Best Quality of Galvanized Steel Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coil are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

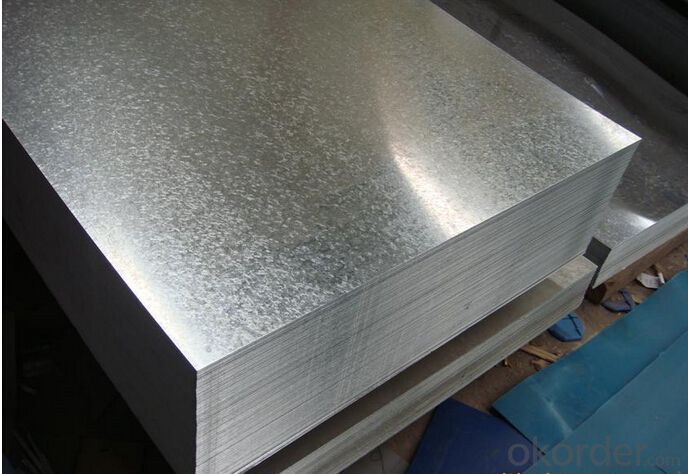

3.Hot-Dip Galvanized Steel Coil Images

4.Hot-Dip Galvanized Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: SPCC, SPCD, Q195, DX51D

Thickness: 0.15-5.0mm

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Application: Container Plate

Special Use: High-strength Steel Plate

Width: 600-1250mm

Length: depends

commodity: hot dipped galvanized steel coil

technique: cold rolled

thickness: 0.15-5.0mm

width: 600-1500mm

surface treatment: galvanized

zinc coating: 50-275g/m2

coil weight: 3-7 tons

coil ID: 508/610mm

spangle: zero spangle, regular spangle, small spangle, big spangle

payment term: by L/C or T/T

5.FAQ of Hot-Dip Galvanized Steel Coil

What’s the application of this product?

There are many applications for this product. For example, roofing, cladding, decking, tiles, sandwich walls, etc.

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: Are the steel sheets suitable for food-grade applications?

- Steel sheets are indeed appropriate for food-grade applications. The food industry frequently employs stainless steel due to its exceptional resistance to corrosion, long-lasting nature, and ease of maintenance. This material does not react with food and does not contaminate it with any hazardous substances, thus establishing its safety for food storage, processing, and transportation. Moreover, stainless steel can withstand high temperatures and endure rigorous cleaning and sanitization procedures, rendering it highly suitable for use in food-grade applications. Nonetheless, it is crucial to verify that the steel sheets meet the required food-grade standards and regulations prior to utilizing them in any food-related environment.

- Q: What is the difference between a coated and uncoated stainless steel sheet?

- A coated stainless steel sheet refers to a stainless steel sheet that has been coated with a protective layer or finish, which could be a polymer or another material. This coating serves to enhance the sheet's resistance to corrosion, scratches, and other forms of damage. The coating also provides a decorative or aesthetic appeal, as it can come in different colors or textures. On the other hand, an uncoated stainless steel sheet refers to a stainless steel sheet that does not have any additional protective layer or finish. It is in its natural state, with its inherent properties and characteristics. Uncoated stainless steel sheets are known for their high resistance to corrosion, durability, and strength. They are commonly used in applications where their natural properties are sufficient to withstand the intended environment. The main difference between coated and uncoated stainless steel sheets lies in their protective properties and appearance. Coated stainless steel sheets offer an extra layer of protection against corrosion and damage, making them suitable for environments where there is a higher risk of exposure to harsh conditions or corrosive substances. They also provide a wider range of design options due to their variety of coatings. Uncoated stainless steel sheets, on the other hand, are preferred in applications where the natural properties of stainless steel are sufficient to meet the requirements. They are often used in architectural and structural applications, as well as in industries such as food processing, pharmaceuticals, and medical equipment, where hygiene and durability are essential. In summary, the difference between a coated and uncoated stainless steel sheet lies in the additional protective layer and aesthetic options offered by the coating. Coated stainless steel sheets provide enhanced resistance to corrosion and damage, as well as a wider range of design choices, while uncoated stainless steel sheets rely on their inherent properties for durability and strength. The choice between the two depends on the specific application and the desired balance between protection, aesthetics, and cost.

- Q: Can steel sheets be used for signage purposes?

- Indeed, signage purposes can be served by steel sheets. Their durability allows them to withstand harsh weather conditions, rendering them appropriate for outdoor signage. Various sizes and designs can be achieved by cutting, shaping, and welding the steel sheets, offering versatility in crafting personalized signage. To enhance aesthetics and ensure long-lasting quality, the steel sheets can be painted or coated with different finishes. Moreover, their sturdiness enables secure mounting, making them an excellent choice for large and heavy signage installations.

- Q: What material is steel plate against drilling?

- All high nickel, high tungsten, or both titanium (tungsten carbide and titanium carbide), cobalt, molybdenum, niobium and other elements of the steel can be drilled.

- Q: What are the different types of steel sheet finishes for industrial applications?

- There are several types of steel sheet finishes commonly used in industrial applications, including hot rolled, cold rolled, galvanized, and coated finishes.

- Q: What are the different bending radius options for steel sheets?

- The bending radius possibilities for steel sheets can differ based on the thickness and type of steel used. In general, the bending radius for steel sheets ranges from 0.5 to 2 times the sheet thickness. For thinner sheets, such as those measuring 0.5mm to 2mm in thickness, it is typically advised to use a bending radius of 0.5 to 1 times the sheet thickness. This allows for a tighter bend without risking the steel cracking or deforming. For thicker sheets, like those measuring 2mm to 6mm in thickness, it is common to utilize a bending radius of 1 to 1.5 times the sheet thickness. This ensures that the steel retains its structural integrity and prevents excessive stress or strain during the bending process. For even thicker sheets, usually above 6mm in thickness, a bending radius of 1.5 to 2 times the sheet thickness is often necessary. This larger bending radius helps prevent any potential damage or distortion to the steel, ensuring a successful bending operation. It is important to note that these bending radius options are general guidelines and may vary depending on the specific grade, composition, and intended application of the steel. It is always recommended to consult the manufacturer's recommendations or seek expert advice when determining the appropriate bending radius for steel sheets.

- Q: What is the hardness of the wear-resistant steel plate?

- But not the higher the hardness, the better the wear resistance! The hardness is based wear resistant steel plate excellent wear resistance, but the relationship between the hardness and wear resistance is not proportional to the wear resistance; wear resistant steel plate, mainly because they have hard particles, and soft matrix, generally in the wear process, there will be some shedding substances, these substances will be integrated into the soft matrix that will not cause great harm to the surface; if the matrix hardness is relatively high, shedding of abrasive or other substances, the mutual movement will be mutual lapping, faster damage matrix!

- Q: Can steel sheets be bent without causing damage?

- Provided that the bending process is carried out with caution and within the material's limits, steel sheets can be bent without sustaining any damage. Various techniques, such as press brake bending or roll bending, are commonly employed to bend steel sheets. These methods involve applying controlled force and pressure to achieve the desired shape without causing any lasting deformations. Several factors influence the ability to bend steel sheets without harm. These factors include the thickness and grade of the steel, the bending radius, and the equipment and technique employed. Thinner sheets are generally more pliable and easier to bend, while thicker sheets may necessitate greater forces and specialized equipment. To ensure that the bending process does not exceed the steel's limits, it is crucial to consider its tensile strength, yield strength, and elongation properties. Over-bending can result in cracks, fractures, or permanent deformations that compromise the sheet's structural integrity. To prevent damage during the bending process, it is vital to follow proper bending techniques and guidelines. This includes using suitable tooling, distributing force evenly, and avoiding abrupt changes in direction or excessive bending angles. Additionally, preheating the steel sheet can enhance its pliability and reduce the risk of damage. In conclusion, steel sheets can be bent without damage, but it necessitates careful consideration of the material's properties, appropriate equipment, and adherence to bending guidelines. By employing the correct techniques and precautions, steel sheets can be successfully bent into various shapes and forms while preserving their structural integrity.

- Q: Are the steel sheets resistant to chemicals?

- Yes, steel sheets are generally resistant to chemicals due to their inherent durability and corrosion-resistant properties. However, the specific resistance can vary depending on the type of chemical and the grade of steel used. It is advisable to consult with manufacturers or experts to determine the suitability of steel sheets for specific chemical applications.

- Q: Can the steel sheets be used for insulation purposes?

- Typically, steel sheets are not employed for insulation purposes. Due to its high conductivity, steel easily transfers heat and cold. Consequently, it is ill-suited for insulation as it fails to effectively hinder the transfer of thermal energy. Conversely, insulation materials are explicitly designed to minimize heat transfer and enhance energy efficiency in buildings and other structures. Foam, fiberglass, and cellulose are examples of common insulation materials that exhibit significantly greater resistance to heat flow than steel.

Send your message to us

Best Quality of Galvanized Steel Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords