Coir Geotextile Machine Compatible High Density Polypropylene Geogrid for Highway, Railway, and Municipal Road Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

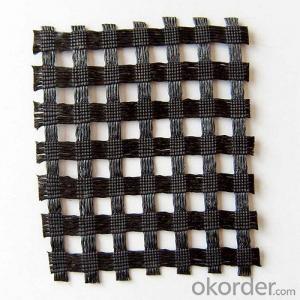

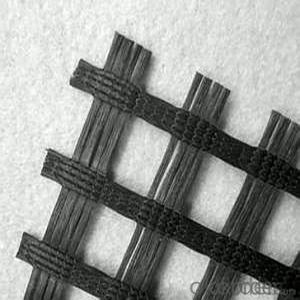

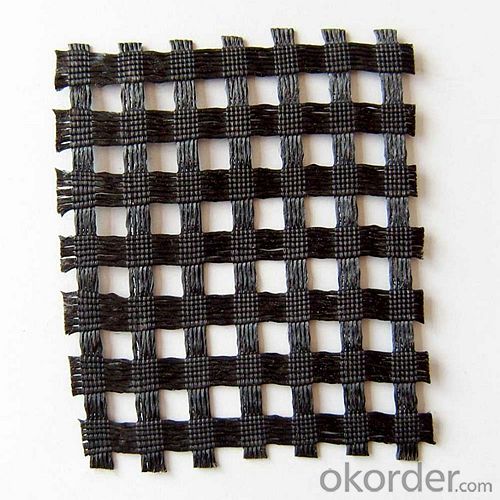

Geogrids form a distinct category of geosynthetics designed for reinforcement. These products are characterized by a relatively high tensile strength and a uniformly distributed array of large apertures (openings between the longitudinal and transverse elements). The apertures allow soil particles on either side of the installed sheet to come into direct contact, thereby increasing the interaction between the geogrid, aggregate and some soils. Also, the apertures ensure vertical drainage of a reinforced free-draining aggregate/soil.

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

OEM or Road

Model Number:

EGA50-50, EGA80-80, EGA100-100

Material:

Fiberglass

Coating:

asphalt

The geogrid elements vary in polymer type and cross-sectional dimensions. They can sometimes change shape and dimensions within their length. Geogrids are either integrally manufactured (punched and drawn sheets; or extruded), ultrasonically or adhesive bonded strips, or joined in a knitting or weaving process and then coated. Polymer types include polyethylene, polypropylene or high tenacity polyester that has been coated.

Although geogrids are used primarily for reinforcement, some products are designed for asphalt overlay and waterproofing or for separation and stabilization. Geogrids also are used as gabions and sheet anchors, inserted between geotextiles and geomembranes, or used to construct mattresses for fills or embankments over soft soils.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

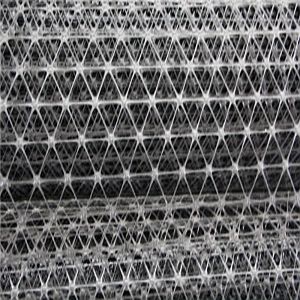

A: Yes, please check the pictures:

- Q: Can geotextiles be used in the construction of reservoirs?

- Yes, geotextiles can be used in the construction of reservoirs. Geotextiles are commonly used as a separation and filtration layer in reservoir construction to prevent the mixing of different soil layers, provide stability, and control erosion. They can be deployed to reinforce embankments, line channels, or act as a barrier against seepage, ultimately enhancing the overall performance and longevity of the reservoir.

- Q: What are the quality control measures for geotextile manufacturing?

- Some quality control measures for geotextile manufacturing include thorough testing of raw materials, regular inspections of production processes, and adherence to industry standards and specifications. Additionally, ensuring proper calibration and maintenance of manufacturing equipment, conducting quality checks at various stages of production, and implementing robust quality management systems are essential for maintaining the desired quality and performance of geotextile products.

- Q: What are the key factors affecting the hydraulic conductivity of geotextiles?

- The key factors affecting the hydraulic conductivity of geotextiles include the size and shape of the geotextile fibers, the porosity of the material, the thickness of the geotextile, and the applied pressure or load. Other factors that can influence the hydraulic conductivity include the type of soil or aggregate being filtered, the presence of any clogging materials, and the overall condition and integrity of the geotextile.

- Q: How do geotextiles improve the performance of drainage systems?

- Geotextiles improve the performance of drainage systems by enhancing filtration, preventing soil erosion, and promoting water flow, thus increasing the overall efficiency and longevity of the drainage system.

- Q: How to deal with the use of geotextiles under the roof

- Geotextile with drainage board below, the phone is the account number

- Q: Can geotextiles be used in flood protection projects?

- Yes, geotextiles can be used in flood protection projects. Geotextiles are often used as a component in flood control measures due to their ability to effectively filter and drain water while preventing soil erosion. They can be employed in various applications such as erosion control, slope stabilization, and shoreline protection, helping to mitigate the impact of floods and minimize damage to infrastructure and property.

- Q: How do geotextiles prevent soil erosion on slopes?

- Geotextiles prevent soil erosion on slopes by providing a stable and protective layer that helps retain the soil in place. These synthetic materials are placed on the slope and act as a barrier, preventing the soil from being washed away by rainfall or runoff. Geotextiles also promote proper drainage, allowing excess water to flow through while retaining the soil particles. This helps to maintain the integrity of the slope and reduce erosion caused by water movement.

- Q: Geotextile price is how much money

- Ask the geotextile price is too general, because the standard too much. Short wire, filament, polyester; non-standard, GB and so on. To Hongxiang Li Qian short wire geotextile price quote, for example, the price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan /Ton. 187 & lt; 6600 & lt; 5604

- Q: What are the advantages of using geotextiles?

- There are several advantages of using geotextiles. Firstly, geotextiles provide effective drainage and filtration, allowing water to pass through while preventing the movement of soil particles. This helps in preventing erosion and maintaining the stability of structures. Secondly, geotextiles can enhance the strength and performance of soil by acting as reinforcement. They can distribute loads and reduce stress on soil, making it more durable. Additionally, geotextiles can be used as a barrier to separate different soil layers or materials, preventing mixing and contamination. Lastly, geotextiles are lightweight, easy to install, and cost-effective compared to traditional construction materials, making them a versatile and efficient solution for various engineering and environmental applications.

- Q: Do geotextiles have any environmental benefits?

- Yes, geotextiles have several environmental benefits. They help in erosion control by stabilizing soil and preventing sediment runoff into water bodies. They also aid in vegetation growth by retaining moisture and promoting root development. Geotextiles can reduce the need for chemical herbicides and fertilizers by acting as a physical barrier against weed growth. Additionally, they can enhance the efficiency of drainage systems, reducing the risk of waterlogging and promoting groundwater recharge. Overall, geotextiles contribute to sustainable land management practices and help protect the environment.

Send your message to us

Coir Geotextile Machine Compatible High Density Polypropylene Geogrid for Highway, Railway, and Municipal Road Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords