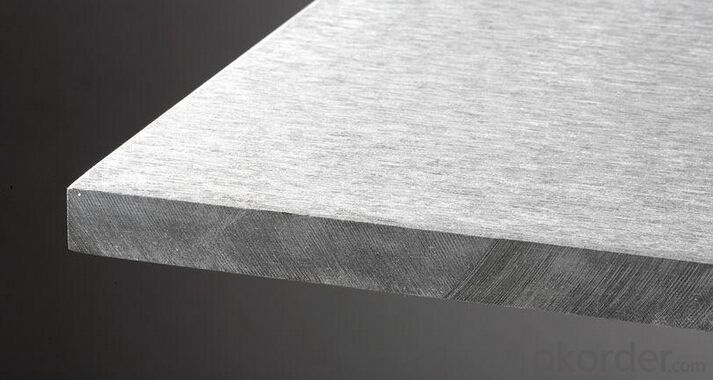

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Density and Strength fiber cement board is a high quality calcium silicate architectural board reinforced with selected cellulose fibres and fillers.

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives.

It is 100% free from asbestos, sepiolite, inorganic fibres or formaldehyde.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

Images:

- Q: Can cement tiles be directly on the cement board? What material is good?

- If you want to paste a small area can be directly on the cement board tiles, but to use plastic. If it is a large area must be linked to the net brush paste and then tiling, so that will not crack off after the use of cement mortar.

- Q: I bought some plaster which is to be used for a wall stenciling project. Is this type plaster ok to use to stick tiles on the kitchen wall as well? I PLAN TO REMOVE THE TILES WHEN WE MOVE, so thought this type of plaster may--or probably will be easy to work with when removing the tiles later in a year or two? Please advise, thanks

- I dont think your plan is wise. Go to a home depot, and ask them what you need. Personally, if its in an area that will get wet at all, I would use a concrete wallboard. Also ask at home depot what they think of this temporay tiles thing, prolly not much.

- Q: i am wondering the durablability difference. Is one more sturdier than the other?

- cement siding is easier to put up and quicker to put up. Both will provide the same protection if put up properly.

- Q: How to install the solution of cement pressure plate

- The following is the package of the construction method of classification, comparison brick: by the mud construction, in front of the brick, with red brick, the riser wrap up. Features: sound insulation is good, strong and strong, not easy to deformation, paste the disk is not easy to fry. Disadvantages: relatively thick, accounting for space.

- Q: Why does the fire burn on the cement board for a long time?

- Cement is a bad bad conductor, prolonged heating will be uneven due to uneven heating caused by uneven expansion, eventually leading to explosion

- Q: How does the cement pressure plate interface

- The corners of a corner, such as the four corners of a square room

- Q: do i need to put down cement board on concrete before laying tile?

- No okorder /i.html?_nkwtile+un...

- Q: are you able to mountain board not only on dirt but also on surfaces like cement, for ex: a street?

- you probably could

- Q: Can i tile over plywood floor, without using cement board?

- it is not the proper way to do it im guessing someone at home depot told you to use cement board but if your tiling not with sticky tiles it will work perfectly fine. me and my mom done it with exterior tiles on a back porch which is not heated if your using it for something thats going to be wet alot also if your doing this for something thats going to last do it the right way . for example our back porch is done without cement board the grout cracked in a few spots and a tile broke because of an accident also some tiles are not stuck to the floor they came up and we used a good amount of tile adhesive our front porch is done with cement board and its even in a colder climate in winter and is flawless.

- Q: I'm installing a stone back splash behind my bathroom sink - 16 SF. The wall is currently painted and I want to make sure that the stone and thinset adhere properly. Should I sand the wall with 80 grit sandpaper and apply the thinset/stone or should I put 1/2 or 1/4 plywood down for better adhesion? Perhaps cement board?

- Ideal way is to do a cement board as a backer board but since its in a non wet area,( not exposed to direct water) you really don t have to.Roughing the area up is always a good idea and won t hurt a thing. I d never do a wood backer in a moist and humid environment, It can expand from moisture and break the bond. Any questions you can e amil me through my avatar and check my qualifications there. GL

Send your message to us

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords