PP Woven Geotextile for Road and Highway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of PP Woven Geotextile for Construction

1) Weight / Mass: 75g/m2-800g/m2 .

2) Width: Within 8 m (1m-8m).

3) Length: 50m-100m/roll (as request).

4) Material: PP/PET.

5) Color: Black , white , grey, others

6) Certificate: CE/ISO9001, ISO14001 .

7) Manufacturing method: nonwoven / woven.

8) The equipment is introduced from Germany.

9) This geotextile can be made of polypropylene (PP), or polyester (PET), Polyvinyl or synthetic fiber on needle punch machine.

10) The mass is available from 75g/m² to 800g/m² and the width available from 1.0m-8m, monolayer or multilayer (reinforcement geotextiles), long fiber or short fiber.

11) Color: all kinds of color are available. The annual production ability is 10 million square meters.

12) The fabric can also be heat treated by infrared at customer's requirements. Our geotextile are UV stabilized to give protection against aging under exposure to natural ultra-violet light.

2. Introduction of PP Woven Geotextile for Construction

Geotextiles are composed from synthetic polypropylene/polyester fibres through a mechanical process of needling the fabric and adding, when necessary, a thermo fused process, resulting in a uniform porous structure with excellent tensile strength and chemical deterioration. Type: 1. Wovens & knitted: use various fibre types (e.g. monofilament, multi-filament, split extruded film) in different combinations. 2. Non-wovens: staple or continuous fibres that are heat treated or needlepunched to “fix” fibres relative to each other.

RFQ:

What is the main application of PP Woven Geotextile for Construction?

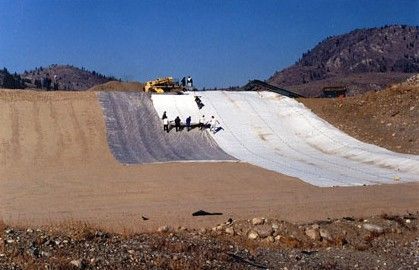

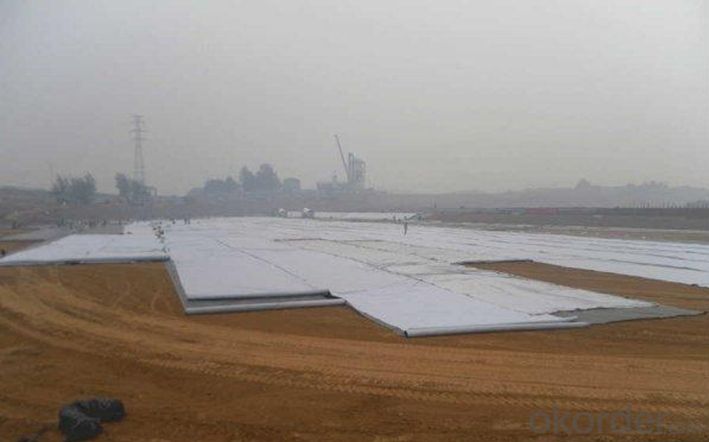

The main application of our Short Fiber Nonwoven Geotextile is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for PP Woven Geotextile for Construction?

One of the largest manufacturer of PP Woven Geotextile for Construction

with advanced equipment, big production capacity and excellent quality.

- Q: What are the different installation guidelines for geotextiles in reinforcement projects?

- The installation guidelines for geotextiles in reinforcement projects typically involve the following steps: 1. Site Preparation: Clear the construction area of any vegetation, debris, or loose soil. Level the ground and remove any protrusions or sharp objects that could damage the geotextile. 2. Geotextile Placement: Unroll the geotextile over the prepared area, ensuring it covers the entire project site. Overlaps between adjacent rolls should be at least 1 to 2 feet to provide proper continuity. 3. Anchoring: Secure the geotextile at the edges using anchor trenches, stakes, or other appropriate methods to prevent movement during installation or in the long term. 4. Jointing: Overlap adjacent geotextile panels by a minimum of 1 to 2 feet, depending on the project requirements. Secure the overlap with appropriate fasteners or adhesives to ensure proper functioning. 5. Protection: If necessary, cover the geotextile with a protective layer, such as a layer of soil or aggregate, to shield it from potential damage during construction activities or exposure to UV radiation. 6. Compaction: If the project involves soil stabilization or reinforcement, follow the recommended compaction procedures to ensure proper integration of the geotextile with the surrounding soil or aggregate. 7. Quality Control: Regularly inspect the geotextile installation to ensure that it is properly placed, free of damage, and functioning as intended. Any identified issues should be addressed promptly. It is important to note that specific installation guidelines may vary depending on the project type, site conditions, and the type of geotextile being used. It is recommended to consult the manufacturer's recommendations and seek professional guidance to ensure proper installation.

- Q: What are the advantages of using geotextiles in shoreline stabilization projects?

- There are several advantages of using geotextiles in shoreline stabilization projects. Firstly, geotextiles provide effective erosion control by preventing the loss of sediments and soil particles from the shoreline. This helps to maintain the stability and integrity of the shoreline, reducing the risk of damage to nearby infrastructure and habitats. Secondly, geotextiles act as a filter, allowing water to pass through while retaining soil particles. This helps to improve water quality by reducing sediment runoff and the associated pollution. Additionally, geotextiles are durable and long-lasting, making them a cost-effective solution for shoreline stabilization. They are resistant to degradation from UV exposure, chemicals, and biological factors, ensuring their effectiveness over an extended period. Furthermore, geotextiles are flexible and easy to install, making them suitable for a variety of shoreline environments. They can be customized to fit specific project requirements, providing a versatile option for different shoreline stabilization needs. Overall, the use of geotextiles in shoreline stabilization projects offers numerous advantages, including erosion control, improved water quality, cost-effectiveness, durability, and ease of installation.

- Q: What are the specifications for geotextiles used in transportation projects?

- The specifications for geotextiles used in transportation projects generally include criteria such as tensile strength, puncture resistance, thickness, permeability, and durability. These specifications ensure the geotextiles can effectively separate, reinforce, and filter materials in road construction, preventing the mixing of soil layers, enhancing stability, and improving drainage.

- Q: How are geotextiles used in construction?

- Geotextiles are used in construction as a versatile material that provides various benefits such as erosion control, soil stabilization, filtration, and drainage. They are commonly used in road construction, retaining walls, embankments, and landfills to separate different soil layers, reinforce weak soils, and prevent the migration of fine particles. Geotextiles are also used in coastal and riverbank protection, as well as in construction projects that require soil reinforcement and increased durability.

- Q: What is the purpose of using geotextiles in construction projects?

- The purpose of using geotextiles in construction projects is to enhance soil stability, reinforce weak soil, improve drainage, prevent soil erosion, and provide separation and filtration between different soil layers or materials.

- Q: What is the use of the black network when the shop is paved?

- It is geogrid, can enhance the overall strength of the roadbed, from the role of tensile, mostly polyethylene materials.

- Q: Consult geotextile and geomembrane is not the same thing?

- Geomembrane completely soiled geotextile is to keep the wet state of water will evaporate

- Q: How do geotextiles improve the stability of slopes?

- Geotextiles improve slope stability by providing reinforcement and erosion control. They are placed within the slope to act as a barrier against soil movement, preventing erosion and enhancing the overall stability of the slope. Additionally, geotextiles help to distribute loads more evenly, reducing the potential for slope failure.

- Q: Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

Send your message to us

PP Woven Geotextile for Road and Highway Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords