Hot Dipped Galvanized Steel Coil China Factory Price DX51 DZ100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Hot Dipped Galvanized Steel Coil DX51 DZ100 :

Plain galvanized sheets are used for automotive body building, panels, electrical appliances like refrigerator, washing machine, and use for advertisement panels. Etc.

The use of galvanized sheets improves paint ability and corrosion resistance and aesthetic looks.

We provide our customers with an assortment of corrugated sheets, galvanized corrugated sheets and galvanized plain sheets. These sheets are manufactured using premium quality material which provides high tensile strength and makes them seepage resistant. GC sheets prove to be a cost effective solution for various construction purposes such as roofing, side-walls, partitions and panels.

2.Main features of Hot Dipped Galvanized Steel Coil DX51 DZ100:

With excellent cold-rolling steel strips as a base material, it has the advantages of

.Not easily rust; acid resistance and corrosion resistance;

.Widely used in light and heavy industry, food making, architecture, shipping, paper and medicine industry;

.Large and stable supply capability;

.Prompt delivery and rich experience in exporting.

3.Hot Dipped Galvanized Steel Coil DX51 DZ100 Images:

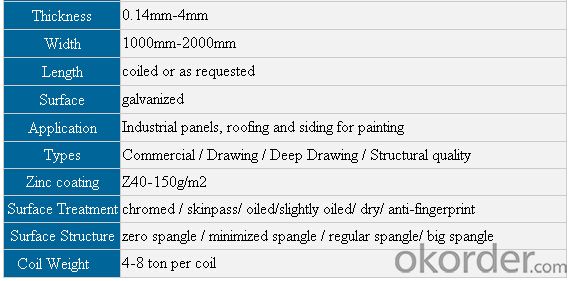

4.Hot Dipped Galvanized Steel Coils for Roofing Sheet -standard Specification:

5.Production Process

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel coil packaging techniques?

- In the industry, there are various steel coil packaging techniques commonly used. These techniques aim to safeguard the steel coils throughout storage, transportation, and handling, ensuring their arrival in excellent condition. One technique utilized is called "eye-to-the-sky" packaging, where the steel coils are vertically stacked with the coil's eye facing upward. They are then secured using steel strapping or banding. This method is commonly employed for smaller coils and effectively shields against damage caused by handling and transportation. Another typical packaging technique is "eye-to-the-wall" packaging. Here, the steel coils are horizontally stacked with the coil's eye facing the wall. They are also secured using steel strapping or banding. This particular method is often used for larger coils and provides enhanced stability during transportation. "Shrink-wrapping" is a third packaging technique wherein the steel coils are tightly wrapped in plastic shrink-wrap material. This offers protection against moisture, dust, and other contaminants. Shrink-wrapping is especially useful when steel coils need to be stored or transported outdoors or in harsh environments. Moreover, certain steel coil packaging techniques involve the usage of wooden pallets or skids. The coils are placed on these pallets or skids, which provide a stable base and enable easy handling using forklifts or other equipment. Additionally, the coils can be secured to the pallets or skids using steel strapping or banding. Ultimately, the selection of a steel coil packaging technique depends on factors like coil size, transportation requirements, and environmental conditions. By choosing the appropriate packaging technique, steel coils can be adequately protected and delivered to their destination without any damage or deterioration.

- Q: Suppose you made a sword out of diamond (just follow me here, it's only theoretical). Would it be lighter than a sword of the same size made out of steel?

- The weight of steel is dependent among what kind of steel, shape, length, width, thickness a 5mm by 5mm ball of carbon steel would wiegh 1.69969 g a same size diamond weighs .79 carats equivelent to 1.5 grams So the basic answer is, yes, diamond is lighter than steel, but barely

- Q: How does coil slitting work?

- Coil slitting is a process used in manufacturing industries to cut large coils of material, such as metal, into narrower strips of desired widths. The coil is unwound and passed through a set of circular blades that make precise cuts along the length of the coil. The blades can be adjusted to the desired width, and the process continues until the entire coil is slit into multiple smaller coils or strips.

- Q: basically all the info you can find about s1 tool steel i found a bunch about annealing, and hardening, tinsel strength and stuff like that but i need MORE!!!!!

- S1 Tool Steel

- Q: What are the different methods of slitting steel coils?

- There are several methods of slitting steel coils, including rotary slitting, wobble slitting, and crush cutting. Rotary slitting involves using circular knives to cut through the steel coil, while wobble slitting uses a wobbling blade that moves from side to side. Crush cutting, on the other hand, involves crushing the steel coil between two rotating blades to create a clean cut. These methods offer different advantages and are chosen based on the specific requirements of the steel coil slitting process.

- Q: i am looking for an exact process of how to forge damascus steel.any tips or pointers and web sites or tutoreals will be helpfull.

- hand made folding knife English tip, blade of Damascus metallic sort Rose, 2,5mm thickness, no liners, teja spring embellished by using metallic report and billet surrounded of chrome metallic. A Damascus blade knife is characterised by using a wavy, mottled visual allure on the blade that’s led to by using the approach used to shape the metallic. the technique of transforming into Damascus metallic is derived from a centuries-previous forging technique used to create blades that grew to become very just about mythical of their attractiveness for power and sharpness it exchange into reported a Damascus knife ought to shrink with the aid of a rifle barrel to boot as with the aid of a hair falling on the blade.

- Q: How are steel coils used in the production of industrial valves?

- Steel coils are used in the production of industrial valves as they are typically cut and formed into various components, such as valve bodies and stems. The coils provide a strong and durable material for the valves, ensuring their reliability and longevity in industrial applications.

- Q: Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- Combat steel? No such thing... Combat steel is a commercial product... not a true type of steel, since there is no ASTM grade of combat steel... And carbon steel is a WHOLE list of different types of steel, whether it's tempered or not... The company does not provide what steel specifications it has other than combat steel... So my best guess is that it's an alloy of 1095 or 301 spring tempered... both are resilient to snapping and fatigue, and common in modern swords... however, they do not hold an edge very well and are prone to rusting...

- Q: i mean the properties include the elasticity, impact load and ductility. am doing assignment about the perfect material that should be possessed by spring and i found alloy steel is the perfect and am confused whether stainless steel is the same with alloy steel ?

- Alloy steel is a stainless steel. The differences between the two are the composition of the metal. Alloy steel is steel with usually less than 5% of other elements, like molybdenum, copper, chrome while stainless steel is a steel with at least 10-11% of chromium.

- Q: How are steel coils used in the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems as they serve as the primary heat transfer component. The coils are designed to efficiently transfer heat between the air and refrigerant, allowing for effective cooling or heating of the space.

Send your message to us

Hot Dipped Galvanized Steel Coil China Factory Price DX51 DZ100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords