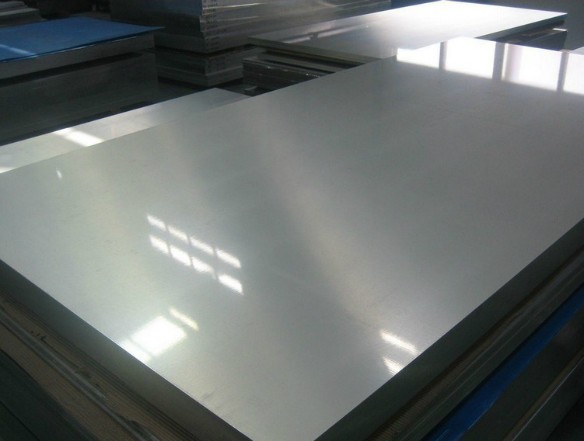

Hot Dip Galvanized Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

General Information of Hot Dip Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specification of Hot Dip Galvanized Steel Coil:

1. Thickness: 0.13mm-0.7mm

2. Width: 600mm-1250mm

3. Zinc Coating: 30-200g/m2

4. Internal Diameter: 508mm/610mm

5. Coil Weight: 3-12MT

6. Quality: commercial and structural quality

7. Surface Treatment: regular & minimum spangle, zero spangle, oiled & dry , chromated , non-skin pass ,skin pass

8. Standard: JIS G 3302, ASTM A 653M, EN 10327

9. Steel Grade: SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD

Technical Data of Hot Dip Galvanized Steel Coil

Chemical Composition | C | Si | Mn | P | S |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Technical Data | |

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Out-of-square | not exceed 1% Flatness |

Bow | 15mmmax |

Edge Wave | 9mmmax |

Centre Buckle | 8mmmax |

Bending At 180 Degree | No crack, purling and fraction |

Application of Hot Dip Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

Package of Hot Dip Galvanized Steel Coil

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips.

- Q: Can steel sheets be used in transportation applications?

- Yes, steel sheets can be used in transportation applications. Steel is a strong and durable material that can withstand the rigors of transportation, making it suitable for various applications such as manufacturing automotive bodies, constructing railway cars, shipping containers, and aircraft parts.

- Q: How do steel sheets handle expansion and contraction?

- Steel sheets handle expansion and contraction by allowing enough flexibility to accommodate changes in temperature. This is achieved through the inherent ductility and elasticity of steel, which enables it to expand and contract without significant deformation or damage. Additionally, steel sheets may be designed with specific expansion joints or gaps to further accommodate thermal changes and prevent buckling or warping.

- Q: What are the common sizes of steel sheets available?

- Common sizes of steel sheets available include 4x8 feet, 4x10 feet, and 5x10 feet. Other sizes may also be available depending on the supplier and specific requirements.

- Q: Can steel sheets be used for walkways or platforms?

- Yes, steel sheets can be used for walkways or platforms. Steel is a durable and strong material, making it suitable for supporting heavy loads and providing a safe surface for walking. It is commonly used in industrial settings, construction sites, and other applications where a sturdy and reliable platform is needed.

- Q: Can steel sheets be used for bulletproof applications?

- Indeed, steel sheets possess the ability to serve in bulletproof capacities. Steel, renowned for its strength and durability, effectively halts bullets from breaching its surface. Industries commonly employ bulletproof steel sheets during the production of armored vehicles, military apparatus, and personal protective equipment, including bulletproof vests and helmets. The bulletproof capabilities of these steel sheets hinge significantly upon their thickness and quality. Manufacturers can tailor the design of steel sheets to withstand an array of ballistic threats, encompassing handguns to high-powered rifles. Moreover, steel's affordability and ease of production render it a favored selection for bulletproof applications across diverse sectors.

- Q: What are the load-bearing properties of steel sheets?

- Steel sheets have excellent load-bearing properties due to their high strength and stiffness. They can withstand heavy loads and distribute them evenly, making them suitable for various structural applications such as building frameworks, bridges, and automotive components.

- Q: Can steel sheets be used for storage cabinets?

- Yes, steel sheets can be used for storage cabinets. Steel is a durable and strong material that is commonly used in storage cabinets due to its ability to withstand heavy loads and resist corrosion. Additionally, steel sheets can be easily molded and welded to create different sizes and shapes of cabinets, making them a versatile choice for storage solutions.

- Q: How do steel sheets perform in low-temperature environments?

- Steel sheets generally perform well in low-temperature environments. The mechanical properties of steel, such as strength and toughness, are not significantly affected by low temperatures. Steel has a low coefficient of thermal expansion, which means it does not contract or expand drastically when subjected to temperature variations. This property allows steel sheets to maintain their shape and structural integrity in cold conditions. Moreover, steel is also highly resistant to brittle fracture at low temperatures. It has a good impact resistance, meaning it can absorb energy without fracturing. This makes steel sheets suitable for applications in low-temperature environments where materials need to withstand heavy loads or sudden impacts, such as in cold storage facilities or offshore structures in Arctic regions. However, it is worth noting that some types of steel, particularly those with high carbon content or low alloy steels, can exhibit reduced toughness and ductility at extremely low temperatures. In such cases, special precautions may be necessary, such as using steel grades specifically designed for low-temperature applications or implementing proper insulation measures to prevent rapid temperature changes. Overall, steel sheets are generally reliable and perform well in low-temperature environments due to their strength, toughness, and resistance to brittle fracture. However, the specific performance of steel in cold conditions may vary depending on the composition and quality of the steel used.

- Q: Are steel sheets suitable for HVAC equipment?

- Yes, steel sheets are suitable for HVAC equipment. Steel is a durable and strong material that can withstand high temperatures, resist corrosion, and provide structural support. It is commonly used in the construction of HVAC systems, such as ductwork, air handlers, and exhaust systems, due to its excellent mechanical properties and ability to meet the demands of the HVAC industry.

- Q: What are the different sheet metal cutting techniques for steel sheets?

- There are several different sheet metal cutting techniques that can be used for steel sheets. Some of the most common methods include shearing, laser cutting, plasma cutting, and waterjet cutting. Shearing involves the use of a mechanical shear to cut the steel sheet along a straight line. Laser cutting uses a high-powered laser beam to melt and vaporize the steel, creating a precise and clean cut. Plasma cutting utilizes a plasma torch to heat and melt the steel, while a high-velocity jet of ionized gas blows the molten metal away. Waterjet cutting involves the use of a high-pressure stream of water mixed with abrasive particles to erode and cut through the steel sheet. Each technique has its own advantages and limitations, depending on factors such as the thickness of the steel, desired precision, and cost considerations.

Send your message to us

Hot Dip Galvanized Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords