Hot Dip Galvanized Steel Sheets-Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

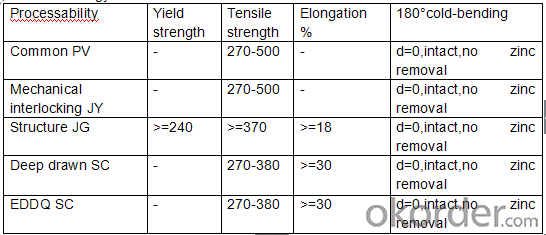

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Can steel sheets be used in marine applications?

- Yes, steel sheets can be used in marine applications. Steel is a common material used for constructing ships, offshore platforms, and other marine structures due to its high strength, durability, and resistance to corrosion in saltwater environments.

- Q: Can steel sheets be used for electrical transformer cores?

- Yes, steel sheets can be used for electrical transformer cores. Steel is a commonly used material for transformer cores due to its magnetic properties, such as its ability to conduct magnetic flux and minimize energy losses. The laminated steel sheets are stacked together to form the core, providing a low reluctance path for the magnetic field and reducing eddy current losses.

- Q: Do the steel sheets have any specific fire ratings?

- Yes, steel sheets often have specific fire ratings due to their inherent fire-resistant properties. These ratings indicate the duration of time the steel sheet can withstand exposure to fire before it loses its structural integrity. The fire ratings are determined through rigorous testing and certification processes.

- Q: What is the difference between a galvanized and stainless steel sheet?

- Both galvanized and stainless steel sheets are utilized in various applications, but there are notable distinctions between the two materials. One significant difference is their resistance to corrosion. Galvanized steel sheets are coated with zinc to shield them from rust and corrosion, making them ideal for outdoor applications or environments with high humidity or moisture. Conversely, stainless steel sheets are composed of chromium and other alloys, granting them superior corrosion resistance. They can endure exposure to chemicals, acids, and saltwater, making them suitable for highly corrosive environments. Another disparity lies in their appearance. Galvanized steel sheets possess a characteristic silver-gray color due to the zinc coating. Over time, the zinc coating can acquire a dull, weathered appearance. In contrast, stainless steel sheets possess a distinct, shiny appearance that can vary based on the applied finish. This makes stainless steel sheets more visually appealing and suitable for applications where aesthetics matter. In terms of strength and durability, stainless steel sheets tend to surpass galvanized steel sheets. Stainless steel has a higher tensile strength, enabling it to withstand more force or pressure before breaking. Additionally, stainless steel is more resistant to dents and scratches compared to galvanized steel. Cost is another factor to consider when choosing between galvanized and stainless steel sheets. Generally, galvanized steel sheets are more cost-effective than stainless steel sheets. This makes them a viable option for applications where corrosion resistance is not of utmost importance. Conversely, stainless steel sheets are pricier due to the higher cost of raw materials and the additional processing required to create the stainless steel alloy. To summarize, the main distinctions between galvanized and stainless steel sheets lie in their corrosion resistance, appearance, strength, and cost. Galvanized steel sheets offer decent corrosion resistance at a lower cost, while stainless steel sheets provide superior corrosion resistance, strength, and a more appealing appearance at a higher price point.

- Q: Are steel sheets resistant to termites or pests?

- Yes, steel sheets are highly resistant to termites and pests.

- Q: What is the thickness tolerance for steel sheets?

- The thickness tolerance for steel sheets can vary depending on the specific grade of steel and the manufacturing process. In general, the industry standard for steel sheet thickness tolerance is typically ±0.005 inches (0.13 mm). However, it is important to note that different applications and industries may have their own specific tolerance requirements. Therefore, it is essential to consult the relevant standards and specifications for the specific steel sheet being used to determine the appropriate thickness tolerance. Additionally, some manufacturers may offer tighter tolerances based on customer requirements or specialized applications.

- Q: How do steel sheets perform in terms of sound insulation?

- Steel sheets have limited sound insulation capabilities. While they can help reduce some high-frequency noise, they are not as effective as other materials specifically designed for soundproofing, such as acoustic panels or soundproofing foams.

- Q: Are steel sheets suitable for cold storage applications?

- Yes, steel sheets are suitable for cold storage applications. Steel is known for its durability, strength, and resistance to extreme temperatures, making it an ideal material for cold storage facilities. It helps maintain a consistent temperature, prevents condensation, and provides excellent insulation, ensuring the quality and freshness of stored goods. Additionally, steel sheets are easy to clean, maintain, and can withstand heavy loads, making them a reliable choice for cold storage applications.

- Q: Can steel sheets be used for elevator manufacturing?

- Indeed, elevator manufacturing can involve the utilization of steel sheets. Owing to its robustness, endurance, and ability to withstand fire and corrosion, steel serves as a frequently employed substance in the construction of elevators. For the fabrication of elevator cabin walls, floors, and doors, steel sheets are commonly employed. In addition, steel finds application in the structural framework and support constituents of the elevator system. The inclusion of steel sheets in elevator manufacturing ensures steadfastness, security, and durability, rendering it a trustworthy option for vertical transportation.

- Q: Are steel sheets suitable for data center infrastructure?

- Yes, steel sheets are suitable for data center infrastructure. Steel is a strong and durable material that can provide the necessary structural integrity and support for data center equipment and systems. It is commonly used for server racks, cabinets, enclosures, and other components within data centers. Steel sheets offer stability, protection, and easy customization options, making them a reliable choice for data center infrastructure.

Send your message to us

Hot Dip Galvanized Steel Sheets-Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords