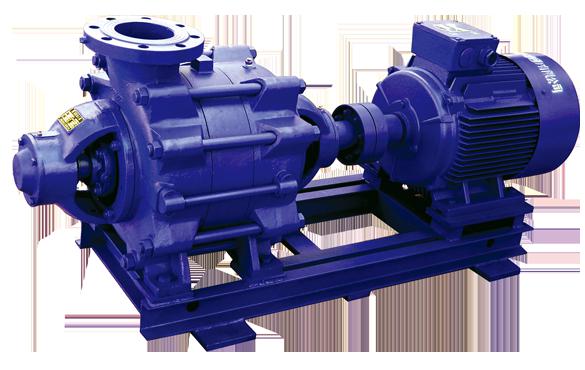

KQDW series horizontal single-suction multi-stage centrifugal pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product overview

KQD series multistage centrifugal pump is divided into KQDL vertical, KQDW horizontal multi-stage single export-oriented and KQDL vertical centrifugal pump, KQDW horizontal multi-stage export-oriented four more structure. Closer to the pump body of the new return pipe structure design, return pipe is not easy to damage, at the same time enhance the sealing of the pump. Instead of "O" ring rubber bellows mechanical seal is solved easily produce scale, jammed caused by mechanical seal leakage problem, quality is more reliable. Novel structure, superior quality; Running stability, avoid killed; Advanced design, save the investment; Unique parts and reduce the noise.

Application field

KQDL series multistage pump is my company according to the market need and development of series products, this product compared with similar products is small, the head difference between the same specification can be convenient for users to choose. This product is accord with GB/T 5657-5657 < < centrifugal pump technology conditions (Ⅲ) > > standard.

The working conditions

Speed: 1480/2950 r/min

Liquid: clean water or physical and chemical properties similar to water in the liquid.

Liquid temperature: 120 ℃ or less

Flow range: 3.7 ~ 200 m3 / h

Lift range: 12.1 ~ 240 m

The suction pressure of the maximum working pressure: maximum pressure 2.5 Mpa or less + pump

- Q: Know flow and lift how to calculate the pump power?

- N=Q.H.g. P / nN - motor power, kWH - pump head, MQ - pump flow, m^3/sG - gravity acceleration g=9.81

- Q: How much water does the water ring vacuum pump run for an hour? If there is no steam separator, does the water vaporize?

- Water ring vacuum pump is divided into many types, different sizes, different types, so water is different. As for how much water the no fixed amount, but to ensure that the water temperature is in 25 degrees, not more than 35 degrees can be.

- Q: How many millimeters is the diameter of the water outlet of the four inch pump?

- If it is a centrifugal pump, the nominal diameter of the outlet is less than 4 inches, there is a conical short tube to enlarge the standard 4 inch outlet flange, from here, is the standard 4 inch flange connection.

- Q: What is the lift of diaphragm pump?

- Tell you: diaphragm pump head is liquid through the pump energy obtained is called lift it, and flow and pump speed, a liquid density is generally 1 kg is 10 meters lift, horizontal pipeline 10 meters 1 meters lift, a 90 degree bend is 1 meters.

- Q: Shielding pump is the main drawback of electricity? How much does it cost more than an ordinary centrifugal pump? Is there any noise in the running of the canned pump? How much is it lower than the noise of the common centrifugal pump?

- The graphite bearing lubrication medium, make the operation less noise and manual, reduce maintenance costs; in recent years, bearing material added with silicon carbide SIC, super hard, life is better than that of graphite bearing.The vertical structure can be installed on the pipeline like a valve, the installation is convenient and quick, and the motor and the impeller can be drawn out only when the utility model is used, and the pipeline is not needed to be removed.The utility model can be installed and run with a shock absorber or a damping pad, so that the pump is less noisy at running time.

- Q: Rules for operation of centrifugal pumps

- Operating rules:1, before starting to check whether the water pump foot loose, coupling shield, and motor fan blade cover is intact, in order to ensure the safety of equipment and personal safety.2. Check whether the inlet valve is open and open as fully as possible. Is the outlet valve closed, open the bleeder valve, exhaust until there is no air, and close the bleeder valve. At the end of the valve to the pipeline in the pump cavity filled with water.

- Q: Harm of air pump and pump

- Centrifugal pump situationEmpty pump is divided into two kinds, if there is no liquid, then it will cause the mechanical seal of the pump to overheat, wear and even die

- Q: Direct connection pump What is straight pump and non direct pump? What's the difference in structure?

- What is straight pump and non direct pump? Direct coupled pump shaft and the motor shaft is directly coupled with the coupling and non direct coupled pump: pump shaft and motor shaft through the belt pulley, V-belt connection or other forms of transmission. What is the difference in the structure: the direct coupled pump has the advantages of compact structure, simple installation, but the relatively small power; non direct coupled pump: pump and motor is independent, the two transfer torque through the belt, the structure is relatively large, complex installation, general power is relatively large.

- Q: Why is the flow of the pump too small will occur cavitation phenomenon?

- Why is it easy to produce cavitation when the inlet flow of pump is lowered?This is because the main performance parameters such as the head, power and efficiency of the centrifugal pump are not fixed, but vary with the flow rate. The curve drawn on a coordinate paper is called the performance curve or characteristic curve of the centrifugal pump. What happens when the flow rate decreases? The disadvantage of throttling adjustment is that the pump flow is small, and the impeller is easy to cause cavitation

- Q: What is a vacuum pump for?

- In fact, the vacuum pump and high Swiss fan, high Swiss high-pressure blower, high Rui high-pressure pump principle is almost the same

Send your message to us

KQDW series horizontal single-suction multi-stage centrifugal pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords