Best Price For Aluzinc Steel EN 10125

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 50000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

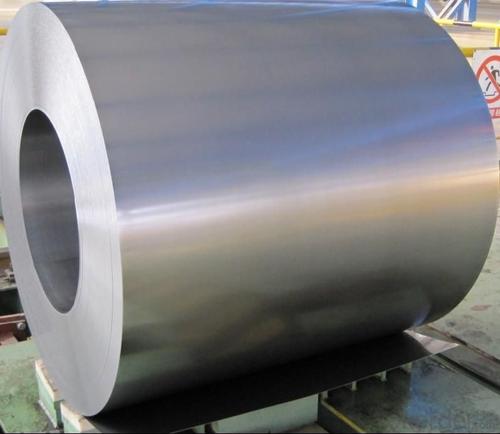

General Information Of Aluzinc Steel EN 10125

With Cold Rolled Steel as base metal,with the aluzinc coated, finally the plate steel is called galvalume steel. Galvalume steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

|

Thickness 0.25-4.0mm (BMT) |

|

Aluzinc Coating 50-150g/m2 |

|

Width 900-1250mm |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 4-8MT |

|

Quality Commercial and structural quality |

|

Surface Treatment Oiled or Dry, Chromated, Anti-finger,Non-skinpass,/ Skinpass |

|

Standard JIS G 3321, ASTM A792M, EN 10215 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Aluzinc Steel EN 10125

|

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

Technical Data Of Aluzinc Steel EN 10125

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out- of-Square |

Not exceed 1% Flatness |

|

Bow |

15mm max |

|

Edge Wave |

9mm max |

|

Centre Buckle |

8mm max |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Aluzinc Steel EN 10125

Aluzinc Steel can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliances.

Packaging & Delivery Of Aluzinc Steel EN 10125

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled with iron strips.

- Q: How is steel used in the production of amusement park rides?

- Steel is used in the production of amusement park rides due to its strength, durability, and ability to withstand heavy loads and forces. It is commonly used to construct the framework, supports, and tracks of roller coasters and other thrill rides, ensuring the safety and stability of the ride while providing a smooth and thrilling experience for riders.

- Q: How is steel made and processed to create various steel products?

- Steel is made through a process called steelmaking, which involves the conversion of iron ore into steel by removing impurities and adjusting the carbon content. This can be done through either the basic oxygen furnace or the electric arc furnace method. After steelmaking, the steel is cast into various shapes such as bars, plates, or coils. These forms are then further processed through techniques like rolling, forging, or extrusion to create a wide range of steel products, including beams, pipes, sheets, and automotive parts. The processing methods used depend on the desired shape, size, and properties required for the final steel product.

- Q: How is steel tubing used in the manufacturing of automobile exhaust systems?

- Steel tubing is commonly used in the manufacturing of automobile exhaust systems due to its durability, heat resistance, and cost-effectiveness. It is used to create the main body of the exhaust system, connecting the engine to the tailpipe. The steel tubing is responsible for carrying the hot exhaust gases away from the engine, preventing damage to other components and reducing noise. Additionally, steel tubing allows for the installation of catalytic converters and mufflers, which help reduce emissions and control noise levels. Overall, steel tubing plays a crucial role in ensuring the functionality and performance of automobile exhaust systems.

- Q: What are the different types of steel fasteners and their uses in the marine industry?

- There are several types of steel fasteners commonly used in the marine industry. Some of the most common ones include stainless steel bolts, screws, and nuts. These fasteners are highly resistant to corrosion, making them ideal for use in marine environments where they are exposed to saltwater and moisture. They are often used to secure various components of a boat or ship, such as railings, cleats, and fittings. Additionally, steel fasteners like snap hooks and shackles are used to connect ropes and chains, providing reliable and secure connections in the marine industry.

- Q: How is steel used in the manufacturing of water treatment systems?

- Steel is commonly used in the manufacturing of water treatment systems due to its durability and corrosion resistance. It is used to construct various components of these systems such as tanks, pipes, and frames. Steel ensures the structural integrity of the system and helps in withstanding the harsh conditions often found in water treatment processes.

- Q: What are the different types of steel forgings and their applications in the construction of power transmission lines?

- There are several types of steel forgings commonly used in the construction of power transmission lines. One type is the anchor forging, which is used to securely anchor the transmission towers to the ground. Another type is the crossarm forging, which provides support for the power lines and insulators. Additionally, there are pole line hardware forgings that are used for attaching the power lines to the transmission towers. These forgings are crucial for ensuring the structural integrity and stability of the power transmission lines, allowing for the efficient and reliable distribution of electrical power.

- Q: How do steel products contribute to the food and beverage industry?

- Steel products contribute to the food and beverage industry in several ways. Firstly, steel is commonly used in the construction of food processing plants and storage facilities due to its strength, durability, and resistance to corrosion. This ensures a hygienic and safe environment for the production and storage of food and beverages. Additionally, steel is utilized in the manufacturing of equipment and machinery used in food processing, such as mixers, conveyors, and packaging machines. These steel-made components are essential for various stages of food production, ensuring efficient processing, packaging, and distribution of products. Steel also plays a crucial role in the transportation and distribution of food and beverages. Steel containers, such as cans and drums, provide a secure and contamination-free packaging solution. Moreover, steel-made refrigerated containers and trucks help maintain the freshness and quality of perishable goods during transportation. Furthermore, stainless steel is widely used in kitchen equipment, utensils, and appliances. Its non-reactive nature and resistance to corrosion make it suitable for food preparation, cooking, and storage. Stainless steel surfaces are easy to clean, ensuring food safety and preventing cross-contamination. In summary, steel products contribute significantly to the food and beverage industry by providing the necessary infrastructure, machinery, equipment, and packaging solutions that ensure food safety, quality, and efficient production, storage, and distribution processes.

- Q: How do steel products contribute to the oil and gas industry?

- Steel products play a crucial role in the oil and gas industry by providing the necessary infrastructure and equipment to extract, transport, and process oil and gas. Steel pipes are used extensively for drilling, production, and transportation of oil and gas, as they offer high strength, durability, and corrosion resistance. Additionally, steel is used in the construction of storage tanks, refineries, and offshore platforms, providing the necessary strength and stability to withstand harsh environmental conditions. Overall, steel products are essential for the efficient and safe operations of the oil and gas industry.

- Q: How is steel used in the manufacturing of electrical equipment?

- Steel is commonly used in the manufacturing of electrical equipment for its durability and strength. It is used to construct the structural framework of equipment such as transformers, generators, motors, and electrical enclosures. Steel also provides a stable base for components and helps in heat dissipation, ensuring the safe and efficient operation of electrical equipment.

- Q: How is steel used in the construction of hospitals and healthcare facilities?

- Steel is commonly used in the construction of hospitals and healthcare facilities due to its strength, durability, and versatility. It is used for structural purposes, such as framing and support systems, as well as for roofing, cladding, and interior finishes. Steel's ability to withstand extreme loads and seismic forces ensures the safety and longevity of these critical facilities. Additionally, steel's non-combustible nature makes it a preferred choice, especially in areas where fire safety is crucial.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Price For Aluzinc Steel EN 10125

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 50000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords