High Quality Cold Drawn Laserable Aluminum Sheets Gold

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Cold Drawn Aluminum Alloy Plate Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Cold Drawn Aluminum Alloy Plate :

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

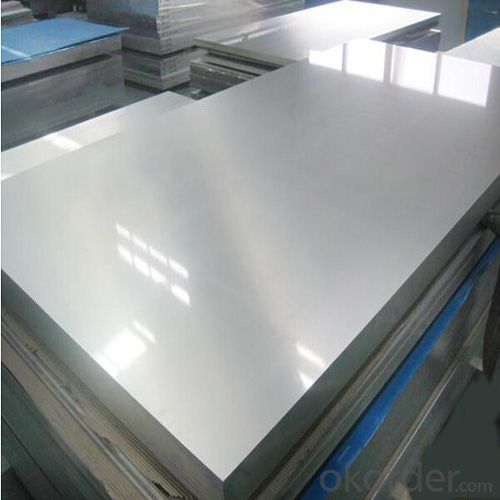

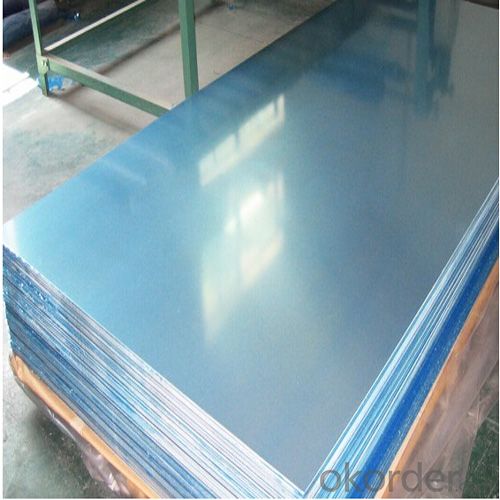

3. Cold Drawn Aluminum Alloy Plate Images:

4. Cold Drawn Aluminum Alloy Plate Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets suitable for electrical busbars?

- Electrical busbars can indeed be made from aluminum sheets. Aluminum is extensively used in the electrical industry due to its exceptional electrical conductivity, lightweight properties, and affordability in comparison to metals like copper. Aluminum sheets can be easily shaped and sized to fit the required dimensions for busbars, making them a versatile choice for electrical applications. Moreover, aluminum possesses commendable thermal conductivity, aiding in the dissipation of heat generated during electrical operations. However, it is crucial to acknowledge that aluminum has a lower electrical conductivity than copper, necessitating larger cross-sectional areas to achieve equivalent electrical performance. Consequently, it is vital to consider the specific requirements of the electrical system and seek expert advice to determine the suitability of aluminum sheets for a particular busbar application.

- Q: How much is the aluminum plate shearing machine?

- According to the model to decide, we'd better consult our manufacturers

- Q: Can aluminum sheets be used for electrical conductors?

- Aluminum sheets have the capability to function as electrical conductors. Despite being less efficient than copper, aluminum demonstrates good electrical conductivity. Nevertheless, owing to its lightweight properties, affordability, and resistance to corrosion, aluminum is frequently employed in various electrical applications. It finds extensive use in power distribution lines, wiring systems, and electrical equipment.

- Q: What is the typical flammability rating of aluminum sheets?

- Aluminum sheets typically have a flammability rating of Class A. This means that they are highly resistant to fire and will not easily ignite or contribute to the spread of flames. Aluminum is a non-combustible material, making it a popular choice for various applications where fire safety is a concern, such as construction, transportation, and aerospace industries. It has a high melting point and excellent heat dissipation properties, which further enhances its fire-resistant characteristics.

- Q: 1. Esrp for aluminum is -1.66V. Why is Al not reactive when dipped in cold water?2. Explain why the reaction between water and Al becomes more reactive when Al has been treated first with Mercury chloride.3. Aluminum hydroxide dissolve in both acid and base. What do you call this type of behavior?4. Describe the function of aluminum hydroxide in the testile industry.5. Aluminum sol. which contains [Al(H2O)6]3+ ions have the tendency to hydrolyze. Why? Recommend a method to prevent hydrolysis of aluminum ions.6. In the preparation of alum, sulphuric acid is added to the aluminum hydroxide sol. Why?

- 1) Aluminum forms a natural oxide coating in air that is very unreactive, so when you put it from air into water, nothing happens. 2) Mercury chloride reacts with the aluminum to form an amalgam (mercury-aluminum alloy) and is very reactive. 3) Amphoteric behavior 4) No idea. Check you textbook or class notes. 5) No idea. 6) To form aluminum sulfate

- Q: I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- In general terms, you will get a smoother, quieter better ride from the fiberglass than the aluminum. The fiberglass is heavier and will ride a little deeper in the water. Obviuosly, the aluminum will bounce off rocks better than the glass, but we usually try to avoid those situations. Also, resale will most likely be better on the good glass boats.

- Q: How do you calculate the weight of an aluminum sheet?

- To determine the weight of an aluminum sheet, one must take into account its dimensions (length, width, and thickness) as well as the density of aluminum. Initially, one should measure the length, width, and thickness of the aluminum sheet in either inches or millimeters. It is crucial to use a consistent unit of measurement throughout the calculation. Subsequently, if necessary, the dimensions should be converted to feet or meters. For instance, if the dimensions are in inches, divide each value by 12 to convert them to feet. To ascertain the volume of the aluminum sheet, multiply the length, width, and thickness together. In case the dimensions are in different units, they must be converted to the same unit before multiplying. Next, consult a reference for the density of aluminum. Aluminum's density is approximately 2.7 grams per cubic centimeter or 2700 kilograms per cubic meter. Convert the volume of the aluminum sheet to the same unit as the density. For example, if the density is in kilograms per cubic meter and the volume is in cubic feet, multiply the volume by 0.0283 to convert it to cubic meters. Lastly, multiply the volume of the aluminum sheet by the density of aluminum to determine the weight of the sheet. The resulting weight will be in grams or kilograms if the density was in grams per cubic centimeter, or in kilograms or metric tons if the density was in kilograms per cubic meter. It is important to note that this calculation assumes a uniform thickness throughout the aluminum sheet. If the sheet has varying thicknesses, one must calculate the weight of each section individually and then sum them to find the total weight.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, you can use aluminum sheets to create a green building. Aluminum is a sustainable material due to its recyclability and energy efficiency in production. It has a high recycled content rate, reducing the need for raw material extraction. Additionally, aluminum's lightweight nature can lead to reduced energy consumption in transportation and construction. Its durability and resistance to corrosion can extend the life of a building, further contributing to sustainability. However, it's important to consider the entire lifecycle impact, including the energy used in aluminum production, and to source aluminum responsibly to ensure a truly green building.</p>

- Q: 1) Aluminum ore is not formed in Quebec (why not?) 2)but aluminum ore is smelted into aluminum in Quebec. Why?

- The okorder

- Q: what's the difference between aluminum sheet detergent and central air-condition detergent?

- Central air condition cleaning includes air-cooled condenser cleaning and water-cooling condenser cleaning, if it’s air-cooled condenser cleaning, you can use aluminum sheet detergent.

Send your message to us

High Quality Cold Drawn Laserable Aluminum Sheets Gold

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords