Spun-bond Polyethylene Nonwoven Geo-textile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

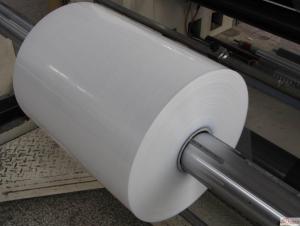

1.Structure of Geotextiles Description:

Geotextile, also called geotextiles, it is made of synthetic fiber by acupuncture or the permeability of woven geosynthetic materials. Finished products for cloth, width is commonly 4 to 6 m, length is 50-100 meters. Geotextile divided into woven geotextile and non-woven geotextile. Geotextile has excellent filtration and drainage, isolation, reinforcement, seepage control, protection, light weight, high tensile strength, good permeability, high temperature resistance, freezing resistance, ageing resistance, corrosion resistance properties.It is suitable for geotechnical engineering to meet the demand of the different characteristics, and form a geotechnical material industrial products series. Widely used in rivers, coast, harbor, roads, railways, docks, tunnels, Bridges and so on in the geotechnical engineering. It can meet a variety of different purposes.

2.Main Features of Geotextiles:

High tensile strengh,Corrision resistante.

Good permeability,Microbial resistance.

Light weight, low cost, corrosion resistance

Convenient for Construction.

3.Geotextile Specification:

| Gram(g/m2) | 100 | 200 | 300 | 400 |

| Thickness(mm) | 0.9 | 1.7 | 2.4 | 3.0 |

| Breaking strength(≥kN/m) | 2.5 | 6.5 | 9.5 | 12.5 |

| Tear strength≥(kN) | 0.08 | 0.12 | 0.24 | 0.33 |

Bursting strength≥(kN) | 0.3 | 0.9 | 1.5 | 2.1 |

4.Geotextile Images:

- Q: What is the impact of TPO waterproofing membrane welding performance?

- 2. The surface cleanliness of the web; 3. Does the welding temperature match the welding speed; 4. Welding method, test welding, manual three-step welding.

- Q: Waterproof electrode, waterproof welding

- 2, start welding should be in the vicinity of the weld without water at the arc. After the arc short arc quickly arc to the weld, with the arc to withstand some of the overflow. In the edge of the weld to form a pool after the arc immediately lead to the steel, the two sides together and gradually welded up. Under normal circumstances should be continuous arc, once the welding stopped, the tip of the electrode will not be able to lead the original arc

- Q: Surfacing isolation layer is the application of what, how to achieve surfacing isolation layer weld.

- Surfacing as a material surface modification of an economical and rapid process, more and more widely used in various industrial sector parts manufacturing repair.

Send your message to us

Spun-bond Polyethylene Nonwoven Geo-textile

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords