Stainless Steel Sheet for Construction Field

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet

Description for Stainless steel Sheet:

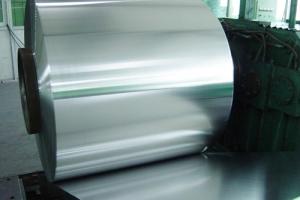

Description | steel sheet,hot rolled steel sheet,cold rolled stainless steel sheet, steel sheet,sheet,steel plate |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420,430,etc. |

Thickness | From 0.3mm to 100mm |

Width | 1000mm,1219mm,1250mm,1500mm,1800mm,2200mm or be cut as your requirement |

Length | 2000mm,2438mm,2500mm,6000mm,6096mm or be cut as your requirement |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Main Features: steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields.

| |

Packaging | By bulk vessel OR By container OR as customers' requirement |

Delivery time | 2-3 weeks after reciept the L/C OR T/T |

Quality | No.1 |

Productivity | 1000 tons/mouth |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Remark | If you have any question,please feel free let us know. |

FAQ:

Why Should You Choose Us?

Profession in construction filed

With full complete production line like steel coil, wire rope, conveyor belt etc

Competitive price, superior quality, strong finance abilty

Strong and Stable qualification

Picture:

- Q: Can steel sheets be used for food processing equipment?

- Steel sheets are indeed capable of being utilized for food processing equipment. People often favor stainless steel for such equipment because of its ability to endure, resist corrosion, and facilitate easy cleaning. Furthermore, stainless steel does not react with food nor does it impart any undesirable flavors or odors. Steel sheets can be molded into various shapes and sizes, rendering them suitable for different kinds of food processing equipment including mixers, conveyors, tanks, and cutting blades. Moreover, stainless steel also possesses resistance to high temperatures, thus making it perfect for applications involving heat. In conclusion, steel sheets are a dependable and sanitary material option for food processing equipment.

- Q: Can steel sheets be used for manufacturing sporting equipment?

- Yes, steel sheets can be used for manufacturing certain types of sporting equipment, such as hockey sticks, cricket bats, or tennis rackets. However, steel sheets are not commonly used for manufacturing sporting equipment as they are heavier and less flexible compared to other materials like carbon fiber or aluminum.

- Q: Are steel sheets suitable for food processing facilities?

- Food processing facilities find steel sheets to be an excellent choice due to their many advantageous qualities. Firstly, steel sheets are non-porous, meaning they do not absorb moisture, bacteria, or odors, resulting in a highly hygienic surface. This prevents bacteria growth and reduces the risk of contamination, ensuring the safety and quality of the processed food. Secondly, steel sheets are easy to clean and maintain. They can withstand frequent cleaning and sanitization without corroding or degrading. Stainless steel, in particular, is resistant to corrosion, rust, and staining, making it ideal for maintaining cleanliness in food processing facilities. Moreover, steel sheets exhibit exceptional durability and strength, guaranteeing their longevity and reliability in food processing operations. They can withstand heavy use, high temperatures, and mechanical stresses commonly encountered in these facilities. Additionally, steel sheets have a high melting point, making them fire-resistant and thereby ensuring the facility's safety. Furthermore, steel sheets offer versatility as they can be fabricated into various shapes and sizes to meet the specific requirements of food processing facilities. They can be used for walls, floors, work surfaces, storage units, and equipment, seamlessly integrating into the facility's infrastructure. In conclusion, steel sheets are highly suitable for food processing facilities due to their hygienic properties, ease of cleaning, durability, and versatility. They contribute to maintaining a safe and sanitary environment, which is crucial for producing high-quality and uncontaminated food products.

- Q: Can steel sheets be used for bulletproof applications?

- Yes, steel sheets can be used for bulletproof applications. Steel is a strong and durable material that can effectively stop bullets from penetrating through it. Bulletproof steel sheets are often used in the manufacturing of armored vehicles, military equipment, and personal protective gear such as bulletproof vests and helmets. The thickness and quality of the steel sheets play a crucial role in determining their bulletproof capabilities. Steel sheets can be designed to withstand different levels of ballistic protection, ranging from handguns to high-powered rifles. Additionally, steel's affordability and ease of production make it a popular choice for bulletproof applications in various industries.

- Q: What are the properties of steel sheets?

- Steel sheets have several advantageous properties, including high strength and durability, excellent corrosion resistance, good thermal conductivity, and the ability to be easily formed and welded.

- Q: Can steel sheets be used for outdoor sculptures?

- Yes, steel sheets can be used for outdoor sculptures. Steel is a durable and weather-resistant material that can withstand outdoor conditions, making it suitable for sculptural installations in outdoor environments. Its strength and versatility allow for various creative possibilities in sculpting outdoor artworks.

- Q: What are the different types of steel alloys used for sheets?

- There are several types of steel alloys commonly used for sheets, including carbon steel, stainless steel, galvanized steel, and alloy steel. Carbon steel is a versatile and widely-used alloy that offers good strength and durability. Stainless steel is highly resistant to corrosion and is often used in applications where hygiene and aesthetics are important. Galvanized steel is coated with a layer of zinc to protect against rusting and is commonly used in outdoor and industrial applications. Alloy steel is a combination of different elements to enhance specific properties such as strength, toughness, and heat resistance.

- Q: Can steel sheets be recycled after their useful life?

- Yes, steel sheets can be easily recycled after their useful life. Steel is one of the most recyclable materials in the world and can be melted down and reused multiple times without losing its properties. Recycling steel sheets not only reduces the need for new steel production but also conserves resources and reduces energy consumption and greenhouse gas emissions.

- Q: What is the process of embossing steel sheets?

- The process of embossing steel sheets involves creating a raised or recessed design on the surface of the steel through the application of pressure. This is typically done using specialized machinery that presses the steel sheet against a patterned die or roller, causing the desired design to be imprinted on the surface. The steel sheet is carefully positioned and aligned with the die, and then pressure is applied to create the embossed pattern. This process can be used to enhance the aesthetic appeal, add texture, or improve the functionality of steel sheets for various applications.

- Q: What is the hardness of the steel sheets?

- The hardness of steel sheets can vary depending on the specific grade and manufacturing process, but generally, steel sheets have a high hardness level due to their strong composition.

Send your message to us

Stainless Steel Sheet for Construction Field

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords