Mechnical Diaphragm Dosing Metering Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mechnical Diaphragm Dosing Metering Pump

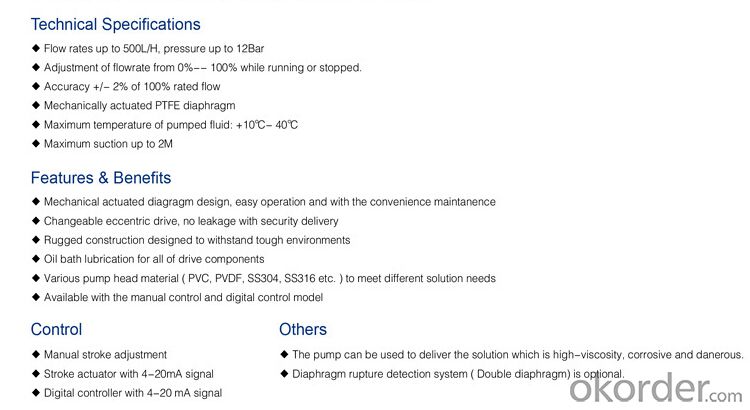

1.Structure of Mechnical Diaphragem Dosing Metering Pump

Mechnical Diaphragem Dosing Metering Pump offer the high performance with the max capacity flow upto 1200L/H and with outstanding value for pressure up to 12Bar.This series dosing pump is design for durability cost effiectiveness which is welcome to be used in lines such as water treatment,chemical,power,food and beverage,paper etc...

2.Main features of Mechnical Diaphragm Dosing Metering Pump

◆Mechincal actuated diagragm design

◆Power off seal,no leakage,with security delivery device,simple maintance

◆Easy operation

◆It can transport high-viscosity mediums, corrosive liquid and dangerous chemical goods.

◆The flow can be controlled via adjusting the length of stroke or the motor frequency.

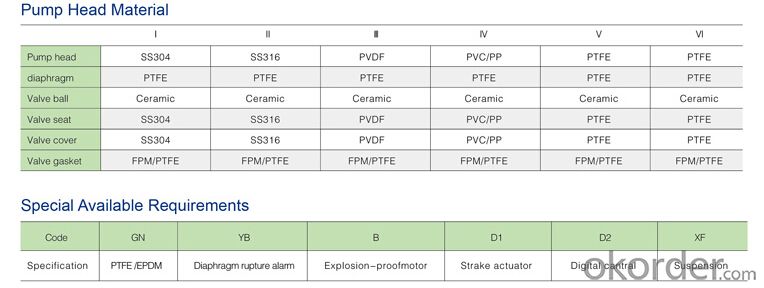

◆Verious pump head material(PVC,PVDF,SS304,SS316 etc..)

3.Mechnical Diaphragm Dosing Metering Pump Images

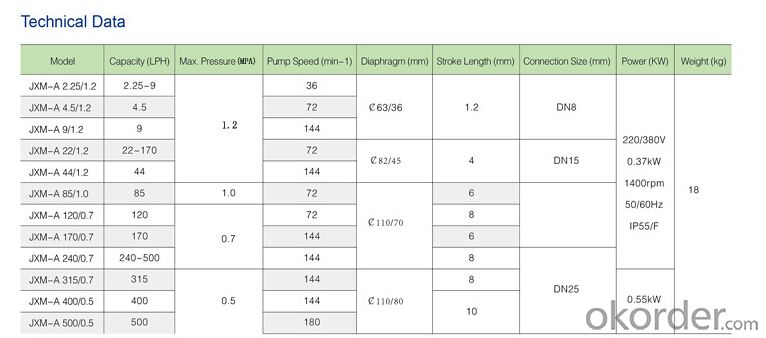

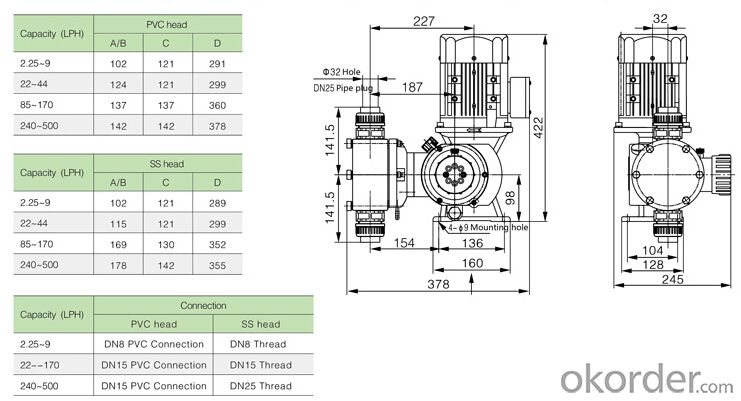

4.VSD Drive Mechnical Diaphragm Dosing Pump Specification

5.FAQ

·What is the delivery time?

within 20days

- Q: What is a water pump coupling device?

- The water pump coupling device comprises a coupler, a coupling flange, a guide rod and an upper fixing plate, wherein the contact surface of the coupling base and the coupling slide plate is provided with an annular groove, and a soft sealing gasket is tightly fixed on the groove. By adopting the structure, the coupling contact surface of the coupling slide plate and the coupling base is sealed firmly by an annular sealing groove

- Q: How can the submersible pump level meter be connected?

- Installation of submersible pumps dedicated liquid level float, connected to the submersible pump power line (some submersible pumps bought with), or received submersible pump control circuit, high starting, low stop.

- Q: How to install, operate and maintain the pipeline booster pump?

- Should be "People's Republic of China network security law" requirements, since June 1, 2017, the use of Internet services to carry out real name authentication account. In order to ensure your Baidu account can be used normally, please check the account number as soon as possible. Thank you for your understanding and support.How to install, operate and maintain the pipeline booster pump?Brother Yao s Gc76 2547 | browseRecommended for 2016-12-01 23:52:54 best answerThe installation of booster pump must be installed horizontally or vertically according to the installation method. The direction of flow shall be consistent with the arrow on the pump body, and installed as far away from the water level as possible. A valve shall be installed on the pump inlet line for ease of use and maintenance. When the impeller is the aspiration level below the pump on the pump shaft end or around the pump should be installed check valve, the outlet is connected with 13 links for water use, at first use to pump should be filled with water, and tighten the screw plug. The pipe connection should be tight, especially the water inlet pipe can not leak, otherwise it will reduce the pump head or not pumping water. The pump cavity is not water, not a long time running, so as not to damage the seal

- Q: How to distinguish the flow and displacement in the hydraulic pump? What's the difference between the two?

- The unit of displacement is the milliliter. How many milliliters does the pump rotate per circle? The displacement is the pump, the individual,The unit of flow is generally a liter, a figure added to the displacement of the pump over a period of time,

- Q: Why should I pump the pump before starting the centrifugal pump?

- 1., if it is backward flow, it is not pumping;2., if the pump is installed underwater (such as submersible sewage pump), it is not pumping;3. pump is for installation in the form of suction. If no diversion irrigation pump, then the pump is full of air quality, air density is less than water, the pump will not be inside the gas out, the pump pressure will not be far less than the atmospheric pressure, the water will not be pressed into the pump to pump through irrigation formed inside the closed environment, the pump will start water out will cause local vacuum, entrance external water pressure into the pump is in inside and outside differential pressure, complete water movement. (vacuum water diversion is directly through the vacuum pump pumping the air in the pump, resulting in internal and external pressure difference, the external water pressure in the internal and external pressure is press into the inlet of the pump. The principle is the same as the pump. A standard atmosphere of =10m water column.)

- Q: What is pump suction work?

- Pump is mainly used to transport liquid, including water, oil, acid and alkali liquid, emulsion, suspension emulsion and liquid metal, etc., also can transport liquid, gas mixture and liquid containing suspended solids.

- Q: What are the characteristics of a vertical multistage centrifugal pump?

- Vertical multistage centrifugal pump system using the latest international advanced IS type hydraulic model based design for high efficiency centrifugal pump with multi segment, the soft packing or mechanical seal, has the characteristics of high efficiency, large flow, high lift, no leakage, a wide range of performance, safe operation, stable operation and long service life and small area.

- Q: What is the function of a submersible pump?Do you have any knowledge about submersible pumps?.

- Important equipment for deep well water extraction. When in use, the whole unit dives into the water. The extraction of groundwater to the surface is water, mine rescue, industrial cooling, irrigation, water lifting, ship ballast, also can be used in fountain landscape, hot water submersible pump for hot spring bath, but also can be applied to the extraction of groundwater from wells, can also be used in rivers, reservoirs, canals and other water projects. The utility model is mainly used for farmland irrigation and water for human and livestock in mountain areas, and can also be used for central air conditioning cooling, heat pump units, cold pump units, cities, factories, railways, mines and site drainage. General flow can reach (10m3~650m3) per hour, head up to 1500 meters.

- Q: Is the flow meter in front of the pump or after the pump?

- After the flowmeter is placed in the pump, it is better to add a pressure tank or a buffer tank, so that the flow meter will work better

- Q: What is the difference between an air pump and a water pump?

- Pump performance of technical parameters are flow, suction, lift, shaft power, water power, efficiency, etc.; according to the different principles of work can be divided into volume pumps, vane pumps and other types. Displacement pump is to use its studio volume changes to transfer energy; vane pump is to use the rotating blade and water interaction to transfer energy, there are centrifugal pumps, axial flow pumps and mixed flow pumps and other types.

Send your message to us

Mechnical Diaphragm Dosing Metering Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords