High Temperature Thermal Insulation Texturized Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Texturized glass fiber cloth is a soft, flexible cloth manufactured from continuous filament texturized yarns. It is an ideal replacement for asbestos product used for thermal insulation and heat protection. It has low coefficient of thermal expansion and is suitable for temperature up to 550℃

Features: Excellent insulation property, High working temperature 550℃, Tight yarn construction, High strength and abrasive

Application: Insulation blanket, Insulation jacket, Further processing

PRICE: USD2 per square meter

UNIT: square meter

MOQ: 500square meters

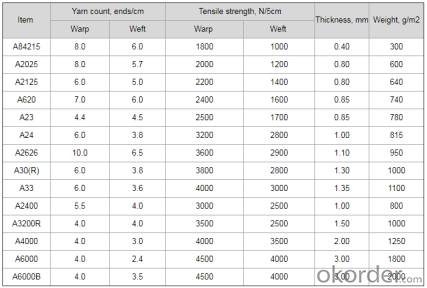

Weight: 300gsm-2000gsm

Thickness: 0.4mm-3mm

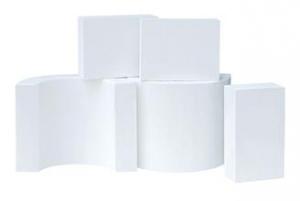

Roll length: customized

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Is fiberglass fabric resistant to oil and grease?

- Yes, fiberglass fabric is generally resistant to oil and grease. Fiberglass has excellent chemical resistance properties, making it highly resistant to a wide range of oils and greases. This resistance is due to the non-reactive nature of fiberglass, which prevents the fabric from being degraded or damaged by contact with oil and grease. Additionally, fiberglass fabric is also resistant to many other chemicals, including acids, alkalis, and solvents, making it a versatile material in various industries where resistance to oil and grease is required. However, it is important to note that the level of resistance may vary depending on the specific type and quality of fiberglass fabric used. It is always recommended to consult the manufacturer or supplier for specific information on the resistance capabilities of the fiberglass fabric in question.

- Q: Silicone rubber and glass fiber cloth, capable of curing 300 degrees of adhesion method?

- 250--320 degrees Celsius can be achieved between high temperature silicone fiber cloth.Silicone bonding can be used.

- Q: Are fiberglass fabrics resistant to oil or grease?

- Yes, fiberglass fabrics are generally resistant to oil and grease.

- Q: What are the different finishing options available for fiberglass fabric?

- There are several different finishing options available for fiberglass fabric, each with its own unique properties and uses. One common finishing option is coating the fiberglass fabric with a resin or polymer. This helps to enhance the fabric's strength and durability, making it more resistant to tears and abrasion. The coating can also provide added protection against chemicals, UV rays, and moisture. Another finishing option is laminating the fiberglass fabric with other materials, such as foam or felt. This creates a composite fabric that combines the strength and flexibility of the fiberglass with the added properties of the laminated material. This can be useful for applications where insulation, cushioning, or sound absorption is required. Additionally, fiberglass fabric can be treated with a fire retardant finish. This coating helps to reduce the fabric's flammability and can make it suitable for use in environments where fire safety is a concern. Some fiberglass fabrics are also available with a silicone or PTFE (polytetrafluoroethylene) finish. These finishes provide the fabric with enhanced heat resistance, as well as a non-stick surface that is easy to clean. This makes them ideal for applications such as insulation blankets, conveyor belts, or release liners. In summary, the different finishing options available for fiberglass fabric include resin or polymer coatings, lamination with other materials, fire retardant treatments, and silicone or PTFE finishes. The choice of finishing option will depend on the specific requirements of the application, such as strength, durability, heat resistance, or fire safety.

- Q: Can fiberglass fabric be used for filtration in water treatment plants?

- Yes, fiberglass fabric can be used for filtration in water treatment plants. Fiberglass fabric is known for its high strength, durability, and resistance to chemicals, making it a suitable material for filtration applications. It can effectively remove suspended solids, sediment, and other particulate matter from water, ensuring a cleaner and safer water supply. Additionally, fiberglass fabric can withstand high temperatures and pressures, making it suitable for various filtration processes used in water treatment plants.

- Q: How does fiberglass fabric compare to other fabric materials in terms of cost?

- Fiberglass fabric tends to be more expensive compared to other fabric materials.

- Q: Is fiberglass fabric resistant to birds?

- Fiberglass fabric does not possess natural resistance to birds. Despite being a robust and enduring substance, birds can still inflict harm upon it. They have the tendency to peck at or scratch its surface, leading to slight to moderate impairment. Furthermore, if fiberglass fabric meets their requirements, birds might employ it as a construction material for their nests. Nevertheless, fiberglass fabric is not the preferred choice for birds due to its lack of suppleness and flexibility, qualities typically sought after for nesting. Consequently, while it may not be entirely impervious to birds, fiberglass fabric is less likely to be heavily targeted or extensively damaged by them in comparison to other materials.

- Q: Is fiberglass fabric resistant to chemicals in automotive fluids?

- Yes, fiberglass fabric is generally resistant to chemicals found in automotive fluids. Fiberglass itself is a highly durable and versatile material that is known for its resistance to a wide range of chemicals, including those typically found in automotive fluids such as gasoline, diesel, oil, and antifreeze. It is commonly used in automotive applications where resistance to chemicals is required, such as in the production of gaskets, seals, and insulation materials. However, it is important to note that the specific chemical resistance of fiberglass fabric can vary depending on the type of resin used in its production and the specific composition of the automotive fluid. Therefore, it is always recommended to consult the manufacturer's specifications or conduct compatibility tests to ensure the optimal performance of fiberglass fabric in contact with automotive fluids.

- Q: Can fiberglass fabric be used for insulation sheets?

- Yes, fiberglass fabric can be used for insulation sheets.

- Q: What is the moisture resistance of fiberglass fabric?

- Fiberglass fabric has high moisture resistance due to its inherent non-absorbent nature and the hydrophobic properties of the fiberglass material.

Send your message to us

High Temperature Thermal Insulation Texturized Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords