Tencate Mirafi HDPE Uniaxial Geogrids with High Tensile Strength for Retaining Wall/Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 12000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Uniaxial Geogrid with High Tensile Strength for Retaining Wall/Road Consturction

1. Main Introduction of HDPE Uniaxial Geogrid with High Tensile Strength for Retaining Wall/Road Consturction

In grade separation applications, Uniaxial Geogrids are used to help soils stand at virtually any desired angle; from 0 to 90 degrees. Geogrids can be combined with a wide variety of facing elements in retaining wall and slope applications to produce the desired structural or aesthetic conditions for any project.

Geogrid Reinforced Soil Retaining Walls:

Geogrid reinforced soil retaining walls offer economical and aesthetically pleasing alternatives to conventional retaining wall systems. The geogrid reinforced fill zone behind the wall facing acts as a uniform mass or block, providing stability to the wall and structure. Geogrids work with a wide variety of fill materials and facing elements including segmental concrete blocks, concrete panels, geogrid wraps, timbers or boulders.

Geogrid Reinforced Slopes:

Geogrid reinforced slopes provide a natural and economical alternative to conventional concrete retaining walls. Geogrid reinforced slopes create naturally finished slope structures that are easy to construct and enhance property values because of their natural beauty. Geogrid reinforced slopes can be built at any angle to provide the most economical use of available space while avoiding the increased cost of vertical structures.

The construction of embankments, bridge approach fills, dikes and causeways over soft soils and wetlands traditionally involves expensive, time consuming construction methods. Geogrid reinforcement of these structures minimizes the project footprint, fill requirements and differential settlement, saving time and money

2. Specifications and Technical Data of HDPE Uniaxial Geogrid with High Tensile Strength for Retaining Wall/Road Consturction

No. | Index properties | Test Method | Item(PEUG) | ||||||

60 | 80 | 120 | 160 | 180 | 200 | ||||

1 | Polymer | _ | HDPE | ||||||

2 | Minimum Carbon Black % | ASTM D4218 | 2 | ||||||

3 | Tensile Strength @ 2% Strain MD kN/m | ASTM D6637 | 16 | 23 | 35 | 47 | 52 | 58 | |

4 | Tensile Strength @ 5% Strain MD kN/m | 31 | 44 | 65 | 85 | 104 | 116 | ||

5 | Ultimate Tensile Strength MD kN/m | 60 | 80 | 120 | 160 | 180 | 200 | ||

6 | Strain @ Ultimate Strength % | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 | ||

7 | Junction Efficiency % | GRI GG2-87 | 93 | 93 | 93 | 93 | 90 | 90 | |

8 | Flexural Rigidity mg-cm | ASTM D1388 | 1,400,000 | 2,300,000 | 7,700,000 | 19,000,000 | _ | _ | |

Durability | |||||||||

9 | UV Resistance % | ASTM D4355 | 98 | 98 | 98 | 98 | 98 | 98 | |

10 | Oxidation Resistance % | EN ISO 13438 | 100 | 100 | 100 | 100 | 100 | 100 | |

11 | Brittleness | WashDOT T926 | Pass | Pass | Pass | Pass | Pass | Pass | |

Reduction Factor | |||||||||

12 | Minimum Reduction Factor for | ASTM D5262 | 1 | _ | 1.02 | 1 | _ | _ | |

13 | Reduction Factor for Creep for | ASTM D5818 | 2.23 | 2.23 | 2.23 | 2.23 | 2.23 | 2.23 | |

Dimensions | |||||||||

14 | Roll Width m | _ | 1 | 1 | 1 | 1 | 1 | 1 | |

15 | Roll Length m | _ | 75 | 50 | 30 | 30 | 30 | 30 | |

16 | Roll Weight kg | _ | 30 | 27 | 23 | 29 | 33 | 36 | |

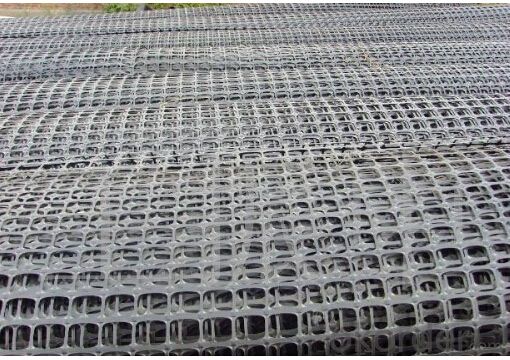

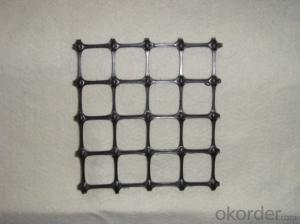

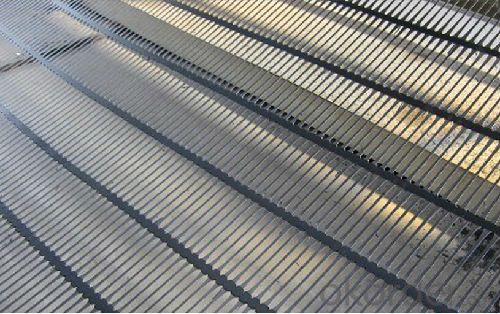

3. Some Photos of HDPE Uniaxial Geogrid with High Tensile Strength for Retaining Wall/Road Consturction

FAQ:

1. What's your payment terms?

T/T, L/C at sight

2. What's your delivery time?

Within 15days against deposit received

3/ What's your package?

WOVEN BAGS

- Q: How do geogrids help in reducing construction labor requirements?

- Geogrids help in reducing construction labor requirements by providing reinforcement and stability to the soil, which eliminates the need for excessive excavation, backfilling, and compaction. This saves time and effort for the construction workers, as geogrids can bear heavy loads and prevent soil movement, reducing the need for extensive manual labor.

- Q: Can geogrids be used in slope stabilization for railway embankments with high water table conditions?

- Yes, geogrids can be used in slope stabilization for railway embankments with high water table conditions. Geogrids are commonly used in such scenarios to reinforce the soil and prevent slope failure. They can improve the stability of the embankment by increasing the bearing capacity and reducing water infiltration, thus mitigating the adverse effects of high water table conditions.

- Q: Can geogrids be used in green roof applications?

- Yes, geogrids can be used in green roof applications. Geogrids provide reinforcement and stability to the green roof system, helping to prevent soil erosion and retain water. They can help distribute the load of the green roof evenly, ensuring structural integrity and longevity.

- Q: How much is the tensile strength of Geogrid

- Solder paste type: 200KN or less.

- Q: Can geogrids be used in agricultural applications?

- Yes, geogrids can be used in agricultural applications. They can provide soil stabilization and erosion control, improve load-bearing capacity for heavy equipment, and enhance drainage in agricultural fields. Geogrids can also help prevent soil compaction and improve crop yield by reducing soil erosion and providing a stable growing environment.

- Q: How to fill in the geogrid evaluation form

- Detection method and frequency in accordance with the requirements, the other reference to your command requirements!

- Q: How is a geogrid different from other geosynthetic materials?

- A geogrid is a type of geosynthetic material that is specifically designed to provide structural reinforcement and stabilization to soil and other materials. Unlike other geosynthetic materials such as geotextiles or geomembranes, which are primarily used for filtration, separation, or containment purposes, geogrids are characterized by their high tensile strength and open-grid structure. This unique design allows geogrids to effectively distribute loads and confine soil particles, improving the overall stability and performance of the soil or aggregate.

- Q: Are geogrids suitable for use in railway ballast reinforcement?

- Yes, geogrids are suitable for use in railway ballast reinforcement. Geogrids provide stabilization and reinforcement to the ballast layer, improving its strength and preventing deformation under heavy loads. They distribute the load more evenly, reducing the risk of settlement and track misalignment. Additionally, geogrids enhance the overall performance and longevity of the railway track by minimizing maintenance and repair needs.

- Q: Where is the best geogrid to do?

- Plastic grille mold Huangyan Xuan Ya mold to do very good, the price is also very suitable!

- Q: Geogrid construction must be folded back 2m wrapped in compacted packing

- Stop all construction vehicles and construction machinery driving or parking on the paved geogrid, check the quality of geogrid construction, found folded, puncture, tear and damage, depending on the extent of repair or replacement.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Tencate Mirafi HDPE Uniaxial Geogrids with High Tensile Strength for Retaining Wall/Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 12000 Square Meters Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords