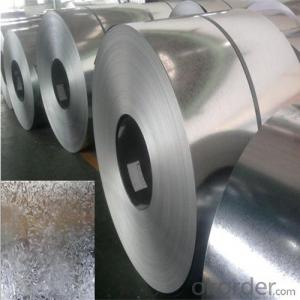

HOT-DIP GALVANIZED STEEL COIL WITH HIGH QUALITY NO.1

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details | |||||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | Brand Name: | N/M | Model Number: | ssp-226 | |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet | ||

Packaging & Delivery | |||||

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D / S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.Packaging Details:

Standard export package.

Other types of packing can be customized as per client's requirements.

- Q: What are the dimensions of steel coils used in the appliance industry?

- Steel coils used in the appliance industry can have varying dimensions depending on the specific application and requirements. However, a typical range for these coils is a thickness of 0.015 to 0.035 inches (0.38 to 0.89 millimeters), a width of 24 to 36 inches (61 to 91 centimeters), and a weight between 1,500 to 10,000 pounds (680 to 4,535 kilograms). These dimensions are chosen to facilitate efficient handling, transportation, and processing during the appliance manufacturing process. It is important to verify these dimensions with the manufacturer or supplier for accurate and current information.

- Q: Is steel with a black coloring as strong as regular steel. if you are asking why i have two wordsBlack Katana.I know a katana is not made with normal steel, it is made of two types with varying grades of carbon to give it speacial properties, i just want to know if the black will make a difference.

- There are many types of steel some very rigid, while you can have steel that is very flexible. The type of katana: steel is for Samurai swords

- Q: Are steel buildings more durable than concrete building?

- Metal buildings are very cost-effective and costs less than a concrete or a wooden building. Steel prices are quite stable as compared to wood or concrete prices which are constantly rising.

- Q: How are steel coils protected against fire and heat?

- Steel coils are protected against fire and heat through a variety of methods to ensure their safety. One of the primary ways to safeguard steel coils is by applying a fire-resistant coating. These coatings are designed to provide a barrier between the steel surface and the heat source, preventing direct contact and reducing the risk of ignition or damage. In addition to coatings, steel coils can also be stored in fire-resistant warehouses or storage facilities. These structures are constructed using materials that are resistant to fire, such as concrete or steel, and are equipped with fire suppression systems like sprinklers or fire extinguishers. These measures help to contain and suppress any potential fire, limiting its spread and protecting the steel coils. Furthermore, fire safety protocols and procedures are often implemented in facilities that handle steel coils. These may include regular fire drills, training programs for employees on fire prevention and response, and the presence of fire safety equipment like fire alarms and fire hoses. These measures ensure that any fire incidents can be promptly detected and addressed, minimizing the risk to the steel coils. Overall, the protection of steel coils against fire and heat involves a combination of fire-resistant coatings, proper storage in fire-resistant structures, and the implementation of fire safety protocols. These measures work together to mitigate the risk of fire and heat-related damage to the steel coils, ensuring their integrity and safety.

- Q: What are the different types of welding methods used for steel coils?

- There are several different types of welding methods commonly used for steel coils, including spot welding, seam welding, and flash butt welding. Spot welding involves applying heat and pressure to two overlapping pieces of metal to create a strong bond. Seam welding is similar to spot welding but is used for continuous welds along the length of the coil. Flash butt welding involves using an electric current to create a heat source between two ends of the coil, which are then pressed together to form a solid weld. These methods allow for efficient and effective joining of steel coils in various industrial applications.

- Q: Can steel coils be coated with anti-graffiti materials?

- Yes, steel coils can be coated with anti-graffiti materials.

- Q: Also, what is the top best slow cooker that is 100% stainless steel? Thank you!

- My SS pans are Prestige.

- Q: How do steel coils impact the overall cost of production?

- Steel coils have a significant impact on the overall cost of production in a variety of industries. Firstly, the cost of steel coils themselves can be a significant expense. The price of steel is influenced by various factors such as supply and demand, raw material costs, and market fluctuations. Any increase in the cost of steel coils can directly impact the overall production cost, as it becomes a major component in the manufacturing process. Moreover, steel coils also affect the operational costs of production. They are typically used in various manufacturing processes, such as stamping, rolling, and forming, which require specialized machinery. The durability, quality, and size of the steel coils play a vital role in determining the efficiency and effectiveness of these processes. If the steel coils are of low quality or not suitable for the specific production requirements, it can lead to increased downtime, machinery maintenance, and rework, all of which contribute to higher production costs. In addition, transportation costs associated with steel coils can also impact the overall cost of production. Steel coils are usually heavy and bulky, necessitating special handling and transportation arrangements. The distance between the supplier and the production facility, as well as the mode of transportation, can significantly influence the logistics costs. Any increase in transportation expenses, such as fuel prices or shipping fees, can directly impact the overall cost of production. Lastly, the availability of steel coils can also impact production costs. In times of high demand or limited supply, the price of steel coils may increase, leading to higher production costs. Furthermore, if there is a shortage of steel coils due to factors like trade restrictions or disruptions in the supply chain, manufacturers may have to resort to alternative materials or sources, which could be more expensive or lower in quality. These factors can have a cascading effect on the overall cost of production. Overall, steel coils have a significant impact on the overall cost of production. Their cost, quality, transportation, and availability all influence the efficiency, effectiveness, and affordability of the manufacturing process. Therefore, manufacturers need to carefully consider and manage these factors to optimize their production costs and maintain competitiveness in their respective industries.

- Q: How are steel coils used in the manufacturing of railway bridges?

- Steel coils are used in the manufacturing of railway bridges as they are transformed into structural components such as beams, plates, and girders. These coils are processed and shaped into the desired forms, providing the necessary strength and durability for the bridge's construction.

- Q: What are the common coil storage conditions?

- The common coil storage conditions include keeping the coils in a dry and well-ventilated area, away from direct sunlight and extreme temperatures. It is also important to store the coils in an upright position, on pallets or racks, to prevent damage and ensure easy access for handling and transportation.

Send your message to us

HOT-DIP GALVANIZED STEEL COIL WITH HIGH QUALITY NO.1

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords