Good Toughness Polyethylene & Polypropylene Geogrid High Modulus Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

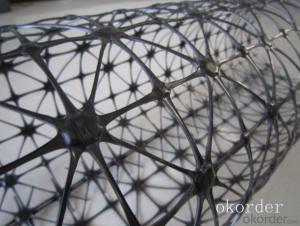

Geogrids form a distinct category of geosynthetics designed for reinforcement.

Fiberglass Geogrid with CE Certificate

We can produce fiberglass geogrid with tensile strength 30x30kn--300x300kn/m. mesh size can be 25.4x25.4mm or 12.7x12.7m ,50x50mm.

Type:

Geogrids

Material:

Fiberglass

Coating:

asphalt

feature:

High flexibility and large range

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geogrids improve the load transfer in road pavements?

- Geogrids improve the load transfer in road pavements by providing reinforcement and stabilization to the layers of the pavement. They are typically made of high-strength materials and are placed within the pavement layers to distribute the load more evenly, reduce deformation, and enhance the overall structural integrity of the road. This helps in preventing cracks, rutting, and other pavement distresses, ultimately extending the lifespan and improving the performance of the road.

- Q: How do geogrids enhance the performance of geocells?

- Geogrids enhance the performance of geocells by providing additional tensile strength and stability to the system. They help distribute loads more evenly, reducing the risk of deformation and improving overall load-bearing capacity. Geogrids also increase the confinement effect of the geocells, preventing soil and aggregate from shifting and improving overall stability.

- Q: Can geogrids be used in temporary construction access roads?

- Yes, geogrids can be used in temporary construction access roads. Geogrids are commonly used to reinforce and stabilize soil, making them an ideal solution for temporary roads that need to withstand heavy equipment and frequent use during construction projects.

- Q: Polypropylene geogrid

- Hello! ~ ~ ~ the so-called polypropylene is just a kind of material, the material has PP and polyethylene (HDPE) these two kinds

- Q: How do geogrids improve the performance of geotextile-reinforced retaining walls?

- Geogrids improve the performance of geotextile-reinforced retaining walls by providing additional strength and stability. They help distribute the load more evenly across the geotextile, reducing stress and potential failure points. Geogrids also prevent excessive lateral movement and improve overall structural integrity, increasing the retaining wall's ability to withstand external forces such as soil pressure.

- Q: What are the specifications of the geogrid

- Four kinds of glass fiber geogrid and polyester warp knitted polyester geogrid.

- Q: Geogrid and geotextile which effect is good

- Geotextile has excellent filtration, isolation, reinforcement and protection effect, high tensile strength, good permeability, high temperature resistance, anti freezing, anti-aging, corrosion resistance

- Q: What are the factors to consider when selecting a geogrid for a specific application?

- When selecting a geogrid for a specific application, several factors need to be considered. These include the desired strength and stiffness of the geogrid, the anticipated load and traffic conditions, the soil type and properties, the environmental and climate conditions, the installation and construction methods, and the project budget. Additionally, the compatibility of the geogrid with other materials and its long-term durability should also be taken into account. Ultimately, the geogrid chosen should be able to effectively reinforce and stabilize the soil, withstand the expected loads, and provide optimal performance for the specific application.

- Q: Steel wire mesh is a kind of geotechnical material

- The total area of the grille rib, rib steel wire grid as much as possible is less than the opening area, in order to ensure the mechanical occlusion compared with the interlocking effect. That is to say, to make the mesh as much as possible to bite the soil area, in order to give full play to the role of occlusion. But the mesh size should not be too large, otherwise the stiffness of rib is small, but the bite force decreased. Three. The ribs and ribs of the grid should be perpendicular to each other so as to transfer the load more effectively. If both are not vertical...

- Q: Can geogrids be used in soil reinforcement for landslide mitigation?

- Yes, geogrids can be used in soil reinforcement for landslide mitigation. Geogrids are commonly used to enhance the stability and strength of soil, including in slope stabilization and landslide prevention. They are placed within the soil mass to provide reinforcement and improve its load-bearing capacity, reducing the risk of landslides.

Send your message to us

Good Toughness Polyethylene & Polypropylene Geogrid High Modulus Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords