High Quality of Galvanized Steel Sheet of China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coil are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

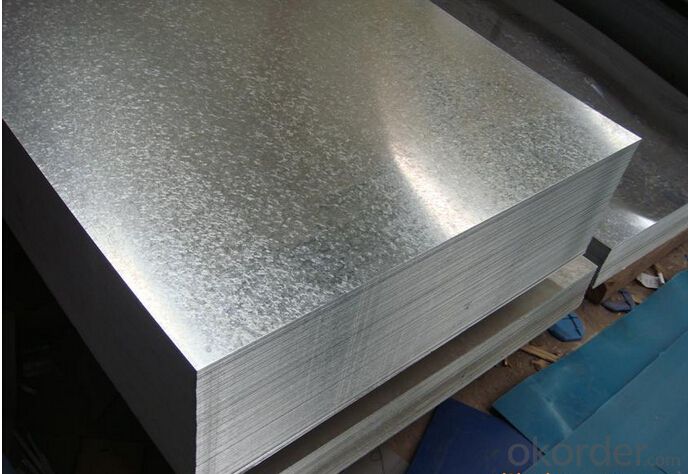

3.Hot-Dip Galvanized Steel Coil Images

4.Hot-Dip Galvanized Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: SPCC, SPCD, Q195, DX51D

Thickness: 0.15-5.0mm

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Application: Container Plate

Special Use: High-strength Steel Plate

Width: 600-1250mm

Length: depends

commodity: hot dipped galvanized steel coil

technique: cold rolled

thickness: 0.15-5.0mm

width: 600-1500mm

surface treatment: galvanized

zinc coating: 50-275g/m2

coil weight: 3-7 tons

coil ID: 508/610mm

spangle: zero spangle, regular spangle, small spangle, big spangle

payment term: by L/C or T/T

5.FAQ of Hot-Dip Galvanized Steel Coil

What’s the application of this product?

There are many applications for this product. For example, roofing, cladding, decking, tiles, sandwich walls, etc.

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: What are the dimensions of steel coils used in the storage tank industry?

- Steel coils used in the storage tank industry come in various dimensions, depending on the specific requirements of the tank being manufactured. Generally, these coils are available in different sizes and thicknesses. The width of the steel coils can range from approximately 600 millimeters to 2,400 millimeters. Similarly, the length can vary from a few meters to tens of meters. The thickness of the coils can also differ, typically ranging from 1.5 millimeters to 10 millimeters or more. Factors such as the size and capacity of the storage tank, the material being stored, and the structural requirements of the tank determine these dimensions. Consequently, the tank manufacturer or designer would determine the specific dimensions for a given storage tank project, following industry standards and project specifications.

- Q: What bike companies make the best Steel Road bikes?

- steel bikes are now mostly custom and expensive colnago lemond are factory [expensive] though giant doesn;t make them that i know of wle.

- Q: What are the different types of steel coil slitting methods?

- There are three main types of steel coil slitting methods: rotary slitting, loop slitting, and oscillating slitting. Rotary slitting involves using a circular knife to cut the coil into smaller strips. Loop slitting involves creating a loop in the coil and then cutting it using a straight knife. Oscillating slitting involves using a reciprocating knife to make a back-and-forth motion while cutting the coil. These methods allow for precise and efficient slitting of steel coils into narrower strips.

- Q: How are steel coils used in the manufacturing of food packaging?

- Steel coils are commonly used in the manufacturing of food packaging as they are shaped and formed into cans, containers, and lids, providing a strong and durable material for ensuring the safety and preservation of food products.

- Q: How are steel coils used in the manufacturing of garage doors?

- Steel coils are used in the manufacturing of garage doors as they provide the necessary strength and durability required for the door panels. These coils are formed into various shapes and sizes to create the panels, which are then coated and insulated to enhance their performance and appearance. The use of steel coils ensures that the garage doors are sturdy, long-lasting, and able to withstand the daily wear and tear associated with regular use.

- Q: How are steel coils used in the production of construction components?

- Steel coils are used in the production of construction components by being processed into various shapes and sizes, such as beams, columns, and plates. The coils are unwound and then cut, bent, or shaped to meet the specific requirements of the construction project. Additionally, the high strength and durability of steel make it a preferred material for construction, ensuring the components can withstand heavy loads and harsh environmental conditions.

- Q: What are the common problems faced during steel coil production?

- Some common problems faced during steel coil production include surface defects such as scratches or dents, dimensional inconsistencies, coil breakage, edge wave formation, and coil slitting issues. Other challenges may include coil corrosion, improper coil cooling, and quality control issues.

- Q: I like non-stick cookware but it dont hold up no matter how much money you spend. What isthe best kind? Is there something better then stainless steel or iron skillet? I do not care if I have to use extra elbow grease to clean a pan.

- Some utensils are both cookware and bakeware. The choice of material for cookware and bakeware items has a significant effect on the item's performance , particularly in terms of thermal conductivity and how much food sticks to the item when in use. Some choices of material also require special pre-preparation of the surface - known as seasoning - before they are used for food preparation. Stainless steel cookware is a great choice for safe cooking. Many kinds of cookware react with the foods, either changing the taste of the food or even releasing harmful materials into the food that can cause imbalances or diseases. Many non-stick coatings like teflon are safe - but once they get scratched or overheated they can start to leak chemicals in the food that are according to some scientific studies dangerous and possibly carcinogenic. Both the cooking pot and lid handles can be made of the same material, but will mean that when picking up or touching either of these parts oven gloves will need to be worn. In order to avoid this, handles can be made of non heat conducting materials, for example bakelite, plastic or wood. It is best to avoid hollow handles because they are difficult to clean or to dry.

- Q: What are the different methods of pickling steel coils?

- There are several methods of pickling steel coils, including the use of acid pickling baths, electrolytic pickling, and pickle lines. Acid pickling baths involve immersing the steel coils in a bath of acid solution, such as hydrochloric or sulfuric acid, to remove scale and impurities from the surface. Electrolytic pickling uses an electric current to remove the scale from the steel coils, while pickle lines involve passing the coils through a series of acid baths and rinses to clean and prepare the surface for further processing.

- Q: What are the different types of steel coil handling devices?

- There are various types of steel coil handling devices, including coil lifters, coil tongs, coil hooks, coil grabs, and coil carriages.

Send your message to us

High Quality of Galvanized Steel Sheet of China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords