Hot-dip Zinc Coating Steel Building Roof Walls in Good Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls in Good Price

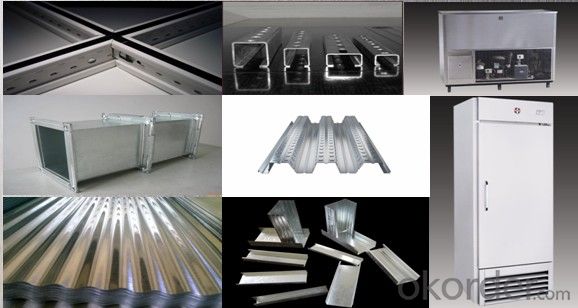

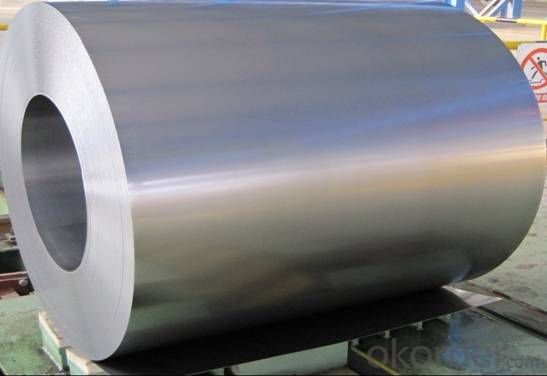

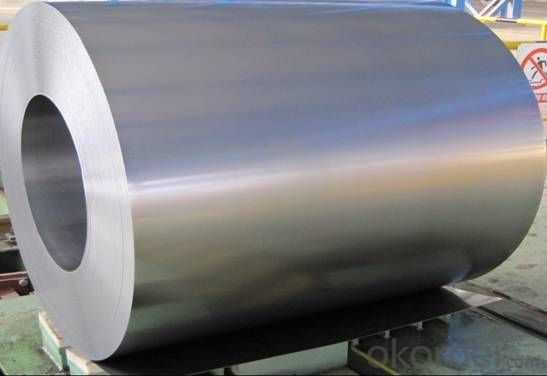

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: I bought this Brinks pad lock and it says boron steel on the lock. I was just wondering what exactly is boron steel and how hard/tough is it?

- Boron steel is rather hard, it is by no means titanium, but certainly better than mild steel. However, as with all metals, hardness is inversely proportional to flexibility, meaning that a good solid whack with a sledge hammer could crack your lock.

- Q: How are steel coils used in various industries?

- Steel coils are used in various industries for their durability and versatility. They are commonly used in automotive, construction, and manufacturing industries for making structures, machinery, and appliances. Steel coils are also utilized in the energy sector for producing power generation equipment and in the transportation industry for making ships and railcars. Overall, steel coils play a significant role in providing strength and reliability in a wide range of industrial applications.

- Q: What is the shelf life of a steel coil?

- The duration for which a steel coil remains usable depends on several factors, including the type of steel, storage conditions, and protective measures implemented. Steel coils can generally be stored for a few months to several years. If a steel coil is stored appropriately in a controlled environment with suitable temperature, humidity, and ventilation, its lifespan can be extended. Moreover, if the coil is coated with protective substances like oil or anti-corrosion coatings, its shelf life can be further prolonged. However, if a steel coil is exposed to unfavorable storage conditions such as high humidity, extreme temperatures, or corrosive substances, its shelf life can significantly decrease. Rust and corrosion can occur due to exposure to moisture and oxygen, leading to a decline in quality and structural integrity. To maximize the shelf life of a steel coil, it is crucial to store it in a well-ventilated, dry area, away from direct sunlight and corrosive substances. Regular inspections and maintenance, including cleaning and reapplication of protective coatings, can also help preserve the coil's quality. Ultimately, it is essential to consult the manufacturer or supplier of the steel coil for specific recommendations regarding shelf life, as different types of steel may have varying levels of durability and specific storage requirements.

- Q: Can steel coils be coated with anti-static materials?

- Yes, steel coils can be coated with anti-static materials to help reduce or eliminate static electricity buildup and discharge. Anti-static coatings are commonly applied to various surfaces, including metals, to prevent damage to sensitive electronic components, improve safety, and enhance overall product performance.

- Q: How are steel coils used in the manufacturing of body reinforcements?

- Steel coils are used in the manufacturing of body reinforcements by being shaped and welded to form sturdy structural components, such as pillars, beams, and frames, that provide strength and rigidity to the vehicle's body structure.

- Q: What are the different types of steel coil finishes used in architectural applications?

- There are several different types of steel coil finishes that are commonly used in architectural applications. These finishes are applied to steel coils to enhance their appearance and provide additional protection against corrosion and weathering. Some of the most popular types of steel coil finishes used in architectural applications include: 1. Mill Finish: This is the most basic type of steel coil finish, where the coil is left untreated after being rolled. It has a dull, gray appearance and is often used in industrial and structural applications where aesthetics are not a primary concern. 2. Hot-Dip Galvanized: In this finish, the steel coil is immersed in a bath of molten zinc, which creates a thick layer of zinc coating on the surface. This finish provides excellent corrosion resistance and is commonly used in outdoor architectural applications such as roofing, gutters, and siding. 3. Galvalume: This finish is similar to hot-dip galvanized, but instead of pure zinc, it uses a combination of zinc and aluminum. Galvalume-coated steel coils offer superior corrosion resistance and are often used in high-end architectural applications, such as metal roofing and wall panels. 4. Pre-Painted: In this finish, a layer of paint is applied to the steel coil before it is shipped to the customer. This allows for a wide range of colors and finishes to be achieved, making it a popular choice for architectural applications where aesthetics are important. Pre-painted steel coils are commonly used in exterior cladding, garage doors, and decorative panels. 5. Stainless Steel: This finish is achieved by using a steel alloy that contains a high percentage of chromium. Stainless steel coils have excellent corrosion resistance and are often used in architectural applications where a clean, modern look is desired, such as handrails, elevator interiors, and kitchen appliances. Each type of steel coil finish offers unique advantages and is suitable for different architectural applications. The choice of finish depends on factors such as the desired appearance, level of corrosion resistance required, and the specific environmental conditions the steel will be exposed to.

- Q: How are steel coils used in the manufacturing of construction equipment?

- Steel coils are used in the manufacturing of construction equipment as they serve as a primary raw material for the fabrication of various structural components such as frames, bodies, and chassis. These coils are typically processed through cutting, bending, welding, and shaping techniques to create the necessary parts that provide strength, durability, and stability to construction machinery.

- Q: How are steel coils used in the manufacturing of machinery?

- Steel coils are commonly used in the manufacturing of machinery as they provide a versatile and reliable raw material. These coils are processed and shaped into various components, such as gears, shafts, and frames, that are essential for the functioning of machinery. The strength and durability of steel make it an ideal choice for withstanding heavy loads and high temperatures, ensuring the longevity and efficiency of machinery in different industries.

- Q: How are steel coils used in the manufacturing of drivetrains?

- Steel coils are used in the manufacturing of drivetrains as they are commonly used to create various components such as gears, shafts, and bearings. These coils are typically processed and shaped into the required forms through cutting, molding, and heat treatment. The steel's strength and durability make it ideal for withstanding the high stresses and forces experienced in drivetrain systems, ensuring reliable and long-lasting performance.

- Q: What are the dimensions of steel coils used in the metal container industry?

- The dimensions of steel coils used in the metal container industry can vary depending on the specific requirements of the industry and the type of container being produced. However, typical dimensions for steel coils used in this industry range from 0.3mm to 3mm in thickness and 600mm to 2000mm in width. The coils are typically wound in a continuous spiral shape, with diameters ranging from 600mm to 1500mm. These dimensions allow for efficient production and handling of the steel coils during the manufacturing process of metal containers.

Send your message to us

Hot-dip Zinc Coating Steel Building Roof Walls in Good Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords