High Tensile Strength Polypropylene Geogrids for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

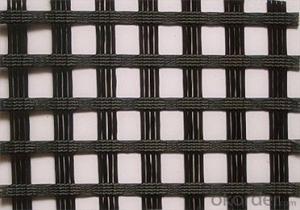

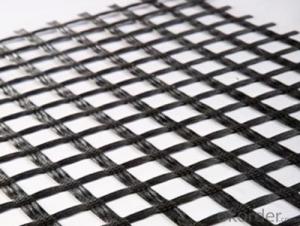

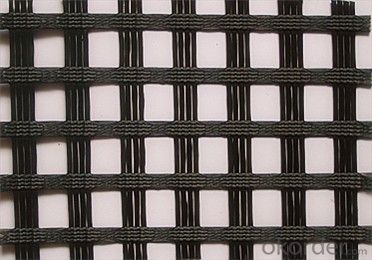

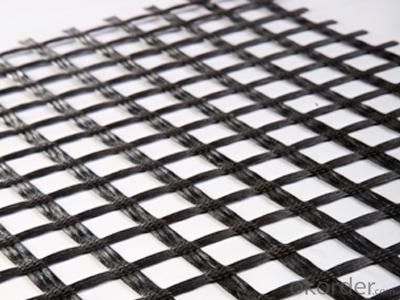

Structure of High Tensile Strength Polyester Geogrid:

High Tensile Strength Polyester Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of High Tensile Strength Polyester Geogrid:

fiberglass geogrid for soil reinforcement

fiberglass geogrid

Working & load transfer platforms

High tensile strength, low elongation

High stability

High Tensile Strength Polyester Geogrid Images

High Tensile Strength Polyester Geogrid Specification

Polyester Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How do geogrids improve the performance of flexible pavements?

- Geogrids improve the performance of flexible pavements by enhancing their strength and stability. They provide reinforcement and prevent the spreading of cracks and ruts, increasing the pavement's resistance to traffic loads. Additionally, geogrids help to distribute the load more evenly across the pavement, reducing the potential for deformation and extending its lifespan.

- Q: How do geogrids help in reducing the risk of pavement rutting?

- Geogrids help in reducing the risk of pavement rutting by improving the structural integrity of the pavement. They are placed within the pavement layers to distribute the load more evenly, increasing the pavement's resistance to deformation and rutting. The geogrids create a reinforced layer that enhances the load-bearing capacity and stability of the pavement, preventing the formation of ruts and prolonging its lifespan.

- Q: What are the procedures for using two-way geogrid

- 4 bidirectional geogrid used to prevent cracks in culvert.5 bidirectional geogrid is used to enhance soil slope and prevent soil erosion.6 bidirectional geogrid used to reduce the thickness of cushion, saving cost.7 bidirectional geogrid for stability of slope greening environment support grass mat.

- Q: What is the recommended overlap distance for geogrid seams?

- The recommended overlap distance for geogrid seams varies depending on the specific application and manufacturer's guidelines. However, in general, a minimum overlap distance of 12-18 inches is often recommended to ensure proper connection and strength of the geogrid.

- Q: Are geogrids suitable for reinforcement of railway ballasts?

- Yes, geogrids are suitable for reinforcement of railway ballasts. Geogrids provide excellent stabilization and reinforcement properties, reducing the lateral movement of ballast particles and increasing the overall stability of the railway tracks. They effectively distribute the load and enhance the strength of the ballast, resulting in improved track performance, reduced maintenance needs, and increased lifespan of the railway infrastructure.

- Q: How do geogrids help in reducing the risk of differential settlement of structures?

- Geogrids help in reducing the risk of differential settlement of structures by providing reinforcement and improving the load-bearing capacity of the soil. They act as a stabilizing layer, distributing vertical and horizontal forces evenly, which prevents uneven settling of the foundation. This helps maintain the structural integrity of the building and minimizes the potential for damage or structural failure.

- Q: What are the design guidelines for geogrid-reinforced retaining walls?

- Design guidelines for geogrid-reinforced retaining walls include considering factors such as soil properties, wall height and slope, geogrid type and spacing, construction methods, and drainage. The design should ensure proper stability, prevent excessive deformation, and provide adequate drainage to withstand lateral earth pressures. It is crucial to follow industry standards and guidelines, conduct thorough site investigations, and consult with experienced engineers to ensure a safe and efficient design.

- Q: Can geogrids be used in road construction?

- Yes, geogrids can be used in road construction. Geogrids are often used as a reinforcement material in road construction projects to improve the strength and stability of the roadbed. They help to distribute the load and prevent the movement of soil or aggregate materials, thereby enhancing the longevity and performance of the road.

- Q: How do geogrids enhance the performance of flexible retaining structures?

- Geogrids enhance the performance of flexible retaining structures by providing reinforcement and stability to the soil. They distribute the loads more evenly, reducing the stress on the structure and increasing its overall strength. Geogrids also prevent soil erosion and improve drainage, ensuring the long-term integrity and durability of the retaining structure.

- Q: Are geogrids suitable for use in landfill liners?

- Yes, geogrids are suitable for use in landfill liners. Geogrids are commonly used in landfill liner systems to enhance stability and prevent lateral soil movement. They provide reinforcement, improve drainage, and increase the overall performance and longevity of the landfill liner.

Send your message to us

High Tensile Strength Polypropylene Geogrids for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords