Silicone Rubber Coated Fiberglass Fabric for Thermal Insulation at High Temperatures

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRICE: USD12 per square meter

UNIT: square meter

MOQ: 500square meters

Width: 1m, 1.27m, 1.52m

Color: black

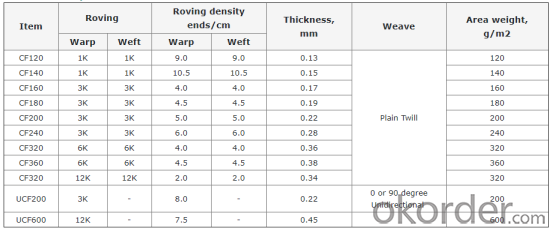

Weave Type:twill woven, plain woven

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

Description: Carbon fabric is woven by carbon fiber yarn available with 1K,3K,6K,12K, 24K. Carbon fiber is known as super high strength, modulus and light weight. It is a outstanding reinforce material. Depends on the various quality of carbon fiber, there are available various fabrics.

Features: High strength and modulus, Excellent resin and adhesive compatibility, Flexible customized specification

- Q: How does fiberglass fabric perform in high humidity environments?

- Fiberglass fabric performs well in high humidity environments. It is resistant to moisture absorption, which helps maintain its structural integrity and prevents it from becoming weak or deformed. Additionally, fiberglass is not affected by mold or mildew growth, making it a durable and reliable choice even in humid conditions.

- Q: Can fiberglass fabrics be used for insulation in HVAC ductwork?

- Indeed, insulation in HVAC ductwork can be achieved by employing fiberglass fabrics. The utilization of fiberglass fabrics in HVAC ductwork insulation is widespread, owing to their remarkable thermal attributes and fire resistance. By enveloping the ductwork with a layer of insulation, these fabrics facilitate the reduction of heat transfer and the prevention of energy loss. Furthermore, fiberglass fabrics boast a seamless installation process and the ability to be tailored precisely to meet the unique demands of the ductwork. Moreover, their durability and resistance to moisture render them appropriate for application in both residential and commercial HVAC systems.

- Q: How does fiberglass fabric perform in high-temperature environments?

- Fiberglass fabric performs well in high-temperature environments due to its excellent heat resistance properties. It can withstand temperatures up to 1000°F (540°C) without significantly degrading or melting. This makes it a suitable material for various applications such as insulation, fireproofing, and protective clothing in industries where high temperatures are present.

- Q: Is fiberglass fabric resistant to chemicals in oil and gas industry?

- Indeed, in the realm of the oil and gas industry, chemicals pose no threat to fiberglass fabric. Renowned for its extraordinary chemical resistance qualities, fiberglass fabric proves to be apt for a multitude of industrial uses, particularly within the oil and gas sector. Its resistance spans across a broad spectrum of chemicals, encompassing acids, alkalis, solvents, and hydrocarbons, which are frequently encountered in this industry. Furthermore, fiberglass fabric also demonstrates resistance against elevated temperatures, fire, and UV radiation, thereby establishing itself as a resilient and dependable material option for deployment in this field.

- Q: How is fiberglass fabric different from other types of fabric?

- Fiberglass fabric is different from other types of fabric primarily because it is made from woven glass fibers rather than natural or synthetic fibers. This gives it unique properties such as high strength, heat resistance, and insulating capabilities, making it suitable for various industrial applications. Additionally, fiberglass fabric is non-flammable, corrosion-resistant, and has low water absorption, setting it apart from traditional fabrics like cotton, polyester, or nylon.

- Q: How does fiberglass fabric perform in vibration damping applications?

- Fiberglass fabric is known for its excellent performance in vibration damping applications. This is due to its unique properties that make it an ideal material for absorbing and dissipating vibrations. Firstly, fiberglass fabric has high tensile strength, which allows it to withstand the forces exerted during vibrations without tearing or breaking. This ensures that it can effectively dampen vibrations over a long period of time without wearing out or losing its damping capabilities. Additionally, fiberglass fabric has a high modulus of elasticity, meaning it can resist deformation under stress. This property is crucial in vibration damping applications as it enables the fabric to absorb and dissipate the energy generated by vibrations, effectively reducing their intensity and preventing them from spreading to other components or structures. Furthermore, fiberglass fabric is lightweight and flexible, allowing it to conform to various shapes and surfaces. This versatility is advantageous in vibration damping applications as it enables the fabric to be easily installed and applied to different structures or components, ensuring efficient vibration reduction. Moreover, fiberglass fabric has excellent thermal stability and resistance to chemicals, making it suitable for use in diverse environments. Whether subjected to high temperatures, moisture, or corrosive substances, fiberglass fabric maintains its damping capabilities, ensuring long-lasting and reliable performance. Overall, fiberglass fabric performs exceptionally well in vibration damping applications due to its high tensile strength, modulus of elasticity, lightweight and flexible nature, thermal stability, and chemical resistance. Its ability to absorb and dissipate vibrations effectively helps in reducing noise, preventing damage to structures or components, and improving overall performance and longevity.

- Q: What is the width range of fiberglass fabric?

- The width range of fiberglass fabric can vary depending on the manufacturer and intended use. However, most commonly, fiberglass fabric is available in widths ranging from 30 inches to 60 inches. Some specialty fabrics may be available in wider widths, up to 100 inches or more. It is important to check with the specific manufacturer or supplier for the available width options for a particular fiberglass fabric.

- Q: What is the "three proof cloth"? How to correctly use the three proof cloth?

- Three cloth is coated on the surface of PVC, PTFE refractory fiber, flame retardant silicone and other refractory materials, make fire waterproof mildew proof function, refractory fiber with fire, PVC, PTFE, silica gel has a waterproof function.

- Q: How does fiberglass fabric perform in fire resistance?

- Fiberglass fabric is highly fire-resistant. It does not catch fire easily and can withstand high temperatures without melting or burning. It is often used in applications where fire safety is a concern, such as in fire curtains, protective clothing, and insulation materials.

- Q: Is fiberglass fabric resistant to chemicals used in aerospace industry?

- The chemicals used in the aerospace industry are not a problem for fiberglass fabric, as it is highly resistant to them. Fiberglass fabric is created by weaving strands of glass together, resulting in a material that is both strong and durable. This fabric is well-known for its ability to resist chemicals, which makes it suitable for a variety of uses in aerospace. Fiberglass fabric can handle exposure to different chemicals, such as fuels, lubricants, solvents, and hydraulic fluids, without suffering significant damage. This resistance to chemicals is crucial in aerospace, where the materials used must be able to endure tough conditions while maintaining their structural integrity. In conclusion, fiberglass fabric is an excellent choice for the aerospace industry because it possesses exceptional properties of chemical resistance.

Send your message to us

Silicone Rubber Coated Fiberglass Fabric for Thermal Insulation at High Temperatures

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords