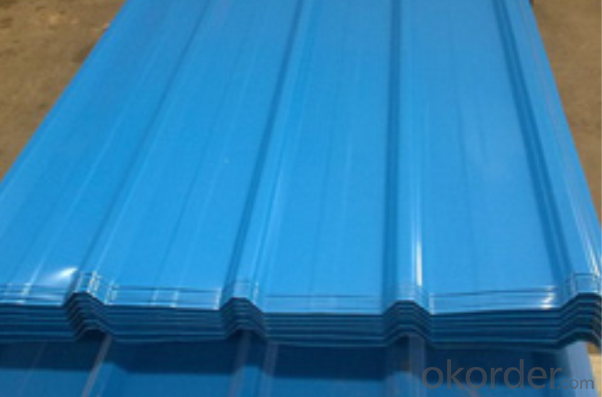

Color Corrugated coated Galvanized Steel sheet With Different Color

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Color Corrugated coated Galvanized Steel sheet With Different Color :

With Gi as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several Layers of color ,then after firing and cooling, finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding ,corrosion resistance

Main Features of Color Corrugated coated Galvanized Steel sheet With Different Color:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

2.Color Corrugated coated Galvanized Steel sheet With Different Color

3. Color Corrugated coated Galvanized Steel sheet With Different Color Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

4.Application for Color Corrugated coated Galvanized Steel sheet With Different Color

sandwich panel roofing, roofing structure, surface of sheet of balcony ,frame of window ,door, door of garage, roller shutter door, booth ,cabana, refrigerated wagon and so on indoor: frame of door, light steel structure of house, sliding door, folding screen ,ceiling ,internal decoration of elevator

5.FAQ of Color Corrugated coated Galvanized Steel sheet With Different Color

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: What are the different types of steel sheet patterns?

- There are several different types of steel sheet patterns commonly used in various industries. Some of the most popular ones include: 1. Plain Steel Sheet: This is the most basic and simple type of steel sheet pattern. It is smooth and does not have any visible texture or pattern. 2. Diamond Pattern Steel Sheet: This type of steel sheet has a diamond-shaped pattern embossed or raised on its surface. It is commonly used for walkways, stair treads, and other applications where slip resistance is important. 3. Perforated Steel Sheet: Perforated steel sheets are made by punching holes in the sheet to create a pattern of openings. These sheets are commonly used for ventilation, filtration, and decorative purposes. 4. Corrugated Steel Sheet: Corrugated steel sheets have a series of parallel ridges and grooves, giving them a wavy appearance. This pattern provides added strength and rigidity, making them suitable for roofing and siding applications. 5. Checkered Steel Sheet: Checkered steel sheets have a pattern of raised squares or rectangles on their surface, similar to a chessboard. They are commonly used for flooring, stairs, and decorative purposes. 6. Hammered Steel Sheet: Hammered steel sheets have a unique texture created by hammering the surface, giving them a rough, rustic appearance. They are often used for decorative purposes and can add a distinct visual appeal to various applications. 7. Brushed Steel Sheet: Brushed steel sheets have a brushed or satin-like finish, achieved by rubbing the surface with an abrasive material. This pattern gives the sheet a smooth, uniform appearance and is commonly used for architectural and decorative applications. These are just a few examples of the different types of steel sheet patterns available. Each pattern has its own unique characteristics and applications, allowing for a wide range of uses in various industries.

- Q: Can steel sheets be used for solar panel structures?

- Yes, steel sheets can be used for solar panel structures. Steel is a durable and strong material that can provide structural support for solar panels. It is commonly used for mounting frames, racking systems, and other components of solar panel structures due to its ability to withstand various weather conditions and provide stability.

- Q: What is the difference between a self-color and painted steel sheet?

- A steel sheet that has not been coated or treated with any additional colors or finishes is referred to as a self-color steel sheet. It maintains the steel surface's natural color and appearance, which is typically a metallic gray or silver. Conversely, a painted steel sheet is one that has been coated with a layer of paint or another protective finish. This coating serves multiple purposes, including enhancing the steel sheet's aesthetic appeal, providing additional protection against rust and corrosion, and increasing its durability. The primary distinction between a self-color and painted steel sheet lies in the presence or absence of a coating. While a self-color sheet preserves the raw and natural appearance of the steel, a painted sheet offers a wide array of color options, enabling customization and harmonization with various design schemes. Furthermore, the existence of a paint or protective coating on a steel sheet provides an extra layer of defense against environmental elements such as moisture, chemicals, and UV rays. This helps prevent the steel from corroding or deteriorating over time, thereby extending its lifespan and ensuring its performance in various applications. To summarize, the main contrast between a self-color and painted steel sheet is the presence or absence of a coating. While a self-color sheet retains the natural appearance of steel, a painted sheet offers added protection, customization options, and aesthetic appeal.

- Q: Can steel sheets be used for walkways or platforms?

- Certainly! Walkways or platforms can be constructed using steel sheets. Steel sheets are frequently employed in industrial and commercial settings owing to their durability, strength, and ability to withstand diverse environmental factors. They can be fabricated and installed to establish robust walkways or platforms capable of enduring heavy pedestrian traffic or the movement of equipment and machinery. Steel sheets can also be customized to fulfill specific design requirements, such as incorporating non-slip surfaces, raised edges for safety, or perforations for drainage. Furthermore, steel sheets necessitate relatively minimal upkeep and can be effortlessly cleaned and maintained, making them a perfect choice for walkways or platforms in various applications, including factories, warehouses, construction sites, and even outdoor areas.

- Q: What is the average price of a steel sheet?

- The average price of a steel sheet can vary depending on various factors such as size, thickness, quality, and market conditions. Therefore, it is difficult to provide an exact average price without specific details.

- Q: What are the common applications of steel sheets?

- Steel sheets are commonly used in a wide range of applications such as automotive manufacturing, construction, infrastructure projects, appliances, shipbuilding, and the production of various metal components.

- Q: What is the aging property of steel plates?

- The aging of steel plate is usually due to the diffusion of carbon atoms and nitrogen atoms in the lattice, forming interstitial atoms, which leads to the solid solution strengthening of the steel plate.

- Q: What's the difference between a spray plate and a colored steel plate?

- Then the color, not the quality of the domestic coatings products, fully meet the demand, the high price of imported coating reduces the competitiveness of skin colour in the plastic film is still dependent on imports, lack of high-grade color coating thickness, functional, high strength, rich color coated plate. Therefore, the choice of color steel plate is relatively narrow, and basically are low-end products, but more convenient, you can buy directly!

- Q: What is the average weight of a steel sheet?

- The weight of a steel sheet can differ based on its dimensions, thickness, and type of steel utilized. Nevertheless, as a general rule, a typical steel sheet measuring 1m by 1m and with a thickness of 1mm usually weighs approximately 7.85 kilograms. It is crucial to recognize that this estimation is only an approximation, and the actual weight may fluctuate depending on the precise attributes of the steel sheet. For a precise weight, it is advisable to seek advice from the manufacturer or consult the specifications of the steel sheet.

- Q: What is the width of carbon steel coil and the width of stainless steel coil, one is 1250 and the other is 1219?

- But the technical content of carbon steel with stainless steel is different, our country in more than 10 years ago the ability of continuous rolling of stainless steel is not high, equipment are imported, the stainless steel mill is dominated by 1219-1300, but also the development of national wide stainless steel 1500-2050, but the price is expensive at least thousands of dollars a ton, after all put the equipment to recover the cost, and the number of business orders is not much, it is difficult to find a spot on the market. Carbon steel countries have developed for many years, technology and equipment are mature, so the market has 1250 as production standards.

Send your message to us

Color Corrugated coated Galvanized Steel sheet With Different Color

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords