Bio Geotextile High Permeability Polyester Spunbond Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Non Woven Polyester Geotextile Description:

Non Woven Polyester Geotextile Made from PET (polyester) short fiber by nonwoven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function.

technical parameter

Test | Unit | Standard/ Guaranted |

Mass per unit area | g/㎡ | 160/152.0 |

thickness | mm | 0.80/0.68~0.92 |

width | m | 3.8 |

Max. Tensile strength (MD) | KN/m | 12/10.2 |

Max. Tensile strength (CD) | KN/m | 11/9.2 |

Elongation at Max. tensile strength (MD) | % | 30.0/25 |

Elongation at Max tensile strength (CD) | % | /35.0/27 |

CBR bursting strength | KN | 1.8/1.5 |

shrinkage(MD) 200℃ | % | ≤1.7 |

shrinkage(CD)200℃ | % | ≤0.1 |

Elongation 3% Tensile strength(MD) | KN/m | 5/4.5 |

Elongation 15%Tensile strength(MD) | KN/m | 9/8.1 |

Elongation 3% Tensile strength(CD) | KN/m | 3.6/3.24 |

Elongation 15%Tensile strength(MD) | KN/m | 6.4/5.76 |

Trapezoid tearing strength | KN | 0.2 |

bitumen oil adsorption | L/㎡ | 0.8-1.2 |

Melting point |

Packaging & Shipping

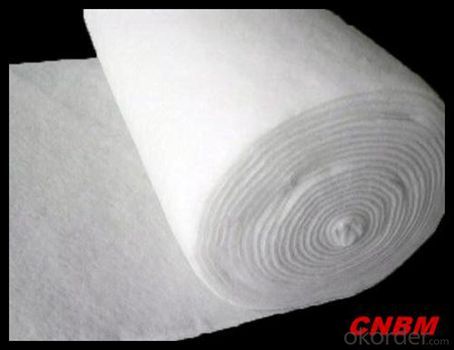

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Product Description:

Polyester Nonwoven Geotextile Specification:

No | Project | Index | ||||||

1 | Breakage Strength KN/m≥(MD) | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

2 | Breakage Strength KN/m≥(CD) | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

3 | Elongation Rate (MD,CD) ≤ | 28 | ||||||

4 | Trapezoidal Tearing Strength | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1.0 | 1.2 |

5 | Burst Strength KN≥ | 1.6 | 2.4 | 3.2 | 4.0 | 4.8 | 6.0 | 7.5 |

6 | Vertical Permeability Coefficient cm/s | 10-1~10-3 | ||||||

7 | Sieve size(O95) mm | 0.08~0.5 | ||||||

8 | Unit weight g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

9 | Thickness mm | 0.40 | 0.48 | 0.60 | 0.70 | 0.80 | 1.00 | 1.25 |

10 | Variation % | ±10 | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2:Can you send samples to us ?

A2:Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

Q3:What’s your Payment term ?

A3:T/T , L/C , Western Union,Paypal ...

Q4:What’s your manufacture process time ?

A4:Usually within 20 days

- Q: How do geotextiles help with slope stabilization?

- Geotextiles help with slope stabilization by providing reinforcement and retaining soil on slopes. They act as a barrier, preventing erosion and the movement of soil particles, while still allowing water to pass through. This helps to maintain the stability of slopes and prevents landslides or slope failures.

- Q: Is there a geotextile between the waterproofing membrane and the rigid layer?

- Need to prevent the waterproof layer from being pierced. Huazhi geotextile material manufacturers

- Q: Can geotextiles be used in wastewater treatment applications?

- Yes, geotextiles can be used in wastewater treatment applications. They are commonly used in filtration systems to separate solids from liquids and provide support for various treatment processes. Geotextiles can enhance the efficiency of wastewater treatment by improving filtration, reducing clogging, and increasing overall system performance.

- Q: Application standard of filament geotextile

- National standard for filament geotextiles GB / T-1998 Geosynthetics Filament anti - sticking acupuncture non - woven geotextiles, the latest standard GB / T - 2008.

- Q: Do you need to suture the lower geotextile of composite geomembrane?

- Need to suture, but the operation is more trouble.

- Q: What are the advantages of using geotextiles in mining operations?

- There are several advantages of using geotextiles in mining operations. Firstly, geotextiles act as a barrier, preventing the erosion of soil and rock particles, thereby reducing the potential for soil contamination and water pollution. Secondly, geotextiles can strengthen and stabilize the ground, providing increased support for heavy machinery and equipment used in mining operations. Additionally, geotextiles can be used to separate different layers of soil and rock, allowing for efficient drainage and filtration of water, which is crucial for maintaining the integrity of mining sites. Overall, the use of geotextiles in mining operations enhances environmental protection, improves operational efficiency, and ensures the safety of workers and surrounding ecosystems.

- Q: Can geotextiles be recycled?

- Yes, geotextiles can be recycled. They are typically made from synthetic materials such as polypropylene or polyester, which can be melted down and reused to create new geotextile products. Recycling geotextiles helps reduce waste and promotes sustainability in the construction and environmental industries.

- Q: How do geotextiles help in preventing the loss of aggregate in unpaved roads?

- Geotextiles are used in unpaved roads to prevent the loss of aggregate by providing stabilization and reinforcement. When placed between the soil and aggregate layers, geotextiles act as a barrier that allows water to pass through while retaining the aggregate, effectively preventing erosion and maintaining the road's integrity.

- Q: Geotextile with glue can stick cement wall

- With the wind oil fine soaked, wipe with a rag off.

- Q: Can geotextiles be used for erosion control in coastal dunes?

- Yes, geotextiles can be used for erosion control in coastal dunes. Geotextiles are permeable fabrics that can be placed on the dune surface to help stabilize the sand and prevent erosion caused by wind and water. They can be an effective solution for protecting coastal dunes and preserving their natural ecosystem.

Send your message to us

Bio Geotextile High Permeability Polyester Spunbond Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords