Deformed Bars BS4449 B460B for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Deformed Bars BS4449 B460B for Construction

Description of Deformed Bars BS4449 B460B for Construction

1, Diameter: 5.5mm-10mm Deformed Bars BS4449 B460B for Constructionr

10m- 40mm Deformed Bars BS4449 B460B for Construction

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Deformed Bars BS4449 B460B for Construction

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

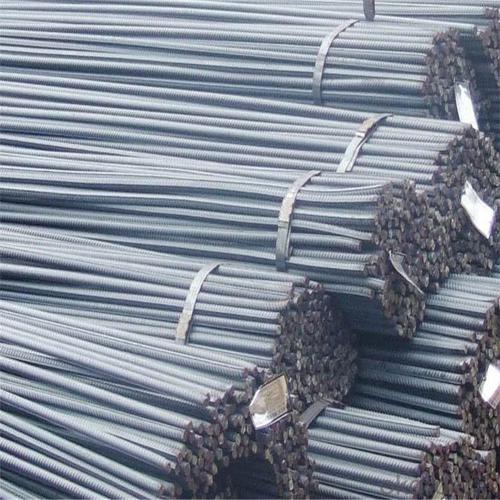

Products Show of Deformed Bars BS4449 B460B for Construction

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does heat treatment affect the properties of special steel?

- Heat treatment can significantly impact the properties of special steel. The process involves heating and cooling the steel in a controlled manner, which alters its microstructure, resulting in changes to its hardness, strength, toughness, and ductility. By carefully selecting the temperature and duration of heat treatment, desired properties such as improved hardness, increased strength, and enhanced wear resistance can be achieved. Additionally, heat treatment can also relieve internal stresses, enhance machinability, and improve dimensional stability of special steel.

- Q: How does stainless steel contribute to the automotive industry?

- Stainless steel contributes to the automotive industry by providing durability, corrosion resistance, and aesthetic appeal to various parts and components. It is commonly used in exhaust systems, engine components, body panels, and trim pieces, ensuring longevity and maintaining the integrity of vehicles even in harsh conditions.

- Q: How is special steel used in the aerospace manufacturing process?

- Special steel is used in the aerospace manufacturing process primarily for its strength, durability, and resistance to extreme temperature and pressure conditions. It is commonly employed in the construction of critical components such as turbine blades, landing gear, and structural parts of aircraft. The unique properties of special steel enable it to withstand the demanding environments and ensure the safety and reliability of aerospace systems.

- Q: How does special steel contribute to the pharmaceutical industry?

- Special steel plays a crucial role in the pharmaceutical industry by offering exceptional strength, corrosion resistance, and durability. It is used in the manufacturing of various equipment and components such as storage tanks, reactors, piping systems, and precision instruments. The unique properties of special steel ensure the integrity and purity of pharmaceutical products, prevent contamination, and enable efficient and safe production processes.

- Q: What are the advantages of using special steel in the renewable energy sector?

- Special steel offers several advantages when used in the renewable energy sector. Firstly, it provides enhanced strength and durability, allowing for the construction of robust and reliable components such as wind turbine towers and solar panel frames. This ensures prolonged operational life and increased resistance to harsh environmental conditions. Additionally, special steel exhibits excellent corrosion resistance, making it suitable for offshore wind farms and solar installations in coastal areas. Moreover, this type of steel can withstand extreme temperatures, enabling its use in concentrated solar power plants and geothermal energy systems. Overall, the use of special steel in the renewable energy sector enhances performance, extends lifespan, and improves the efficiency of renewable energy infrastructure.

- Q: What are the different methods of improving the corrosion resistance of special steel?

- Improving the corrosion resistance of special steel can be accomplished through several available methods. Some commonly utilized techniques include: 1. Alloying: Enhancing corrosion resistance can be effectively achieved by alloying the steel with specific elements. For instance, the addition of chromium forms a protective chromium oxide layer on the surface, acting as a barrier against corrosion. Other elements such as molybdenum, nickel, and copper can also be incorporated to enhance corrosion resistance. 2. Surface treatments: Various surface treatments can be employed to augment the steel's corrosion resistance. Galvanizing, for example, involves coating the steel with a layer of zinc, providing protection against corrosion. Another method, electroplating, deposits a thin layer of a more corrosion-resistant metal like nickel or chromium onto the steel surface. 3. Passivation: Passivation is a chemical process that eliminates free iron and other contaminants from the steel surface, resulting in the creation of a passive film that aids in corrosion resistance. This method is frequently used for stainless steel, in which a thin layer of chromium oxide is formed by treating the steel with an oxidizing agent such as nitric acid. 4. Protective coatings: The application of protective coatings on the steel surface significantly enhances its corrosion resistance. Various types of coatings, such as paints, epoxy coatings, and ceramic coatings, act as a barrier between the steel and the corrosive environment, preventing direct contact and corrosion. 5. Heat treatment: Heat treatment techniques, including annealing, quenching, and tempering, can alter the steel's microstructure, thereby enhancing its corrosion resistance. Heat treatment improves the steel's mechanical properties, reduces residual stresses, and eliminates impurities, all of which contribute to better corrosion resistance. 6. Design considerations: Proper design and construction techniques play a crucial role in improving the corrosion resistance of special steel. For instance, the elimination of sharp corners and crevices, the use of appropriate drainage systems, and ensuring proper ventilation can prevent the accumulation of moisture and corrosive agents. It is important to note that the selection of the most suitable method depends on the specific application, environment, and desired level of corrosion resistance. Optimal results can often be achieved by employing a combination of these methods.

- Q: What are the environmental impacts of special steel production?

- The environmental impacts of special steel production include emissions of greenhouse gases, such as carbon dioxide, during the manufacturing process. Additionally, the extraction and processing of raw materials for special steel production can contribute to habitat destruction, deforestation, and water pollution. Special steel production also consumes significant amounts of energy, contributing to fossil fuel depletion and air pollution.

- Q: How does special steel perform in high-temperature oxidation resistance?

- Special steel is specifically designed to have excellent high-temperature oxidation resistance. This type of steel contains alloying elements such as chromium, aluminum, and silicon, which form a protective oxide layer on the surface when exposed to high temperatures. This oxide layer acts as a barrier, preventing further oxidation and corrosion of the steel. The high-temperature oxidation resistance of special steel is crucial in applications where the material is exposed to extreme heat and oxidation, such as in gas turbines, heat exchangers, and furnaces. The protective oxide layer helps to maintain the integrity and strength of the steel, even under harsh conditions. Furthermore, special steel also exhibits excellent creep resistance at high temperatures. Creep refers to the gradual deformation of a material under a constant load and elevated temperatures. The unique composition of special steel provides it with the ability to resist creep deformation, enhancing its overall performance and reliability in high-temperature environments. In conclusion, special steel performs exceptionally well in high-temperature oxidation resistance due to its alloying elements and the formation of a protective oxide layer. Its ability to resist oxidation and maintain its structural integrity at elevated temperatures makes it a preferred choice for various industrial applications.

- Q: What are the requirements for special steel used in packaging machinery?

- The requirements for special steel used in packaging machinery can vary depending on the specific application and the type of packaging machinery being used. However, there are some common requirements that are typically expected for this type of steel. Firstly, the special steel used in packaging machinery should have excellent corrosion resistance. This is because packaging machinery often comes into contact with various liquids, including water, oils, and cleaning solutions. Corrosion resistance helps to prevent the steel from deteriorating or rusting when exposed to these substances, ensuring the longevity and reliability of the machinery. Secondly, the steel should possess high hardness and wear resistance. Packaging machinery often involves moving parts and components that are subjected to constant friction and wear. Therefore, the steel used in these parts should be able to withstand the repetitive contact and abrasion without undergoing significant wear or deformation. High hardness also helps to prevent the formation of scratches or grooves on the surfaces, which can compromise the quality of the packaging. Additionally, the special steel should have good machinability and formability. Packaging machinery often requires complex shapes and intricate designs, so the steel should be easily machinable and capable of being formed into the desired shapes and sizes. This facilitates the manufacturing process and allows for the creation of precise and accurate components. Furthermore, the steel should possess high tensile strength and toughness. Packaging machinery may be subjected to mechanical stresses and impacts during operation, and the steel used in its construction should be able to withstand these forces without fracturing or breaking. High tensile strength ensures the structural integrity of the machinery, while toughness helps to prevent the formation of cracks or fractures under sudden loads or impacts. Lastly, the special steel used in packaging machinery should be cost-effective and readily available. The cost of the steel should be reasonable and within the budget of the manufacturer, without compromising the quality or performance of the machinery. Additionally, the steel should be readily available in the market to ensure a continuous supply for manufacturing purposes. Overall, the requirements for special steel used in packaging machinery include corrosion resistance, high hardness and wear resistance, good machinability and formability, high tensile strength and toughness, and cost-effectiveness. Meeting these requirements ensures the durability, reliability, and efficiency of the packaging machinery in various industrial applications.

- Q: What are the different carburizing techniques used for special steel?

- There are several carburizing techniques used for special steel, including gas carburizing, liquid carburizing, pack carburizing, and vacuum carburizing. These techniques involve introducing carbon into the surface of the steel to improve its hardness and wear resistance. Gas carburizing involves heating the steel in a carbon-rich gas atmosphere, while liquid carburizing immerses the steel in a molten salt bath. Pack carburizing involves surrounding the steel with a carbon-rich compound in a sealed container. Vacuum carburizing is done in a low-pressure environment to minimize oxidation. Each technique has its advantages and is chosen based on the specific requirements of the steel and desired outcome.

Send your message to us

Deformed Bars BS4449 B460B for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords