High Quality of Galvanized Steel Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coil are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

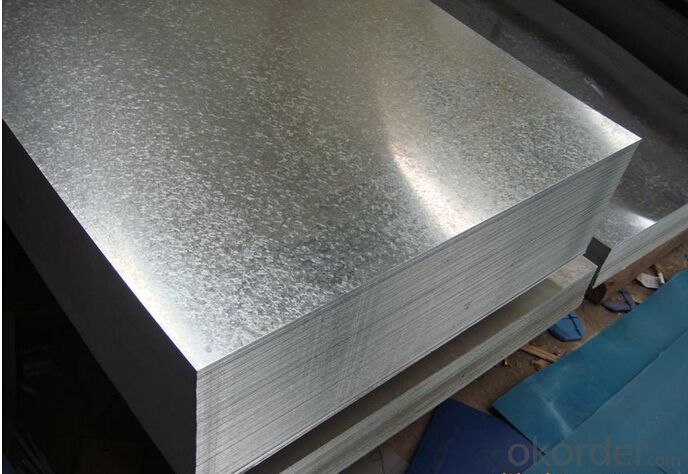

3.Hot-Dip Galvanized Steel Coil Images

4.Hot-Dip Galvanized Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: SPCC, SPCD, Q195, DX51D

Thickness: 0.15-5.0mm

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Application: Container Plate

Special Use: High-strength Steel Plate

Width: 600-1250mm

Length: depends

commodity: hot dipped galvanized steel coil

technique: cold rolled

thickness: 0.15-5.0mm

width: 600-1500mm

surface treatment: galvanized

zinc coating: 50-275g/m2

coil weight: 3-7 tons

coil ID: 508/610mm

spangle: zero spangle, regular spangle, small spangle, big spangle

payment term: by L/C or T/T

5.FAQ of Hot-Dip Galvanized Steel Coil

What’s the application of this product?

There are many applications for this product. For example, roofing, cladding, decking, tiles, sandwich walls, etc.

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: Can steel sheets be used for cladding?

- Yes, steel sheets can be used for cladding.

- Q: What is the process of polishing steel sheets?

- Achieving a smooth and shiny finish on steel sheets involves a series of steps. Firstly, the surface is cleaned to eliminate any dirt, oil, or debris, typically by employing a degreaser or solvent. Following this, abrasive materials like sandpaper or a sanding belt are utilized to sand the sheets, thus eliminating visible scratches and imperfections. Once sanded, a polishing compound or paste is usually applied and rubbed into the surface with a cloth or buffing wheel. This compound aids in removing any remaining scratches and revealing the natural shine of the steel. To further enhance the shine and smoothness, a finer polishing compound may be employed, repeating the process until the desired level of polish is achieved. Finally, the sheets are meticulously cleaned and inspected to ensure they meet the desired quality standards, including the removal of any remaining polishing compound residue and the identification of any remaining imperfections. In conclusion, the process of polishing steel sheets necessitates careful cleaning, sanding, and polishing to attain a smooth and shiny finish. The specific techniques and materials employed may vary depending on the desired level of polish and the type of steel being polished.

- Q: How do steel sheets perform in harsh chemical environments?

- Steel sheets generally perform well in harsh chemical environments due to their inherent strength and resistance to corrosion. However, the specific performance of steel sheets in such environments depends on factors such as the type and concentration of chemicals, temperature, and exposure duration. In some cases, additional protective coatings or treatments may be necessary to enhance the steel sheets' resistance to chemical corrosion.

- Q: How to introduce carbon steel plate?

- Grade: the cases of Q235-A F, said the sigma s Note: Q is more than 235MPa grade yield strength of A grade (ABCD four), F boiling steel characteristics: low price, process performance (such as welding and excellent cold formability). Applications: general engineering structures and general mechanical parts. Such as Q235 can make bolts, nuts, pins, hooks and less important mechanical parts, as well as the construction of the thread steel, steel, steel and so on

- Q: Can steel sheets be used for interior design purposes?

- Yes, steel sheets can be used for interior design purposes. They are commonly used for creating modern and industrial aesthetics in interior spaces. Steel sheets can be used for various applications such as wall paneling, room dividers, countertops, backsplashes, and decorative accents. Their durability, sleek appearance, and ability to be customized make them a popular choice for contemporary interior designs.

- Q: What are the weight considerations for steel sheets?

- Weight considerations for steel sheets vary depending on the specific application and desired outcomes. Here are a few key points to consider: 1. Thickness: The thickness of a steel sheet greatly affects its weight. Thicker sheets generally weigh more, while thinner sheets weigh less. It is important to choose a thickness that meets the structural requirements of the project while considering weight limitations. 2. Strength requirements: Different applications require steel sheets of varying strength levels. High-strength steel sheets are often thicker and heavier, while lower strength sheets can be thinner and lighter. Understanding the strength requirements of the project is crucial in determining the appropriate weight of the steel sheets. 3. Transportation and handling: The weight of steel sheets impacts their ease of transportation and handling. Heavier sheets require more labor and equipment for lifting, loading, and unloading. Moreover, transport vehicles have weight limits that need to be considered when selecting steel sheet sizes. 4. Structural limitations: The weight of steel sheets can affect the overall structural design. In some cases, lighter sheets may be preferred to reduce the load on supporting structures. However, in other scenarios, heavier sheets may be necessary to provide the required strength and stability. 5. Cost considerations: The weight of steel sheets can also impact the overall cost of a project. Heavier sheets typically cost more due to the increased material required and the additional handling expenses. Therefore, it is essential to strike a balance between weight, cost, and performance to optimize the project's budget. Overall, weight considerations for steel sheets are crucial in determining the appropriate thickness, strength, transportation requirements, structural design, and cost-effectiveness of a project. By carefully evaluating these factors, one can select steel sheets that meet the specific needs while ensuring the optimal weight for the desired outcome.

- Q: How do steel sheets perform in terms of load-bearing capacity?

- Steel sheets have excellent load-bearing capacity due to their high strength and durability. They can withstand heavy loads and distribute them evenly, making them an ideal choice for applications requiring structural support and resistance to deformation or bending.

- Q: What is the average yield strength of steel sheets?

- The average yield strength of steel sheets can vary depending on the specific grade and thickness of the steel being used. However, as a general range, the average yield strength of steel sheets typically falls between 250 and 600 megapascals (MPa). It is important to note that different steel grades, such as mild steel, high-strength low-alloy (HSLA) steel, or stainless steel, will have different average yield strengths. Additionally, the thickness of the steel sheet can also impact its yield strength, with thinner sheets generally having higher yield strengths. Therefore, it is crucial to consult the specifications and standards provided by the manufacturer or industry guidelines to determine the specific average yield strength for a particular steel sheet.

- Q: What is the process of stamping designs on steel sheets?

- The process of stamping designs on steel sheets involves using a custom-made die or mold that is pressed onto the steel surface with high force. This causes the design to be permanently imprinted onto the steel sheet.

- Q: Can steel sheets be used for making HVAC ducts?

- Indeed, it is possible to utilize steel sheets in the construction of HVAC ducts. Owing to its robustness, longevity, and fire-resistant attributes, steel is widely employed as a material for fabricating HVAC ductwork. To construct the ductwork, steel sheets are typically sliced, shaped, and fused together, enabling the efficient distribution of air throughout a structure. By employing steel sheets, the ducts can endure the elevated temperatures and pressures associated with HVAC systems, all while retaining their structural integrity. Furthermore, steel ducts exhibit increased resistance to harm caused by pests, moisture, and the growth of mold when compared to alternative materials. In summary, the reliability and capacity to meet the requisite performance standards make steel sheets a fitting choice for the production of HVAC ducts.

Send your message to us

High Quality of Galvanized Steel Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords