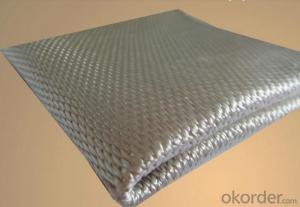

High Temperature Insulation Kevlar Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRICE: USD10 per square meter

UNIT: square meter

MOQ: 500 square meter

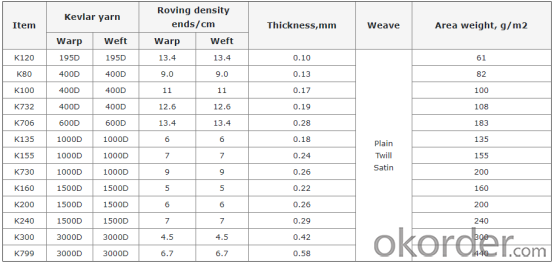

Weight: 50-460gsm

Width: 1-1.8m

Roll length: 100 meters or customized

Weave Type:plain, twill

Material: fiberglass

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

Description: Kevlar® fabric is made by kevlar continuous filament fiber yarn. The kevlar is a famous brand of Dupont. Currently, there are available with K29, K49, part of K129 fabrics.

For economic purpose, we also supply China local supplier's para aramid fiber yarn.

Application: High strength lamination; Bulletproof; Fireproof

- Q: Can fiberglass fabric be used for making gaskets?

- Indeed, the utilization of fiberglass fabric is applicable in the production of gaskets. Renowned for its exceptional durability and ability to endure high temperatures, fiberglass fabric emerges as an optimal material for gaskets necessitating resilience against intense heat and pressure. This fabric guarantees a dependable seal and finds frequent application in domains demanding chemical resistance and long-lasting performance, including the automotive, aerospace, and industrial sectors. Moreover, the lightweight and flexible nature of fiberglass fabric enables effortless installation and facilitates adaptability to diverse gasket configurations.

- Q: Are there any specific cleaning or washing instructions for fiberglass fabrics?

- Yes, there are specific cleaning and washing instructions for fiberglass fabrics. When cleaning fiberglass fabrics, it is important to avoid any harsh chemicals or abrasive scrubbing, as they can damage the fabric's surface. Instead, it is recommended to use a mild detergent or soap mixed with water to gently clean the fabric. It is important to rinse the fabric thoroughly with clean water to remove any soap residue. Additionally, avoid wringing or twisting the fabric as this can cause it to lose its shape or stretch. Instead, gently squeeze out the excess water and lay the fabric flat to air dry. It is also advisable to avoid exposing fiberglass fabrics to direct sunlight for prolonged periods, as this can cause fading or damage to the fabric. Following these instructions will help maintain the integrity and longevity of fiberglass fabrics.

- Q: Can fiberglass fabric be used for insulation in clean rooms?

- Fiberglass fabric, indeed, finds great utility in clean rooms as an insulation material. Renowned for its remarkable thermal and acoustic properties, it is commonly employed for insulation purposes. Its remarkable resistance to heat transfer and capacity to diminish noise render it ideal for establishing a controlled and insulated atmosphere within clean rooms. Furthermore, fiberglass fabric boasts qualities such as being lightweight, long-lasting, and impervious to chemicals and moisture, all of which are crucial factors to consider in clean room applications.

- Q: Can fiberglass fabric be used for making shower curtains?

- Yes, fiberglass fabric can be used for making shower curtains. Fiberglass fabric is known for its durability, water resistance, and easy maintenance, making it a suitable material for shower curtains. It is resistant to mildew and mold, which are common issues in bathrooms, and can withstand the moisture and humidity present in shower areas. Additionally, fiberglass fabric is easy to clean and does not absorb water, preventing it from becoming saturated or developing unpleasant odors. Overall, using fiberglass fabric for making shower curtains can provide a long-lasting and hygienic solution for any bathroom.

- Q: Is fiberglass fabric resistant to tears and punctures?

- Yes, fiberglass fabric is generally known for its high resistance to tears and punctures. This is because fiberglass is a strong and durable material that is made from fine fibers of glass. These fibers are tightly woven together to create a fabric that is highly resistant to tearing and puncturing. Additionally, fiberglass fabric is often treated with special coatings or finishes that further enhance its tear and puncture resistance. However, it is important to note that the exact level of tear and puncture resistance can vary depending on the specific construction and quality of the fiberglass fabric.

- Q: Can fiberglass fabrics be used for reinforcement in concrete structures?

- Fiberglass fabrics, woven or knitted fibers of glass, have the capability to reinforce concrete structures. With their high strength and durability, they enhance the tensile strength and crack resistance of the concrete when incorporated. In certain applications, they serve as an alternative to traditional steel reinforcement. Their lightweight nature, non-corrosiveness, and ease of handling make them a suitable option for various concrete structures like walls, slabs, beams, and columns. Moreover, fiberglass fabrics provide additional benefits such as thermal and electrical insulation, as well as resistance to chemicals. However, it is crucial to select and design reinforcement materials based on specific project requirements and engineering considerations.

- Q: Glass fiber cloth can be made into handbags, requirements of high temperature 680 degrees or more

- There are many kinds of glass fiber fabric, you can choose as long as you choose, such as medium and high strength glass fiber cloth".

- Q: What are the different weave styles available for fiberglass fabric?

- Fiberglass fabric offers a variety of weave styles, each with its own distinct qualities and uses. Among the most popular are plain weave, twill weave, satin weave, and leno weave. 1. Plain weave, the most common style, features a straightforward over-under pattern. Warp yarns pass alternatively over and under weft yarns, resulting in a balanced and stable fabric. Its versatility makes it suitable for numerous applications. 2. Twill weave showcases a diagonal line pattern on the fabric surface. By passing the weft yarn over multiple warp yarns before going under one or more, twill weave fabrics offer superior strength and durability, making them perfect for high-performance applications. 3. Satin weave is known for its smooth and glossy appearance. The weft yarn passes over several warp yarns before going under one, creating a high number of floats and a silky texture. Satin weave fabrics are lightweight, flexible, and drape beautifully, making them ideal for achieving a refined and elegant finish. 4. Leno weave is a unique style that creates an open mesh structure. Adjacent warp yarns are twisted together and secured with a weft yarn, resulting in high porosity and excellent breathability. Leno weave fabrics are commonly used in filtration and composite reinforcement applications. These are just a few examples of the weave styles available for fiberglass fabric. The choice of weave depends on specific requirements, such as strength, weight, flexibility, and aesthetics.

- Q: Can fiberglass fabric be used for making soundproofing materials?

- Fiberglass fabric is capable of being utilized in the production of soundproofing materials. Its high density and capacity to absorb sound waves make it an exceptional material for sound insulation. When applied as a fabric, it can either be layered or wrapped around surfaces to effectively decrease noise transmission. In the construction industry, fiberglass fabric is frequently used to construct sound barriers in walls, ceilings, and floors. Moreover, it is employed in the automotive and aerospace sectors to minimize noise pollution. The fabric's ability to capture and absorb sound waves renders it an excellent choice for soundproofing materials. It is worth mentioning, however, that achieving optimal soundproofing outcomes may necessitate proper installation and the addition of supplementary layers.

- Q: Glass steel can be embedded parts

- Can be embedded normal.

Send your message to us

High Temperature Insulation Kevlar Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords