High Quality Sheet Metal Aluminum Sheets for Roofing Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets for Roofing with High Quality

Our aluminum sheets for roofing are good at ductility, heat conductivity, anti-corrosion and moisture resistance. They are widely used in roofing, electronics, instruments, lighting decoration, packing, decoration, curtain wall, sandwich panels, boats, etc.

Our aluminum sheets can meet the highest standards while save the cost. Our strong quality control term bring you the most-qualified products.

2.Main Features of Aluminum Sheets for Roofing with High Quality

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

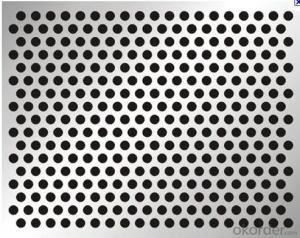

3. Aluminum Sheets for Roofing Images with High Quality

4.Specification of Aluminum Sheets for Roofing with High Quality

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5. FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Are aluminum sheets suitable for outdoor uses like fences or signs?

- <p>Yes, aluminum sheets are commonly used for outdoor applications such as fences and signage. Aluminum is lightweight, durable, and resistant to corrosion, making it ideal for outdoor conditions. It can withstand various weather elements without rusting. Additionally, aluminum can be easily formed into different shapes and sizes, and it's available in a wide range of colors and finishes, which makes it versatile for both functional and aesthetic purposes in outdoor settings.</p>

- Q: Can aluminum sheets be used for bus bodies?

- Yes, aluminum sheets can be used for bus bodies. Aluminum is a lightweight and durable material that is commonly used in the construction of bus bodies. Its high strength-to-weight ratio makes it an ideal choice for bus manufacturers, as it allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum is highly resistant to corrosion, which is beneficial for vehicles that are constantly exposed to various weather conditions. Moreover, aluminum can be easily formed and fabricated, allowing for the creation of complex shapes and designs. Overall, aluminum sheets are a popular choice for bus bodies due to their strength, lightness, corrosion resistance, and versatility.

- Q: Is it possible to use aluminum sheets for constructing a sustainable building?

- <p>Yes, aluminum sheets can be used to create a sustainable building due to their recyclability, low thermal conductivity, and durability. Aluminum is a lightweight material that can reduce the energy consumption in transportation and construction. It also has a high recycled content ratio and can be easily recycled, which reduces waste. Additionally, aluminum's low thermal conductivity can contribute to energy efficiency in buildings by reducing heat transfer, thus lowering energy costs for heating and cooling. However, it's important to consider the entire life cycle of the material and ensure that the manufacturing and disposal processes align with sustainable practices.</p>

- Q: how to avoid oxidation of aluminum sheet after wire drawing?

- leave it alone after wire drawing!aluminum sheet will formulate a layer of dense oxide film. So you don't need to worry about it! Don't often polish the aluminum wire, or they will be more and more slimsy, the oxide film is used for avoiding reoxidation.

- Q: Is it possible to use aluminum sheets for creating roofing tiles?

- <p>Yes, you can use aluminum sheets to make roofing tiles. Aluminum is a popular material for roofing due to its durability, lightweight, and resistance to corrosion. It can be shaped into various styles and sizes to mimic traditional roofing materials like clay or slate. Aluminum roofing tiles are also known for their energy efficiency, as they reflect heat and can help reduce cooling costs. However, it's important to ensure that the aluminum sheets are of good quality and installed correctly to achieve the desired performance and longevity.</p>

- Q: Can 101 aluminum sheets be painted or coated?

- Certainly! Aluminum sheets offer the possibility of being painted or coated. This adaptable material lends itself to receiving a range of finishes, including paint or protective coating, which can both elevate its visual appeal and safeguard it against corrosion. Whether it pertains to 101 aluminum sheets or any other aluminum variant, diverse techniques like spray painting, powder coating, or anodizing can be employed to paint or coat them. The selection of the appropriate paint or coating shall be contingent upon the desired aesthetics, performance criteria, and the precise utilization of the aluminum sheets.

- Q: What is the maximum width available for aluminum sheets?

- The maximum width available for aluminum sheets varies depending on the supplier and the specific requirements. However, standard widths for aluminum sheets typically range from 36 inches to 72 inches.

- Q: Can aluminum sheet be used for aerospace applications?

- Certainly, aluminum sheet finds application in the aerospace industry. Owing to its advantageous characteristics, including being lightweight, highly robust, and resistant to corrosion, aluminum is extensively employed in this sector. It is frequently utilized in the fabrication of aircraft fuselages, wings, and structural elements. Aluminum sheets are commonly employed in the production of aircraft panels, where their exceptional strength-to-weight ratio facilitates enhanced fuel efficiency and greater payload capacity. Furthermore, aluminum sheets offer versatility and suitability for a wide range of aerospace applications due to their ease of forming, machining, and welding.

- Q: Are aluminum sheets suitable for chemical processing?

- Yes, aluminum sheets are suitable for chemical processing. Aluminum is known for its excellent corrosion resistance, making it a popular choice for applications involving exposure to various chemicals. It forms a protective oxide layer that prevents further corrosion, even in harsh environments. Aluminum is also lightweight, which makes it easier to handle and transport in chemical processing industries. Additionally, aluminum is a good conductor of heat, allowing for efficient temperature control during chemical reactions. Overall, aluminum sheets are a suitable choice for chemical processing due to their corrosion resistance, lightweight nature, and good thermal conductivity.

- Q: How does the surface treatment affect the corrosion resistance of aluminum sheet?

- Surface treatment can significantly enhance the corrosion resistance of aluminum sheets. Processes such as anodizing, chemical conversion coating, and painting create protective layers on the surface, which act as barriers against corrosive agents. These treatments not only improve the durability and lifespan of the aluminum sheet but also enhance its ability to withstand harsh environmental conditions and prevent the occurrence of corrosion.

Send your message to us

High Quality Sheet Metal Aluminum Sheets for Roofing Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords