a dry powder to the surface of the steel coils, which is then heated and cured to form a hard, durable coating. Powder coating provides excellent corrosion resistance and is available in a wide range of colors and finishes. 4. Paint coating: Steel coils can also be coated with a liquid paint, which provides both corrosion resistance and aesthetic appeal. Paint coatings can be applied in various thicknesses and finishes, depending on the desired look and level of protection required. 5. Phosphating: Phosphating is a chemical treatment that involves immersing the steel coils in a phosphate solution. This process creates a thin, adherent layer of phosphate on the surface of the steel, which enhances paint adhesion and improves corrosion resistance. 6. Chromate conversion coating: Also known as chromating or passivation, this process involves immersing the steel coils in a solution containing chromium salts. Chromate conversion coatings provide excellent corrosion resistance and also act as a primer for subsequent paint or powder coating. 7. Zinc-nickel plating: This surface treatment involves electroplating a layer of zinc-nickel alloy onto the steel coils. Zinc-nickel plating provides superior corrosion resistance compared to pure zinc plating and is often used in demanding environments. These are just a few of the many surface treatments available for steel coils. The choice of treatment depends on factors such as the application, desired level of corrosion resistance, aesthetic requirements, and budget. It is important to carefully consider the specific needs of the project and consult with experts to determine the most suitable surface treatment for steel coils.

- Q: Can steel coils be coated with anti-counterfeit materials?

- Yes, steel coils can be coated with anti-counterfeit materials.

- Q: I have a mountain bike w/ 26 wheels. My question is what's the biggest difference between aluminum vs. steel? If most of my riding is off-road, wouldn't the steel wheels be stronger/more durable?

- Aluminum is by far the better choice for wheels, mirageguitarwork is right on the money with his description. One other thing that detracts from steel wheels is that they rust. Wheel builders used to chrome plate them, but all this did was add weight. The wheels would eventually still rust, and this weakens them even more.

Send your message to us

Hot-dip Zinc Coating Steel Building Roof Walls -Good Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords