Hot Dip Galvanized Steel Sheets in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

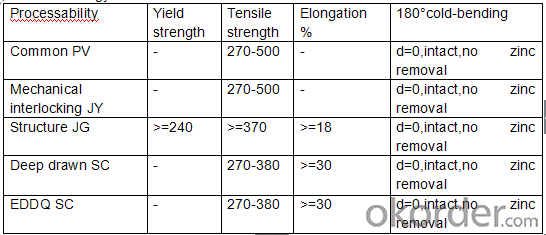

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Can steel sheets be formed into curved shapes?

- Yes, steel sheets can be formed into curved shapes through a process known as cold forming or bending. Cold forming involves applying pressure to the steel sheet to reshape it without heating it. This process can be achieved through various methods such as roll forming, press braking, or stamping. The flexibility of steel allows it to be easily shaped into curves, making it a versatile material for various applications in industries such as construction, automotive, and aerospace.

- Q: How do steel sheets handle static electricity?

- Steel sheets possess excellent electrical conductivity, including the conduction of static electricity. This is due to their high electrical conductivity, allowing them to swiftly eliminate any static charge that accumulates on their surfaces. The effectiveness in handling static electricity is mainly attributed to the presence of unbound electrons within the atomic structure of the steel. When a static charge is applied to a steel sheet, these unbound electrons promptly relocate themselves, nullifying the charge and preventing the accumulation or release of static electricity. Furthermore, steel sheets are frequently coated with a thin protective layer, such as zinc or paint, which further enhances their capacity to dissipate static charges. In general, steel sheets are renowned for their dependable performance in managing static electricity and are commonly utilized in various industrial applications where electrostatic discharge may pose risks to safety or cause damage.

- Q: How is the weight of the steel plate calculated?

- Steel plate by thickness, thin steel plate <4 mm (thinnest 0.2 mm), thick steel plate 4~60 mm, extra thick steel plate 60~115 mm.The steel plate is divided into hot-rolled and cold-rolled parts according to rolling.The width of the sheet is 500~1500 mm; the thickness is 600~3000 mm. According to the type of steel sheet, ordinary steel, stainless steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and industrial pure iron sheet; according to professional use, with drums board, enamel board, bulletproof plate; surface coating and plating, plating with zinc thin plate, tin plate, plating lead sheet, plastic composite plate.

- Q: What is the thermal conductivity of stainless steel sheets?

- The thermal conductivity of stainless steel sheets ranges from approximately 14.4 to 19.0 watts per meter-kelvin (W/m·K), depending on the specific grade and composition of the stainless steel.

- Q: What is the density of steel sheets?

- The density of steel sheets typically ranges from 7.85 to 8.05 grams per cubic centimeter (g/cm³).

- Q: Can steel sheets be used for manufacturing electronics?

- Yes, steel sheets can be used for manufacturing certain electronic components such as chassis and enclosures, as they provide durability and protection. However, they are not commonly used for the internal circuitry or sensitive electronic parts due to their magnetic properties and conductivity limitations compared to other materials like copper or aluminum.

- Q: How do steel sheets compare to wood sheets?

- Steel sheets and wood sheets differ significantly in terms of strength, durability, and usage. To begin with, steel sheets are renowned for their remarkable strength and durability. They can endure heavy loads, extreme weather conditions, and possess high resistance to warping, rotting, and insect damage. Conversely, wood sheets are less sturdy and may succumb to moisture, termites, and decay if not adequately treated or maintained. Regarding versatility, steel sheets offer a wide array of applications. Their high tensile strength and structural stability make them commonly utilized in the construction, automotive, and manufacturing industries. Conversely, wood sheets are commonly employed in interior design, furniture production, and smaller-scale construction projects due to their natural aesthetic appeal and ease of manipulation. Furthermore, steel sheets are fire-resistant, making them a safer option compared to wood sheets, which are combustible and can contribute to the spread of fire. Steel sheets also boast a longer lifespan, necessitating less maintenance and replacement compared to wood sheets, which may require regular refinishing, sealing, or replacement due to wear and tear. Nevertheless, wood sheets possess their own advantages. They are generally more cost-effective than steel sheets, making them a popular choice for projects with budget constraints. Additionally, wood sheets have superior insulation properties, providing natural warmth and soundproofing qualities. Ultimately, the selection between steel sheets and wood sheets hinges on the specific project requirements, encompassing factors such as budget, desired aesthetics, structural needs, and environmental considerations.

- Q: Can steel sheets be painted after installation?

- Yes, steel sheets can be painted after installation. Painting steel sheets after installation is a common practice to enhance their appearance and protect them from rust and corrosion. However, it is important to ensure that the surface is clean and free from any contaminants before applying paint. Proper surface preparation, such as cleaning and sanding, is crucial to promote adhesion and ensure a long-lasting finish. It is also recommended to use a primer specifically designed for steel surfaces before applying the desired paint color. Additionally, selecting a high-quality paint that is suitable for exterior or industrial applications will help to provide the best results and durability.

- Q: What are the different surface patterns available for steel sheets?

- There are several different surface patterns available for steel sheets, including smooth, diamond, textured, and brushed finishes.

- Q: Are steel sheets suitable for electrical transformer cores?

- Yes, steel sheets are suitable for electrical transformer cores. Steel is a commonly used material for transformer cores due to its magnetic properties, high electrical resistivity, and ability to efficiently conduct magnetic flux. It also helps in reducing energy losses and increasing the efficiency of transformers.

Send your message to us

Hot Dip Galvanized Steel Sheets in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords